Hi Guys,

After giving it much thought, I decided I am going 20VE. Below is the build list (parts have been purchased).

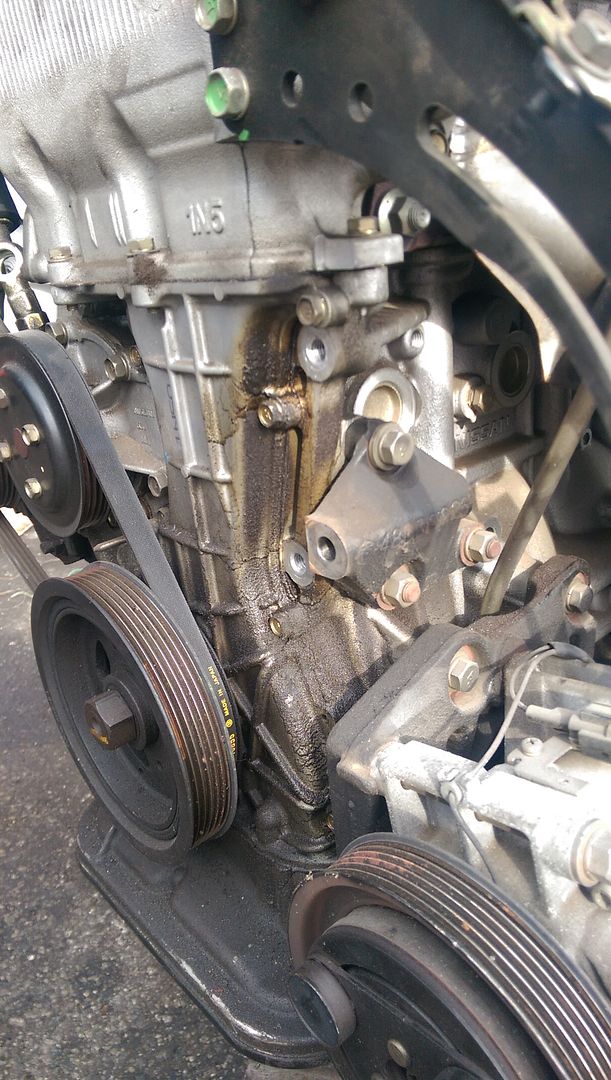

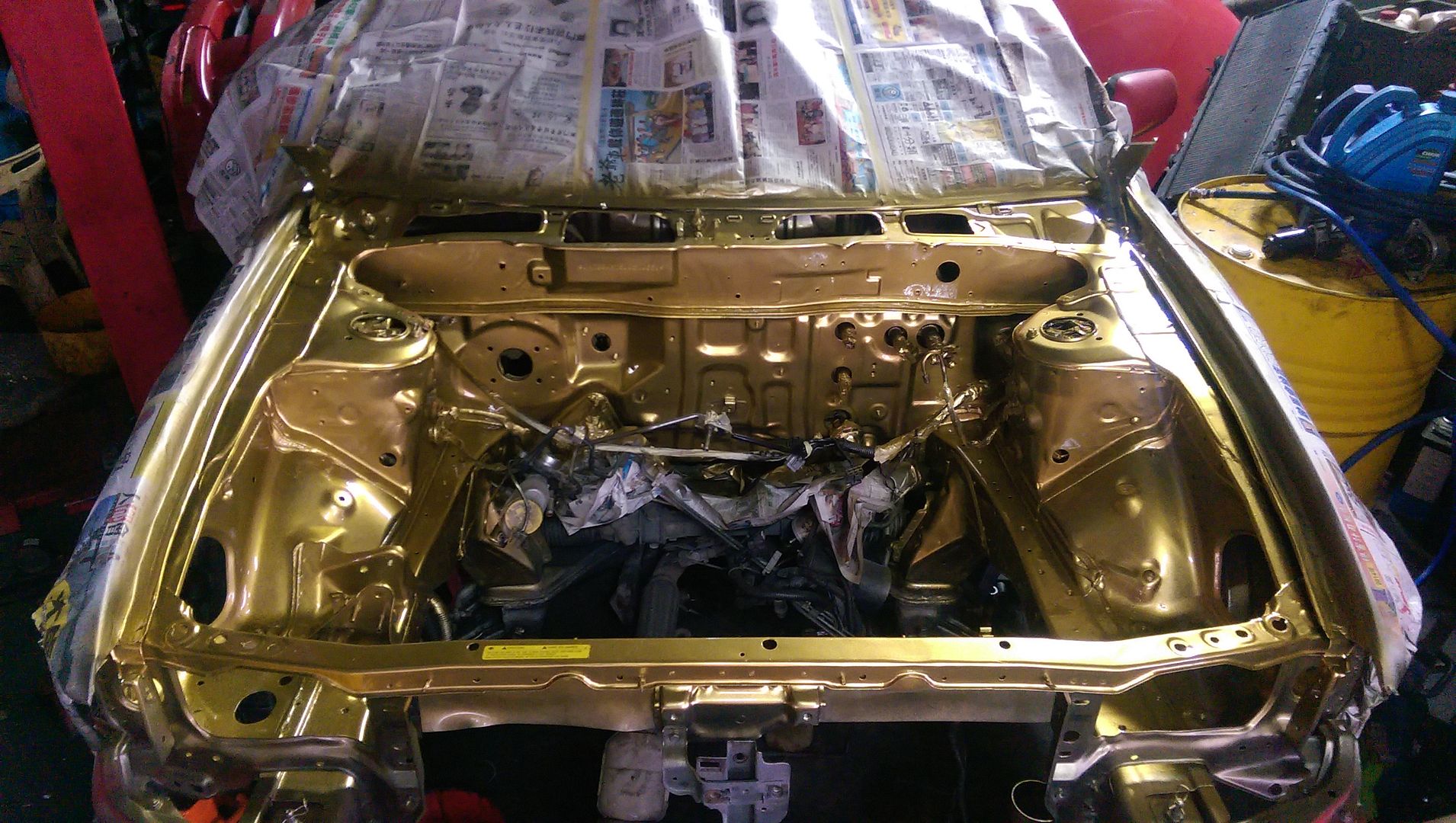

COMPLETE SR20VE Engine (done 34000Kms)

N1 CAMS

SR16VE (SERIE SRV) LSD Gearbox + Flywheel

ACT 240ft/lbs Clutch Kit.

