Ok, so my scanner still is not working so i tried to take decent photo's of the dyno sheets. I have more i could share but i'll let you ponder about these ones first.

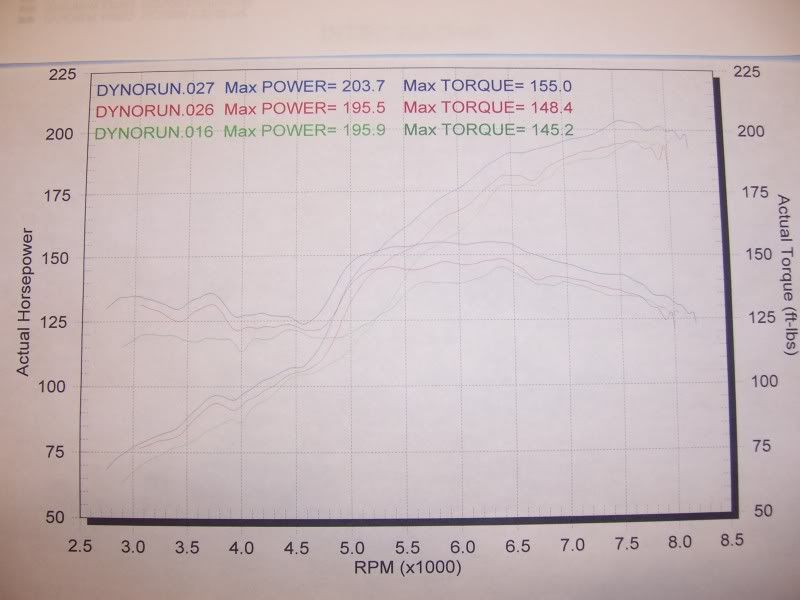

SR20DE

11.5:1 comp

Solid lifter setup/ Jun 280 cams

custom 4-1 header

Standalone

head work

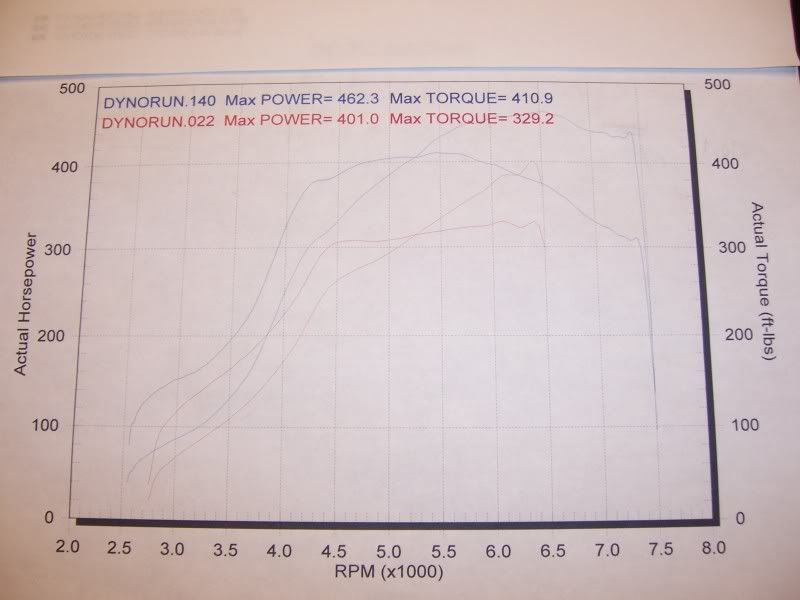

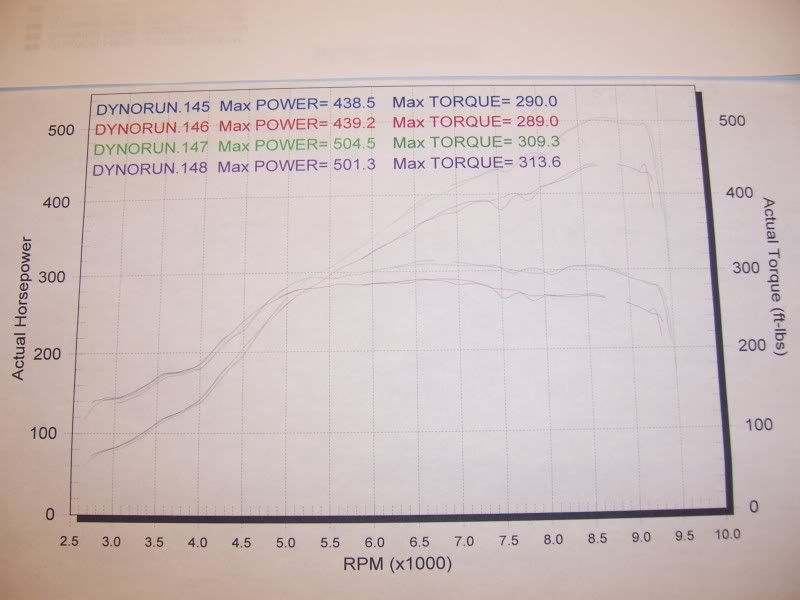

This dyno show's the usual gains in Power and powerband shift from cam gear settings. This is a big cam DE motor so the power gains in the Mid RPM range are huge from tuning the cam gears. If you notice the gains above 6500rpm are minimal by advancing the intake cam and above 7700rpm leaving the intake cam at "0" actually starts to make more power. As you can also see going to the blue line, Retarding the Exhaust cam makes power everywhere in the RPM band and about 10whp from 5000rpm+. This was actually a very good street setup.

GREEN- Cams at "0,0"

RED- Cams at "+6,0"

BLUE- Cams at "+6,-4"

