With another Mt. Washington hillclimb coming up, my friend Tim Mather's '91 Sentra needed a few tweaks done to it to make it a more enjoyable experience than the 2011 event. The biggest issues (aside from no power!) are limited rear tire clearance. The car ran 225/45-15 Hoosiers last time around, on 15 x 7 Kosei wheels. Trouble is they rubbed like crazy out back, both inboard and outboard.

I addressed the inboard clearance issue by building some new rear struts. His old Leda's were leaking like crazy anyway, so I made some aluminum-bodied struts with Koni B15 front inserts. We used short 7" springs and some flat wire Hyperco helper springs, plus I made the strut mounting ears longer to move the strut body inboard. Problem one solved.

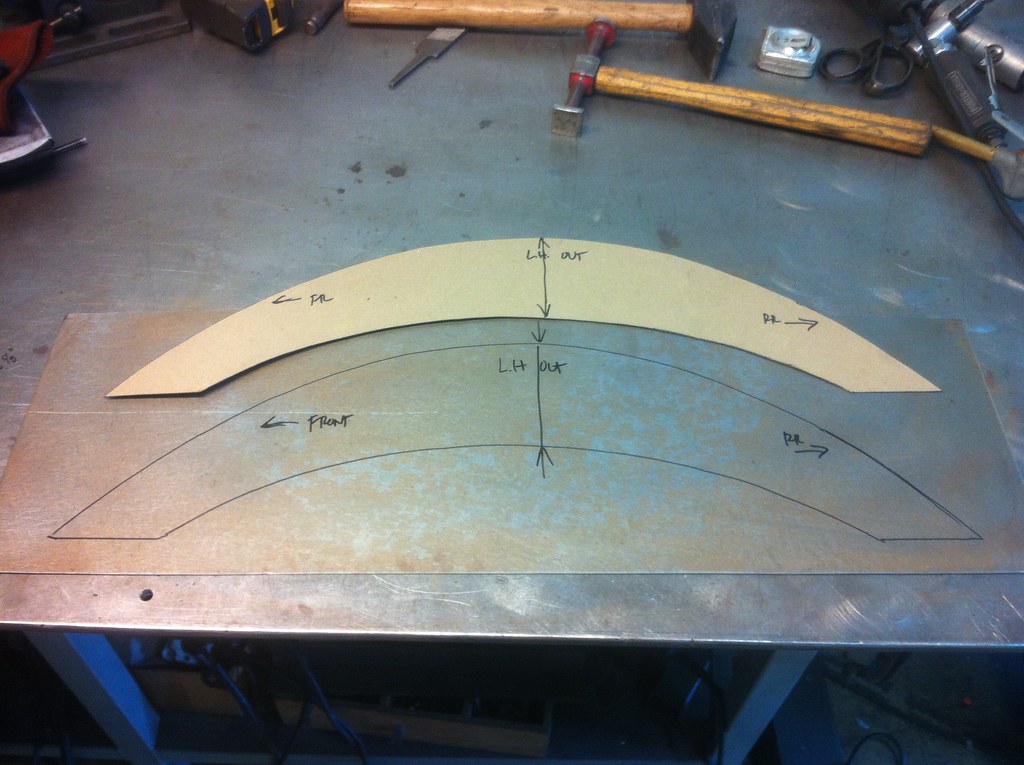

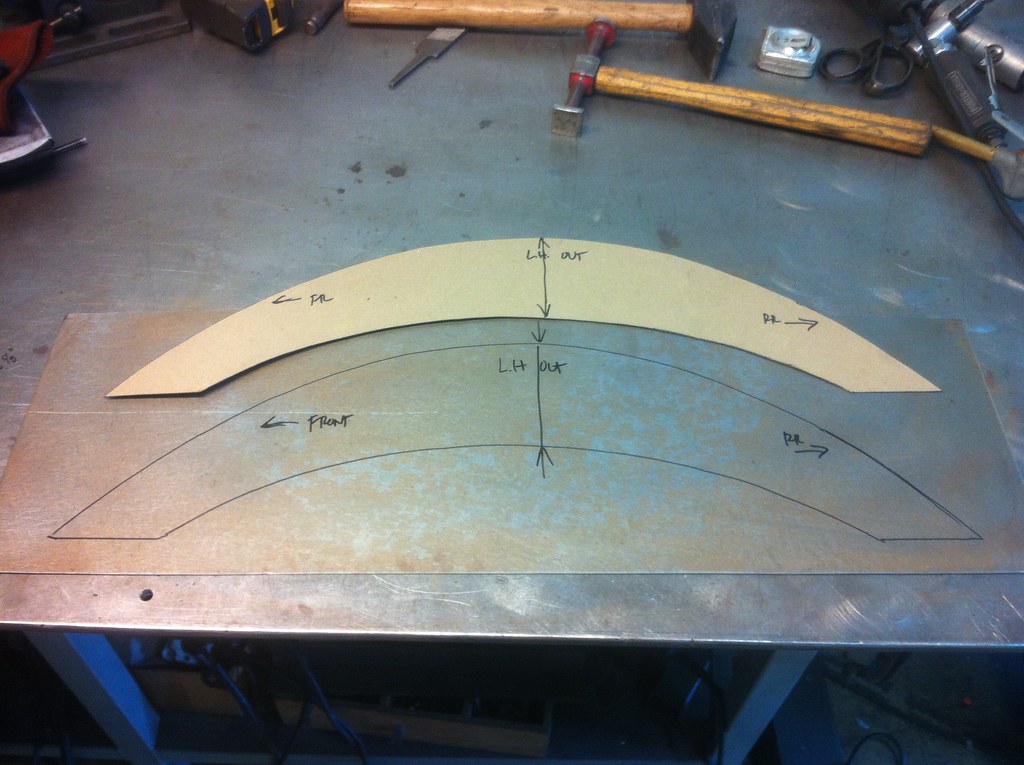

For the outboard clearance, the car needed fender flares. The original inner wheelwells were hammered to the outer skin, and the edges were rolled. No good, they still hit badly. So I fabricated a pair of sheetmetal flares from some 22 gauge steel. I roughed out a template from cardboard, then transfered that to the metal. I used a plastic round-faced hammer and a shot-bag and stretched the flat metal into the general shape I wanted. This was followed by a few passes thru an English wheel to smooth the hammer marks out.

Once I got to this point, the wheel flare edge had to be rolled for strength, appearance, and to avoid cutting into the tires. I "turned" the edge initially on a straight T-dolly, but the final 180° rolled edge was made with a custom radiused t-dolly I made for this specific purpose. Then the final edges of the flares were trimmed to match the original cardboard template.

The last step was fitting the flares to the car. It took about 2 hours to make both flares but about 10 hours to fit them and weld them to the car. This included opening up the inner wheelwell and stretching/welding it to meet the new outer flare. This retains unibody strength, keeps the car watertight, and improves tire clearance. All in all it looks almost factory...nothing too radical, but I gained about 3/8" inner tire clearance, and about 1-1/2" outer tire clearance. We might even try to fit 15 x 9 wheels with the same 225/45-15 tires!