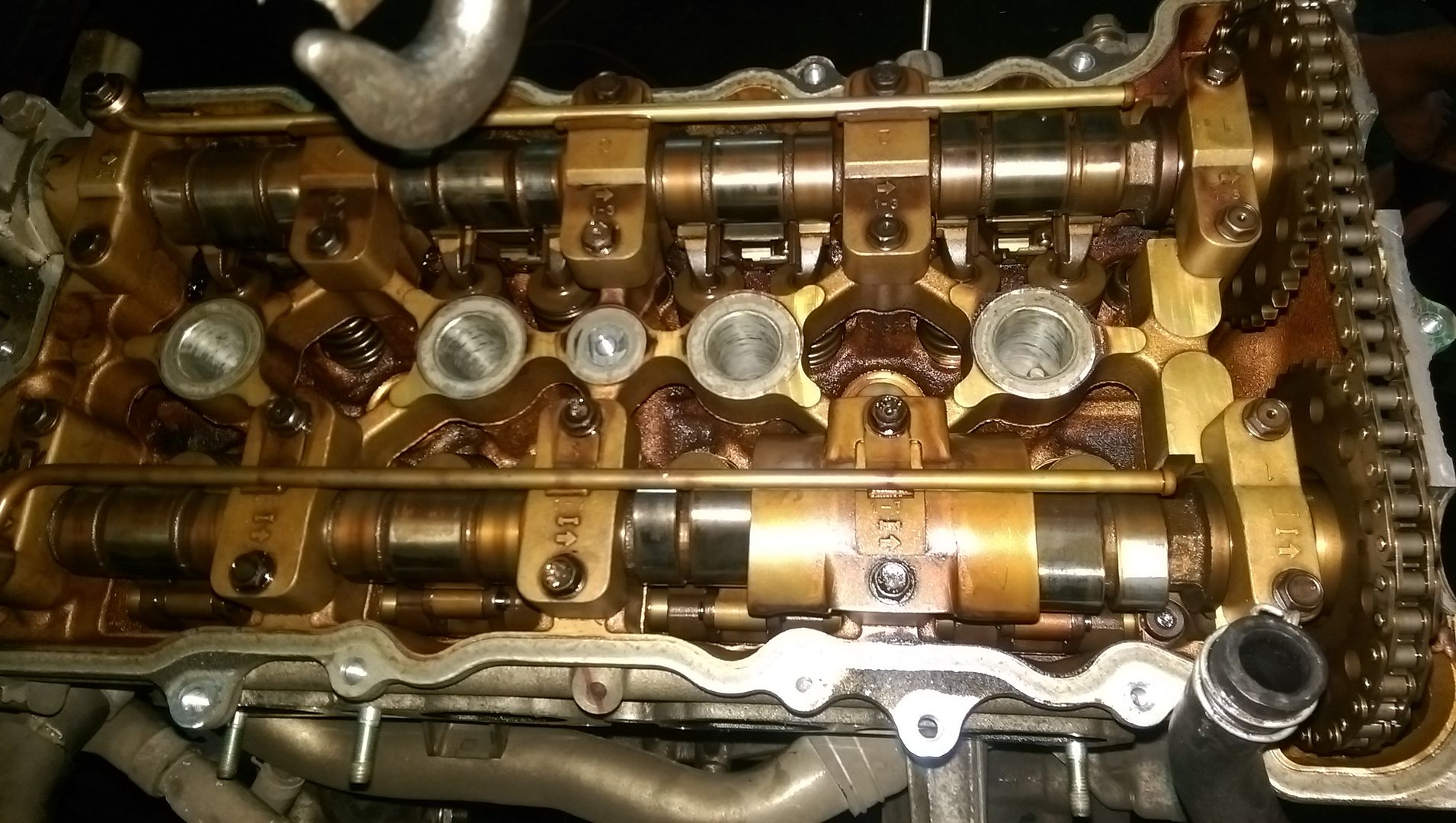

Head will be removed, and prepped (with stock valves and spring) :-

PORTnPOLISH with port match and bench flowed.

Multi angle Valve Job.

Very,very,very Mild Skimming (diamond tip)