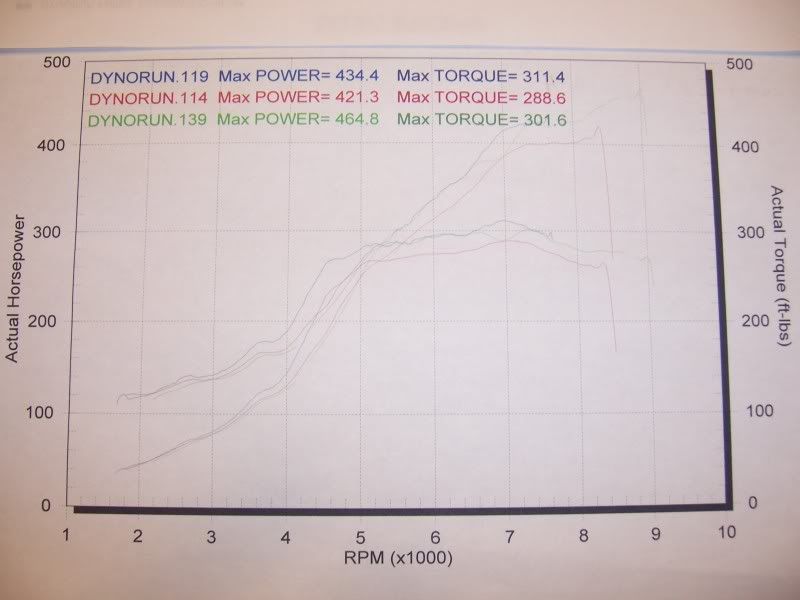

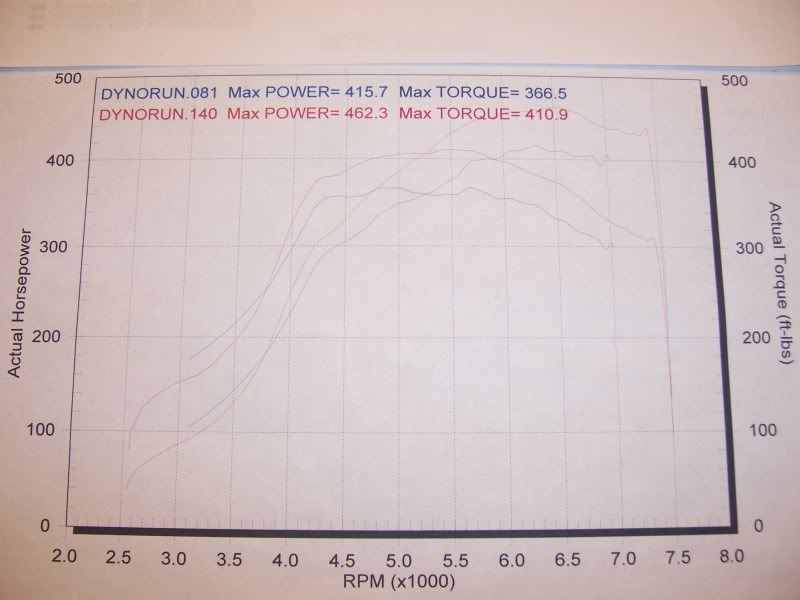

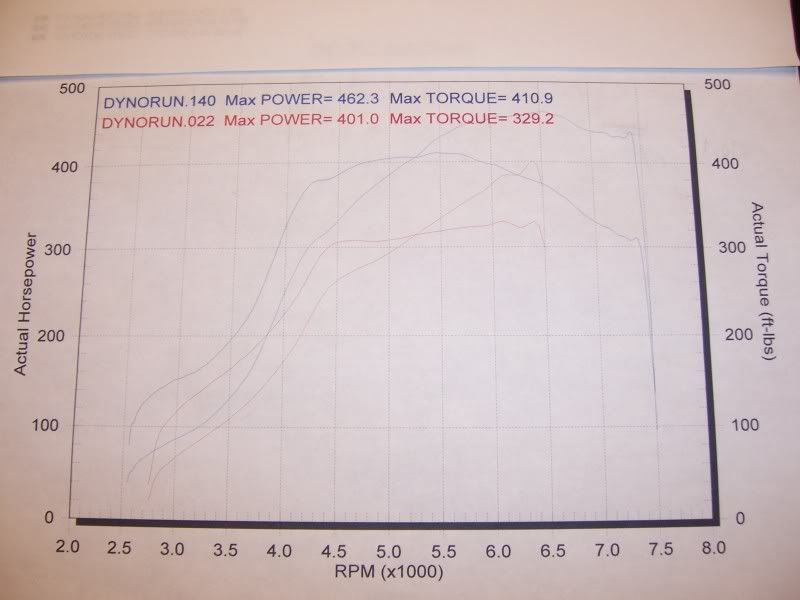

This next one is comparing a built 2.0L VET setup.

9.7:1 compression

35/30mm valves

Fully ported head

Jun springs/retainers

SR16VE cams ( std)

Cut open, fully ported N1 manifold/ T/B

T67/T4 .68 divided turbine housing, STG5 wheel

Divided turbo manifold

4" down pipe/ exhaust

Apex Power FC management

13-14psi

I have built 2 setups like this one, but this one was the better one of the 2. This motor was built 3 years ago and is still running today. This motor also was dyno'd again at another shop and had more tweaking done to it and made a little more power, about 20whp more at the same boost. This engine makes power to 10,000rpm before HP falls off. This engine was never built for super high boost, 1 bar normally and 18-20 here and there but the clutch setup could not hold the power.