I addressed the inboard clearance issue by building some new rear struts. His old Leda's were leaking like crazy anyway, so I made some aluminum-bodied struts with Koni B15 front inserts. We used short 7" springs and some flat wire Hyperco helper springs, plus I made the strut mounting ears longer to move the strut body inboard. Problem one solved.

For the outboard clearance, the car needed fender flares. The original inner wheelwells were hammered to the outer skin, and the edges were rolled. No good, they still hit badly. So I fabricated a pair of sheetmetal flares from some 22 gauge steel. I roughed out a template from cardboard, then transfered that to the metal. I used a plastic round-faced hammer and a shot-bag and stretched the flat metal into the general shape I wanted. This was followed by a few passes thru an English wheel to smooth the hammer marks out.

Once I got to this point, the wheel flare edge had to be rolled for strength, appearance, and to avoid cutting into the tires. I "turned" the edge initially on a straight T-dolly, but the final 180° rolled edge was made with a custom radiused t-dolly I made for this specific purpose. Then the final edges of the flares were trimmed to match the original cardboard template.

The last step was fitting the flares to the car. It took about 2 hours to make both flares but about 10 hours to fit them and weld them to the car. This included opening up the inner wheelwell and stretching/welding it to meet the new outer flare. This retains unibody strength, keeps the car watertight, and improves tire clearance. All in all it looks almost factory...nothing too radical, but I gained about 3/8" inner tire clearance, and about 1-1/2" outer tire clearance. We might even try to fit 15 x 9 wheels with the same 225/45-15 tires!

Back to top

Back to top