Supertech Valve Guides and Seals (i dont think I need this since the engine is 34000kms)

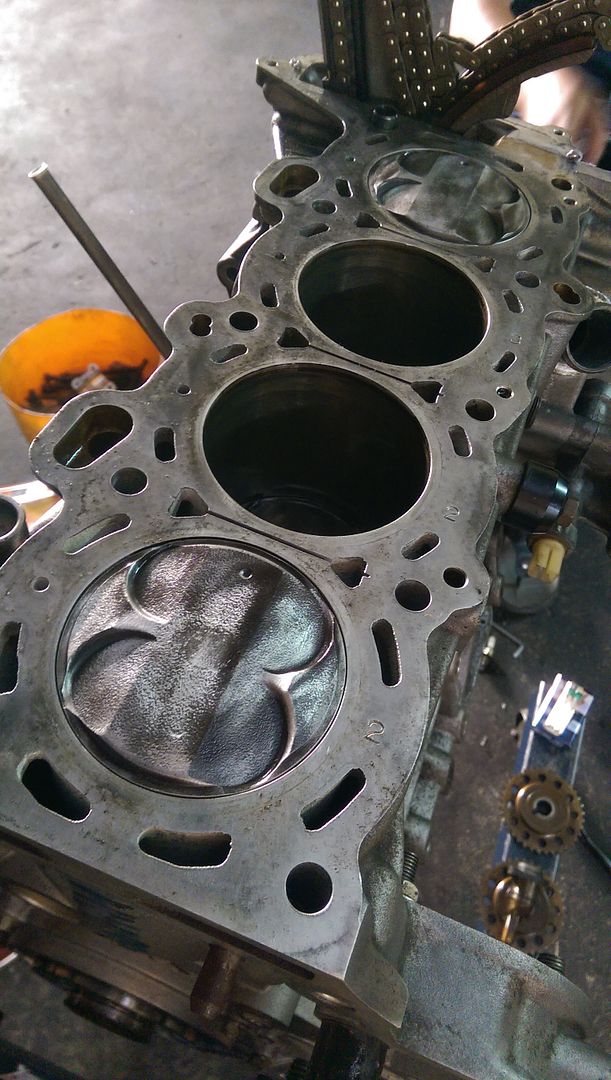

SR20VET Metal HeadGasket

SR20VE IM thermal gasket.