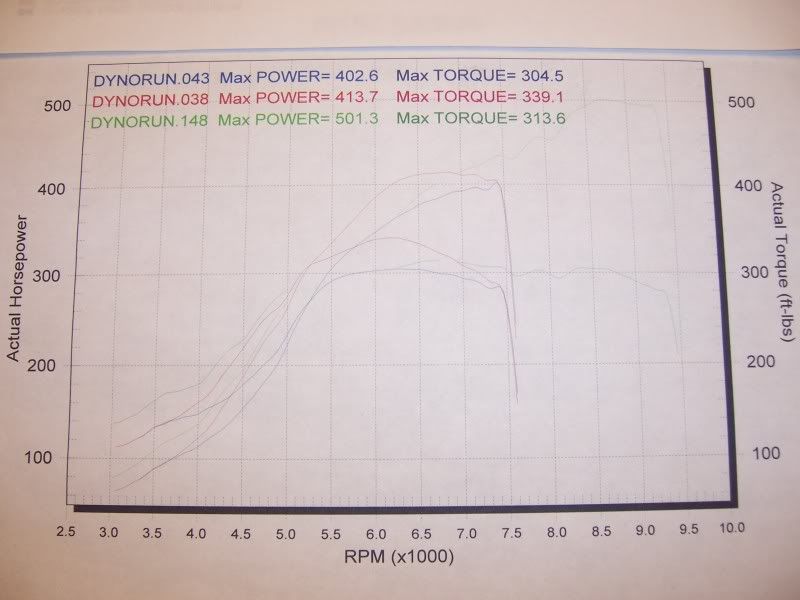

This is showing the power differences in adjusting cam gears on the dyno. As you can see the BLUE really made more power down low and actually spooled the turbo faster than any other cam gear settings. Then the RED run i went -10 on the intake cam and it lost power everywhere in boost. Now that is the one with the least amount of overlap. The GREEN run is a great run. sure it made a little less low end and spooled the turbo a little slower, but it had the best overal power band. Not shown on this sheet, the +5,0 Blue run really fell on its face at about 8000rpm and was almost 100whp behind the Green run.

