also I don't know if you mentioned it before but what tig setup are you running?

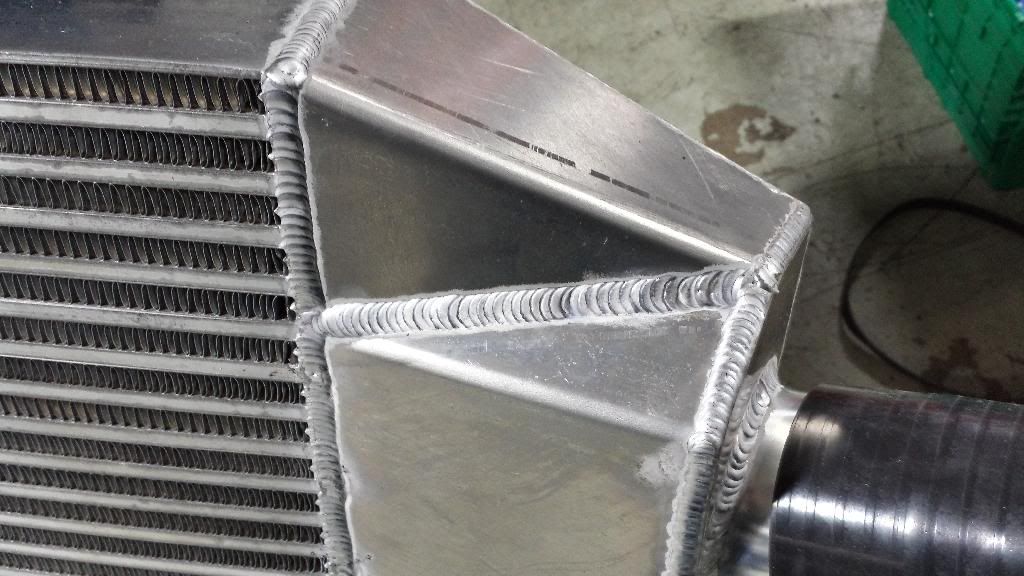

I'm using the AHP alpha tig 200. I put a gas lens setup on and a #8 cup on the torch. Should I use a bigger cup?

nice!

you deff can run a bigger cup if you want. typically bigger the better when It comes to stainless.

I use this kit at the moment, it has a very large clear cup pyrex over 1" big. it works fairly well.

Deluxe Gas Saver Pro Kit? For: 2, 9, 20 & CS310 Torches [CK-D2GS-PRO-DX] - $215.00 : Arc-Zone.com, The Welding Accessory Experts

but am going to be trying out another setup soon.

Monster? Nozzle Pro Kit, For 17/18/26 & 3-Series TIG Torches [AK-MNK-1726-Pro] - $103.22 : Arc-Zone.com, The Welding Accessory Experts

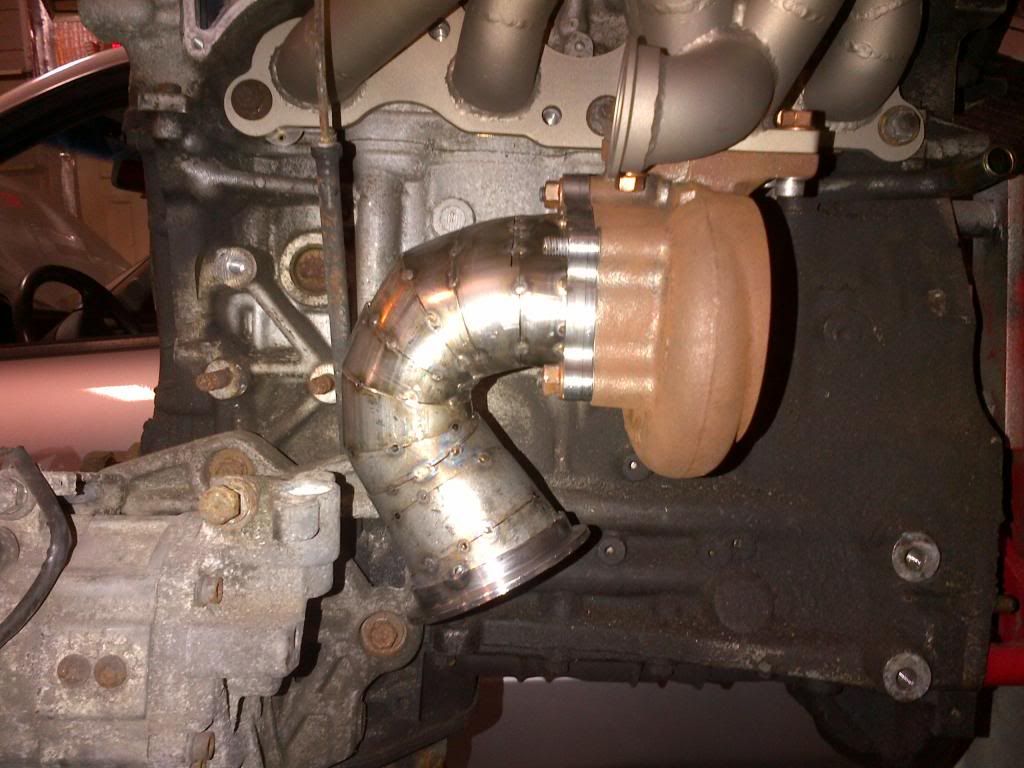

once you get your welds down good. you will have to try backpurge. it is night and day how good ss welds when purged correctly

Back to top

Back to top