I would love for somebody to try it but I think the amount of work and modifications it would require, would far outweight the potential benefits.

You would have to cut the plenums on the end, to fit and you would have to modify the bottom of the plenum to allow the runners to fit/line up properly. This would be a lot of work. The other option would be to cut out the bottom part pf the plenum and make a custom bottom plate to allow the stock runners to mount up. At this point you are re-enginerring the VE plenum and it is no longer cost-effective. It would be cheaper to just make a custom plenum with off-the-shelf pieces.

The other problem with this set-up would be the requirement of two TB's, two TPS's and two MAF's. You would have to account for the extra wiring for these items. Also, I don't believe you could just splice into the existing harness as it would change the voltage outputs for each signal, with double the load. Now, you may be able to account for this with a stand-alone ECU and voltage adjustments, but I just don't know how this would work.

I would assume that a setup like this would require a stand-alone ECU and possily different sensors, i.e. getting rid of the MAF altogether and tuning with speed density? I don't know enough about how this would work (speed density).

Maybe a "tuner" could chime in on this two TB/TPS/MAF vs no MAF and speed density set-up and let us know what they think? Am I on ppoint with my theories?

I think the best bet might be a RAM air type manifold, seperated into two seperate chamber/inlets wiith dual TB's and no MAF. Very similar to the TB Motorworx setup that Nismo94tuner posted. This would keep the flow equal for both sets of cylinders, make the manifold design somewhat simple and allow for more flow to each set of cylinders (with the dual TB). The TB linkage could be shared/have shared TPS as well. The inside of the plenum would have trumpets built into the base of the plenum.

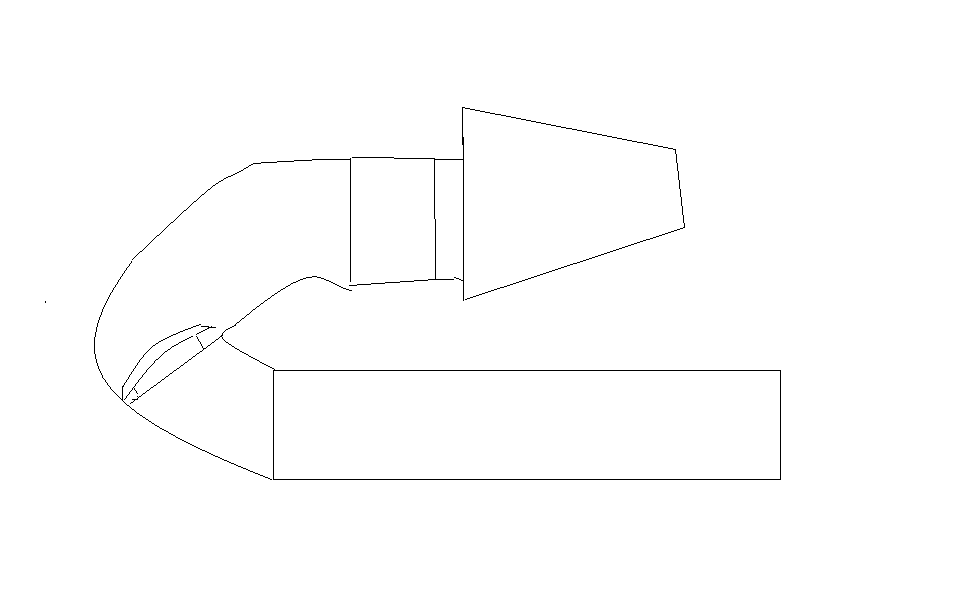

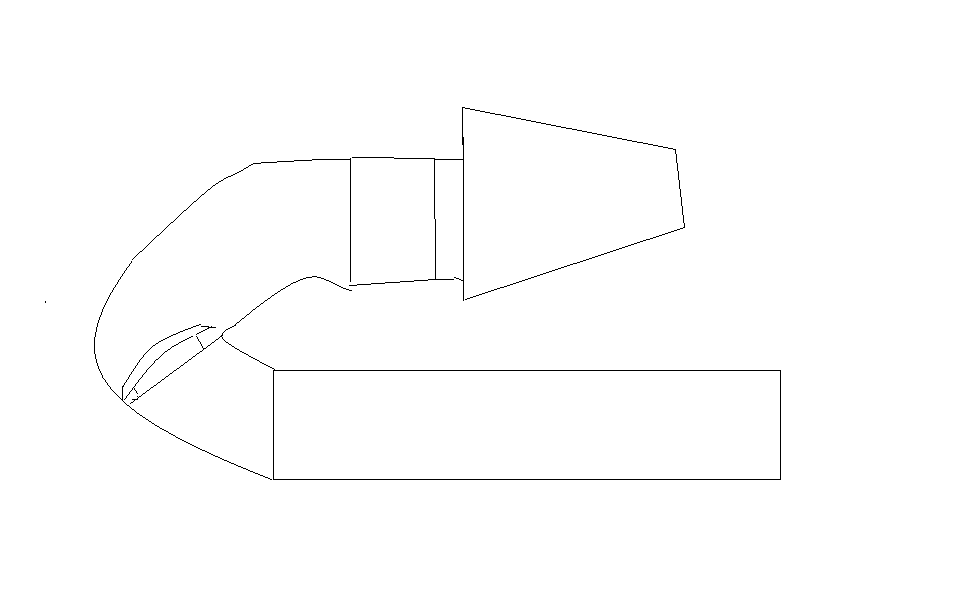

Something like this....