BLUE- +5, 0

RED- +5, -10

GREEN- 0, -4

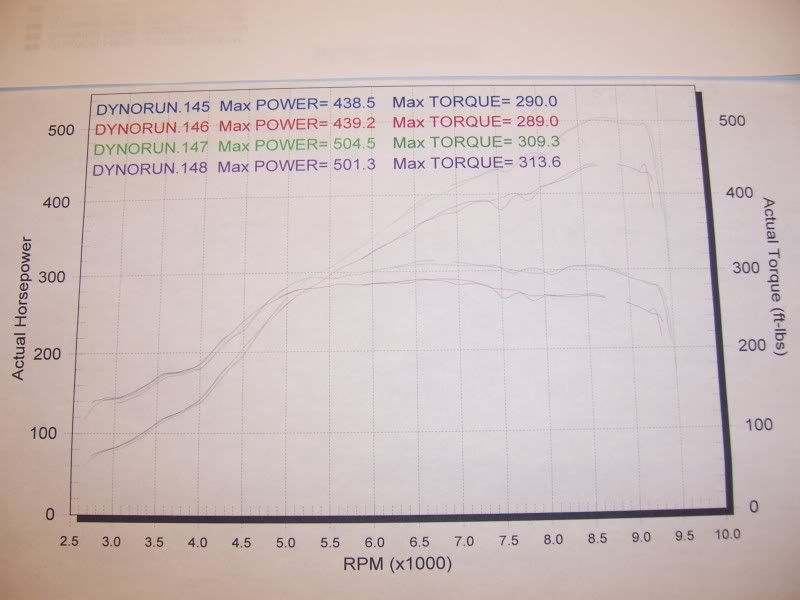

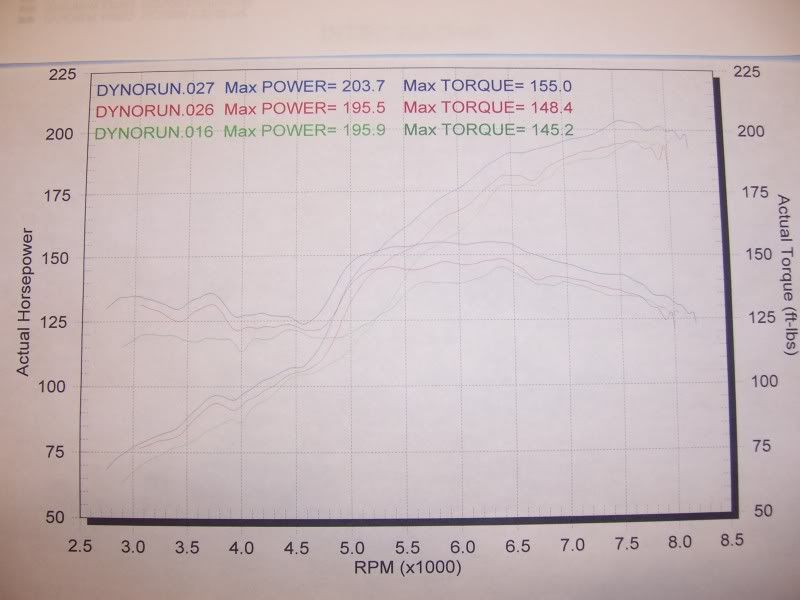

This next sheet is just a comparison between the +5, -10 runs (BLUE/RED) and the +0, -4 runs (GREEN/PURPLE)

Just overlaying 2 of each runs back to back here. as you can see the one with LESS OVERLAP MAKES THE LEAST POWER HERE and the higher you rev the engine, the greater the power difference is.

BLUE/RED +5, -10

GREEN/PURPLE +0, -4

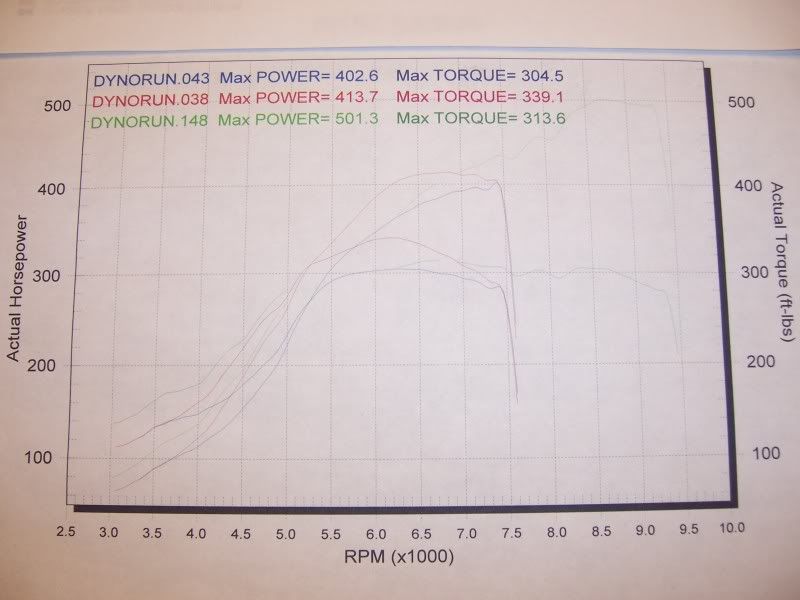

This sheet is comparing the Previous VET at 13-14 ( say 14psi) to a DET setup with a T3/T4 60-1 turbo and 2 different turbine housings. S4 cams, JWT ECU 3" exhaust Tubular manifold.

GREEN- VET setup, 14psi

RED- .63 housing, 21psi

BLUE- .82 housing, 16psi

Now here is the GT3071R turbo comparisons. I have 2 sheets to compare. I would put all 3 setups on one sheet but it gets harder to read. These are all RWD setups so the same "setup" in a FWD should yield a bit more power.

BLUE

S14 RWD DET (NVCS removed)

10:1 compression

272, 12.5mm lift cams

Ported head, stock valves

stock intake manifold, 60mm T/B

small diameter tubular divided turbo manifold

GT3071R T3 .82 divided turbine housing

FMIC 2" hotside, 2.25-2.5" cold side piping

20psi

RED

RWD S13

Greddy Intake manifold

264, 11.5mm cams

Tubular top mount

GT3071R .63 T3 turbo

20psi

As you can see the Divided housing sure can spool much much faster with the right parts. Both of these motors have had the cam gears tuned for optimal power. the Owner of the "red" dyno chart did not want his motor rev'd out any higher because he had miss shifted and broken rocker arms several times so he is scared to rev it higher. Also, to give an idea of how fast that divided housing setup spools, you can see that WOT was applied at 2600rpm.