SR20VE Metal Exhaust Gasket.

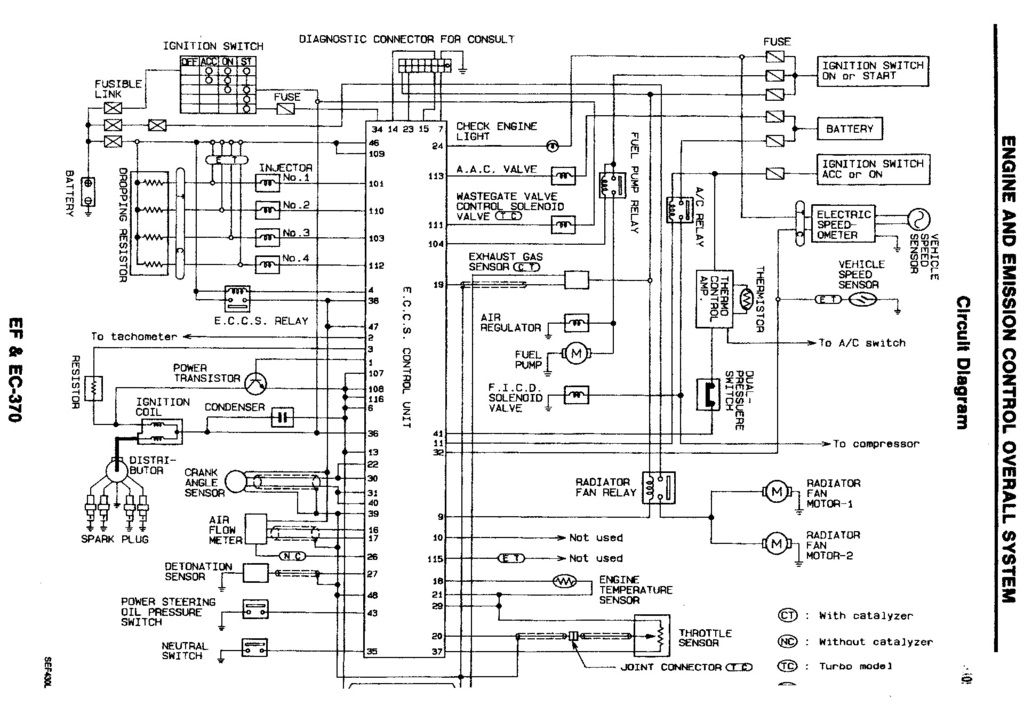

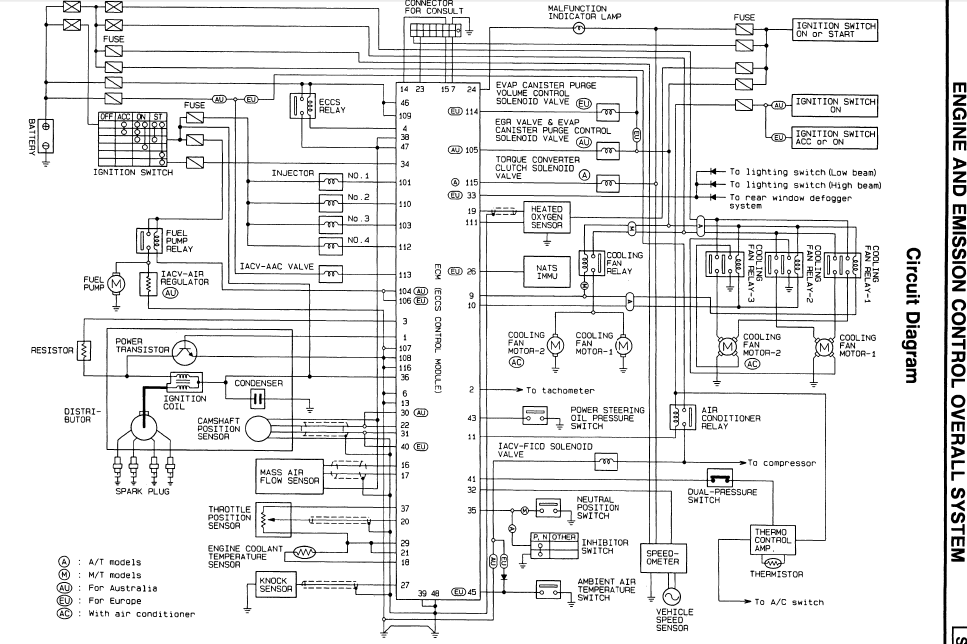

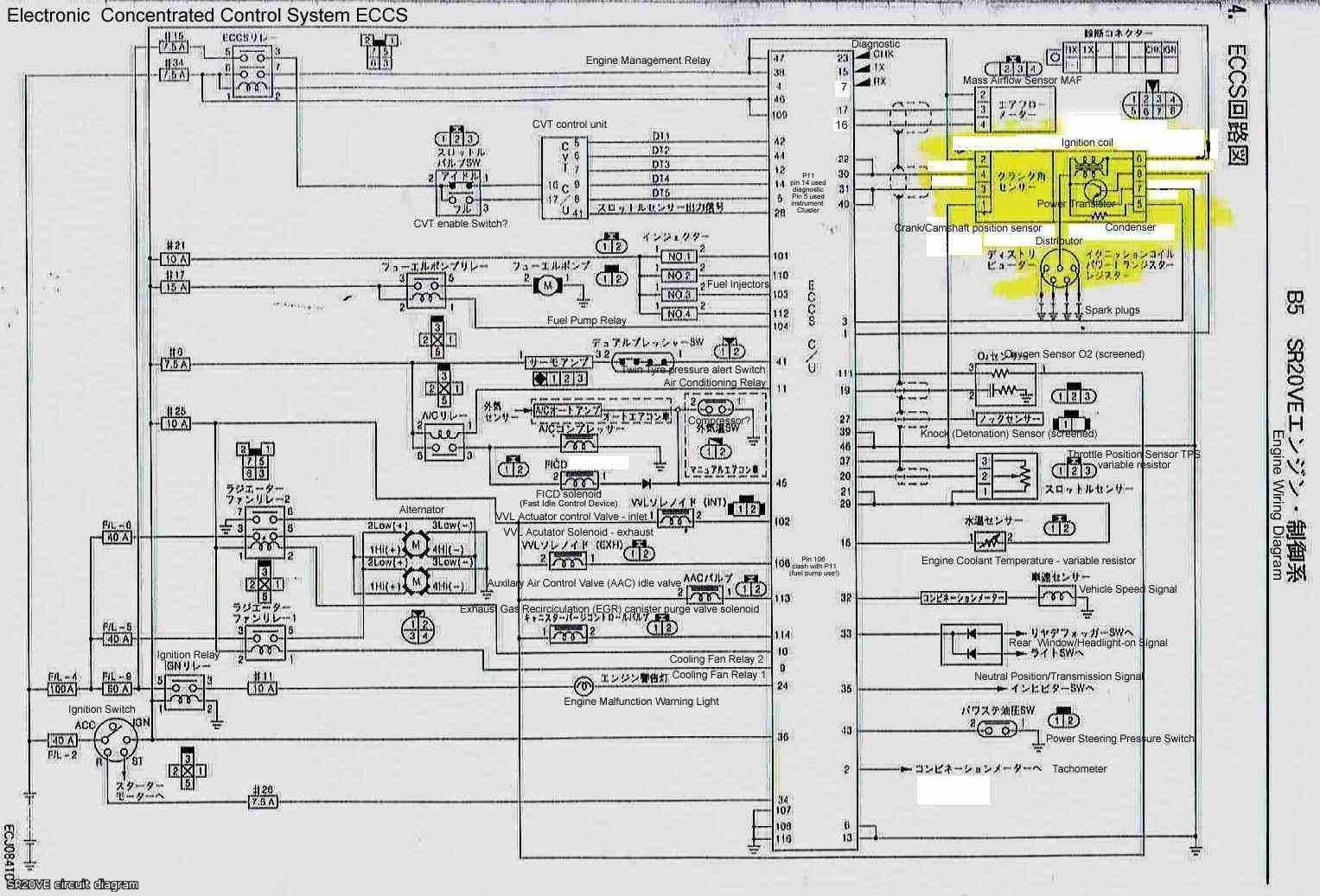

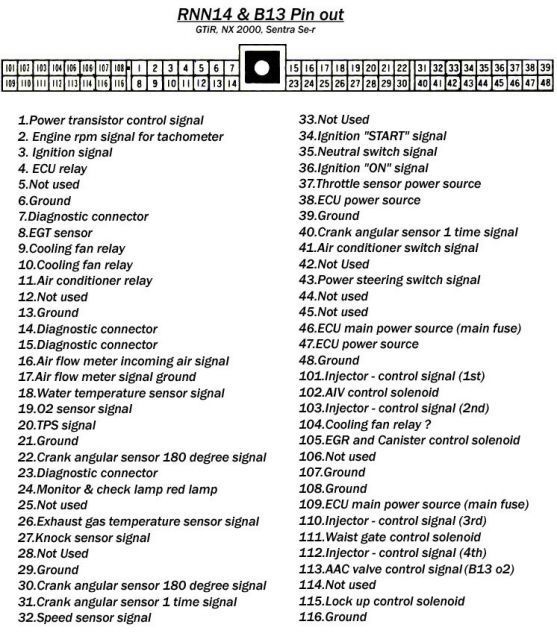

Will be using a DE dizzy (still decided if i should rewire and use a VE dizzy)

VE MAF

VE/DE rr Tbody (which ever is bigger)

To be added soon :

GTiR ECU 54C00 + Nismotronic.

370cc or S15 injectors

Locally purchased cam gears.

Only problem is designing a header. Anyone got any advise since i am pnp-ing?

Through research i got a rough idea that a 4-1 is the way, equal 22/23" long primarys 7/4" and stepped halfwayish to 15/8". Locally made 4-1 collector chocked to 2.3" and exit 2.5". The header will be made locally as well.

The is a bloke who most like will be selling off his complete N1 with TB IM. Costs a bit of money, dont now if it will be worth the investment. Research does not show significant gains with the N1 IM. (correct me if im wrong)