Side view of cylinder head with plenum/trumpets and air filter. DOn't mind the dimensions as I used paintshop. You get the idea anyway

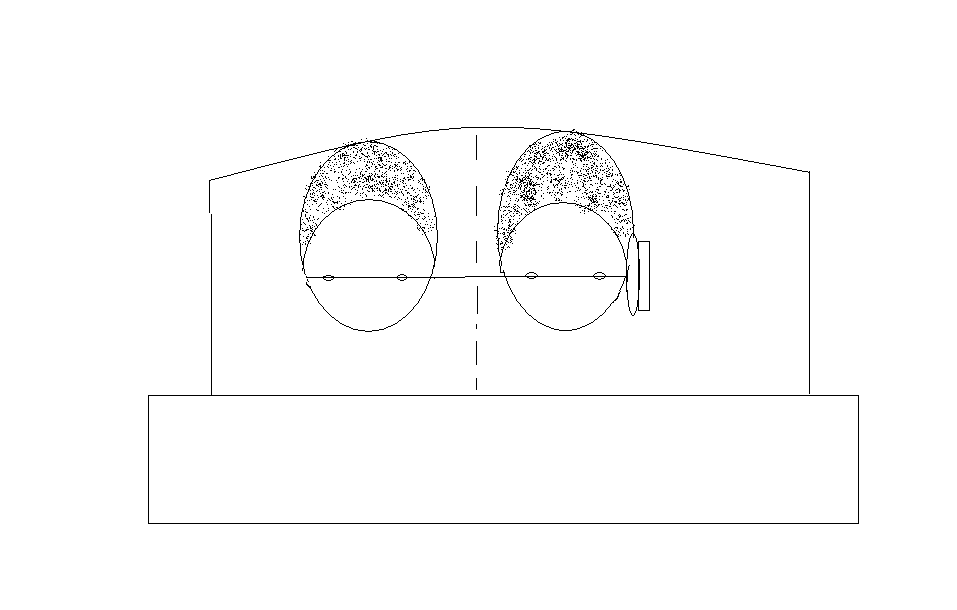

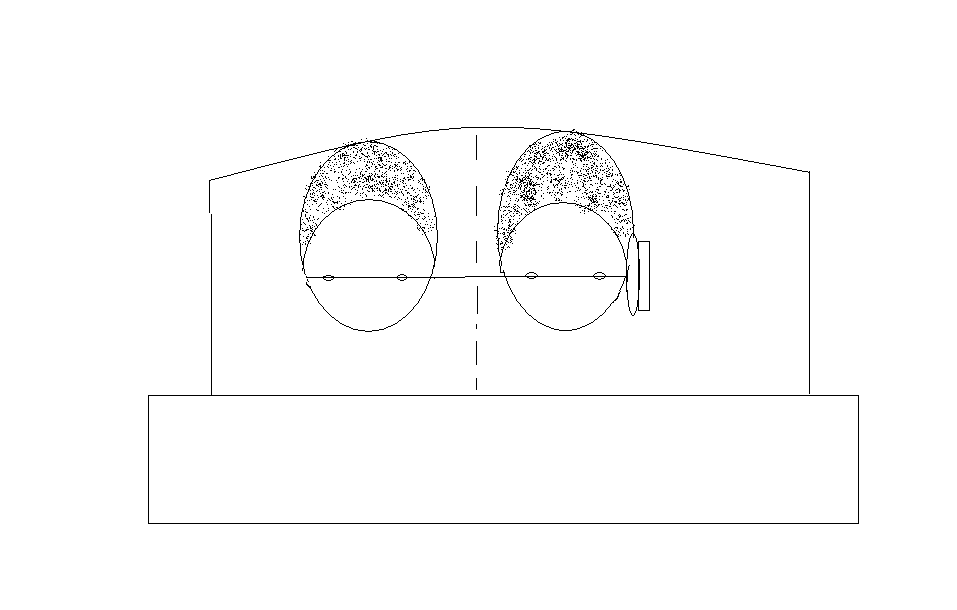

Front view of engine with split/dual runner setup with dual TB's and shared TB linkage/TPS setup. The dotted line shows the divided chamber for each set of cylinders.

Hopefully my simple drawings will be easy to understand...This would definitely be custom but would be cheaper than ITB's. You could make the bottom part of the plenum/runners the length you wanted based on your setup. The top portion would just be tubes of any length you wanted, Also, the throttle plates could be moved anywhere in the tube to account for desired throttle plate to valve head length. A set-up like this could have lots of different tuning possibilities based upon lengths and dimensions of tubing, runners, TB placement etc.

Just a thought.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Nicoxis likes this post.

Nicoxis likes this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.