I would really love to see this turbo setup on a VET build one day. If i had time and a car to put it in, I may actually do this one. A lower reving ( 8000rpm by lower) setup with full boost between 4000-4500rpm.

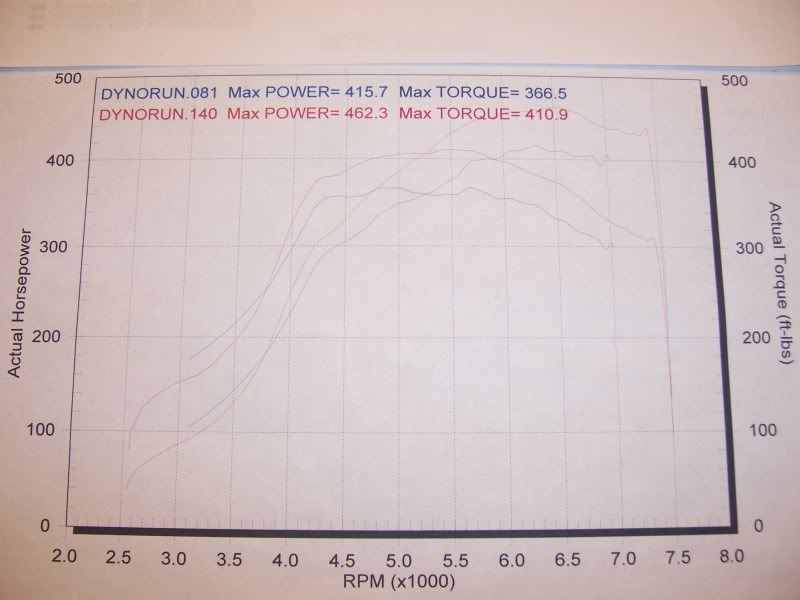

Lastly here is the same Divided GT3071R run compared to a GT3071R on the same motor a year earlier ( 2 years ago now).

RED

Same Divided setup as above

20psi

BLUE

S14 motor WITH NVCS

264 12.0mm cams

Silkroad turbo manifold

GT3071R .86

Ported head

Same FMIC setup as above

22psi

Enjoy!

-Ted

SR20DE

11.5:1 comp

Solid lifter setup/ Jun 280 cams

custom 4-1 header

Standalone

head work

This dyno show's the usual gains in Power and powerband shift from cam gear settings. This is a big cam DE motor so the power gains in the Mid RPM range are huge from tuning the cam gears. If you notice the gains above 6500rpm are minimal by advancing the intake cam and above 7700rpm leaving the intake cam at "0" actually starts to make more power. As you can also see going to the blue line, Retarding the Exhaust cam makes power everywhere in the RPM band and about 10whp from 5000rpm+. This was actually a very good street setup.

GREEN- Cams at "0,0"

RED- Cams at "+6,0"

BLUE- Cams at "+6,-4"

This next one is comparing a built 2.0L VET setup.

9.7:1 compression

35/30mm valves

Fully ported head

Jun springs/retainers

SR16VE cams ( std)

Cut open, fully ported N1 manifold/ T/B

T67/T4 .68 divided turbine housing, STG5 wheel

Divided turbo manifold

4" down pipe/ exhaust

Apex Power FC management

13-14psi

I have built 2 setups like this one, but this one was the better one of the 2. This motor was built 3 years ago and is still running today. This motor also was dyno'd again at another shop and had more tweaking done to it and made a little more power, about 20whp more at the same boost. This engine makes power to 10,000rpm before HP falls off. This engine was never built for super high boost, 1 bar normally and 18-20 here and there but the clutch setup could not hold the power.

This is showing the power differences in adjusting cam gears on the dyno. As you can see the BLUE really made more power down low and actually spooled the turbo faster than any other cam gear settings. Then the RED run i went -10 on the intake cam and it lost power everywhere in boost. Now that is the one with the least amount of overlap. The GREEN run is a great run. sure it made a little less low end and spooled the turbo a little slower, but it had the best overal power band. Not shown on this sheet, the +5,0 Blue run really fell on its face at about 8000rpm and was almost 100whp behind the Green run.