Goal is 200++whp onwards. Hoping to break the 160ft/lbs barrier.

Thanks Guys

Sarb

After giving it much thought, I decided I am going 20VE. Below is the build list (parts have been purchased).

COMPLETE SR20VE Engine (done 34000Kms)

N1 CAMS

SR16VE (SERIE SRV) LSD Gearbox + Flywheel

ACT 240ft/lbs Clutch Kit.

Head will be removed, and prepped (with stock valves and spring) :-

PORTnPOLISH with port match and bench flowed.

Multi angle Valve Job.

Very,very,very Mild Skimming (diamond tip)

Supertech Valve Guides and Seals (i dont think I need this since the engine is 34000kms)

SR20VET Metal HeadGasket

SR20VE IM thermal gasket.

SR20VE Metal Exhaust Gasket.

Will be using a DE dizzy (still decided if i should rewire and use a VE dizzy)

VE MAF

VE/DE rr Tbody (which ever is bigger)

To be added soon :

GTiR ECU 54C00 + Nismotronic.

370cc or S15 injectors

Locally purchased cam gears.

Only problem is designing a header. Anyone got any advise since i am pnp-ing?

Through research i got a rough idea that a 4-1 is the way, equal 22/23" long primarys 7/4" and stepped halfwayish to 15/8". Locally made 4-1 collector chocked to 2.3" and exit 2.5". The header will be made locally as well.

The is a bloke who most like will be selling off his complete N1 with TB IM. Costs a bit of money, dont now if it will be worth the investment. Research does not show significant gains with the N1 IM. (correct me if im wrong)

Goal is 200++whp onwards. Hoping to break the 160ft/lbs barrier.

Thanks Guys

Sarb

Last edited by Sarb

on 2016-02-29

at 14-38-06.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top