Today while I was doing a boost leak test, I noticed how badly the VE/RR PCV valve was leaking. Replaced it with another one I had which had low miles, still leaking, much less though. Tested a DE one that I had before, leaking as much as the newer VE one, which I would equate to having a paperclip sized hole in one of the silicon couplers. It's a big enough leak to mess with the max boost on a small turbo and overpressure the crankcase (I was down 1.5 psi at redline on a t25 just from going to VE valve cover from DET one).

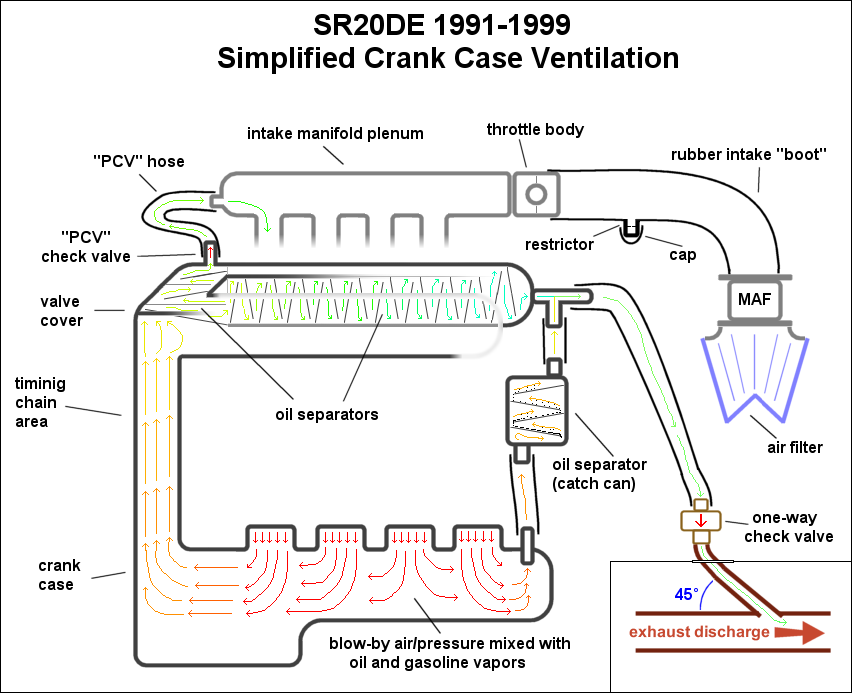

At first I thought about making another inline check valve with ball and spring, just like manual boost controller is. But then I reconsidered the traditional PCV system altogether. Why not just add it to the valve cover breather, then send it to the valve cover breather, which eventually will go to turbo intake. With this configuration there should be a constant vacuum provided to the PCV valve, especially in boost. This should help reduce the crankcase pressure, not by much but it will definitely stop adding on to it due to leaky OEM PCV valves!

Better route would be to use an oil catch can of course.

I for the life of me could not get this to work on my turbo VE, gave up on trying, not enough room to find a good spot for it either.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. BenFenner likes this post.

BenFenner likes this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.