BLUE- +5, 0

RED- +5, -10

GREEN- 0, -4

This next sheet is just a comparison between the +5, -10 runs (BLUE/RED) and the +0, -4 runs (GREEN/PURPLE)

Just overlaying 2 of each runs back to back here. as you can see the one with LESS OVERLAP MAKES THE LEAST POWER HERE and the higher you rev the engine, the greater the power difference is.

BLUE/RED +5, -10

GREEN/PURPLE +0, -4

This sheet is comparing the Previous VET at 13-14 ( say 14psi) to a DET setup with a T3/T4 60-1 turbo and 2 different turbine housings. S4 cams, JWT ECU 3" exhaust Tubular manifold.

GREEN- VET setup, 14psi

RED- .63 housing, 21psi

BLUE- .82 housing, 16psi

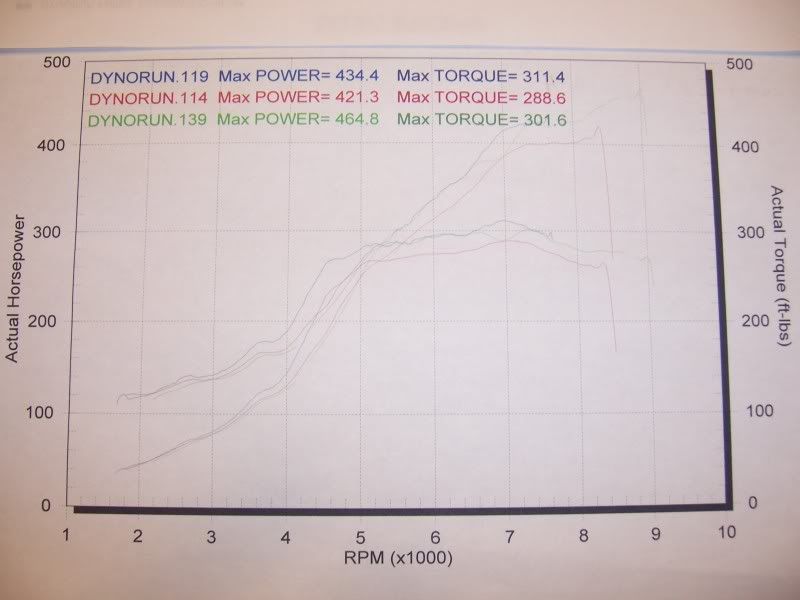

Now here is the GT3071R turbo comparisons. I have 2 sheets to compare. I would put all 3 setups on one sheet but it gets harder to read. These are all RWD setups so the same "setup" in a FWD should yield a bit more power.

BLUE

S14 RWD DET (NVCS removed)

10:1 compression

272, 12.5mm lift cams

Ported head, stock valves

stock intake manifold, 60mm T/B

small diameter tubular divided turbo manifold

GT3071R T3 .82 divided turbine housing

FMIC 2" hotside, 2.25-2.5" cold side piping

20psi

RED

RWD S13

Greddy Intake manifold

264, 11.5mm cams

Tubular top mount

GT3071R .63 T3 turbo

20psi

As you can see the Divided housing sure can spool much much faster with the right parts. Both of these motors have had the cam gears tuned for optimal power. the Owner of the "red" dyno chart did not want his motor rev'd out any higher because he had miss shifted and broken rocker arms several times so he is scared to rev it higher. Also, to give an idea of how fast that divided housing setup spools, you can see that WOT was applied at 2600rpm.

I would really love to see this turbo setup on a VET build one day. If i had time and a car to put it in, I may actually do this one. A lower reving ( 8000rpm by lower) setup with full boost between 4000-4500rpm.

Lastly here is the same Divided GT3071R run compared to a GT3071R on the same motor a year earlier ( 2 years ago now).

RED

Same Divided setup as above

20psi

BLUE

S14 motor WITH NVCS

264 12.0mm cams

Silkroad turbo manifold

GT3071R .86

Ported head

Same FMIC setup as above

22psi

Enjoy!

-Ted

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top