Welcome back from reading the

naturally aspirated version of the crank case ventilation system. You did read the

naturally aspirated edition, right?

Yes?

Okay good.

The main difference between a boosted engine and a naturally aspirated engine for these discussions is that in a boosted application the intake tract can be pressurized above atmospheric pressure. This means that where you used to have zero net pressure, you will have some positive pressure in the intake system. This changes the options of where you can vent the crank case to. You'll want to find new sources of vacuum, and you'll want to make sure you don't accidentally let boost pressure enter the crank case and pressurize it.

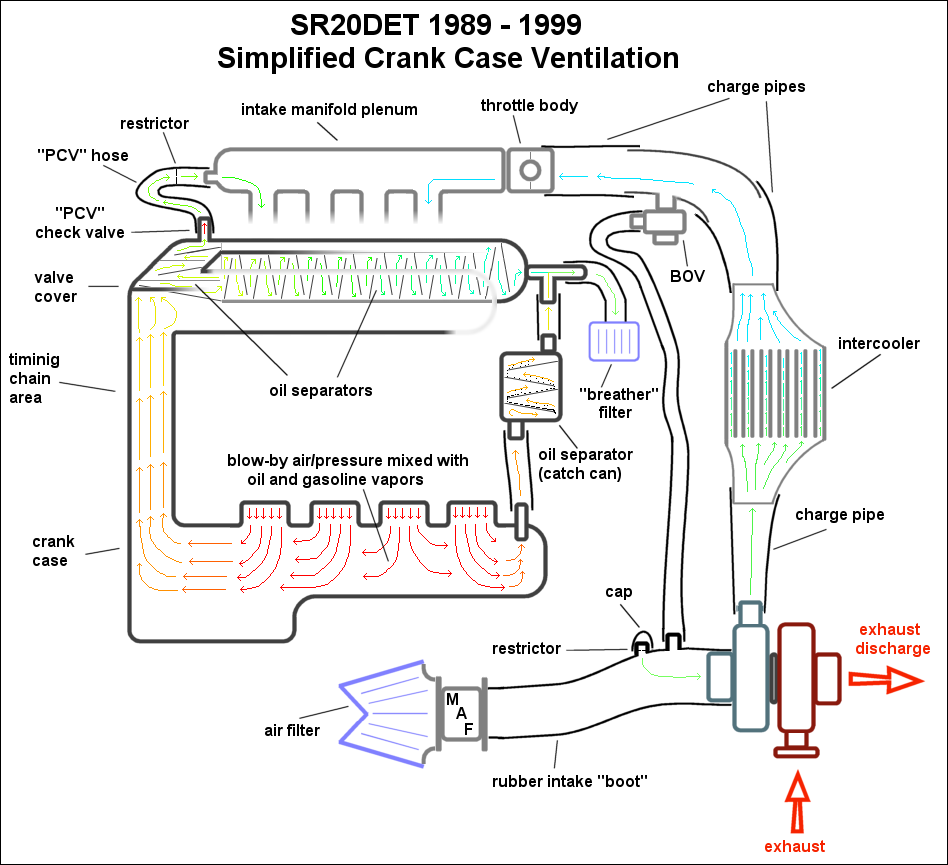

Another important factor with most turbocharged engines regarding crank case ventilation involves the intercooler. If the blow-by gasses are routed through the intercooler, the intercooler then in effect gets to act as a giant oil separator. Oil tends to coat the inside of the intercooler decreasing its thermal efficiency. The oil can also build up and puddle, drain into unwanted places, or be consumed by the engine in larger quantities at inopportune times. For this reason, you will see some of the modifications listed in the "BAD" section of the

Naturally Aspirated edition (that made little-to-no sense at all on an N/A engine) all of a sudden become acceptable solutions on a turbocharged engine.

There is

one more difference between N/A and boosted engines that you should be aware of.

Boosted engines tend to have much higher cylinder pressures than naturally aspirated engines. This produces more power obviously, but it also produces more "blow-by" which you will recall from the

naturally aspirated edition of this topic is something we'd like to limit and control.

And don't forget what you learned in the naturally aspirated edition about blow-by gasses increasing your chances of detonation.

Originally Posted by

BenFenner  How does blow-by lower your octane? Blow-by gasses with any amount of oil in them will lower the effective octane rating of your fuel because the vaporized oil will ignite at lower energy levels than 87 octane (R+M/2) gasoline. The more of it you allow to enter the cylinder, the more you will have to worry about detonation. This is usually not a big worry for naturally aspirated engines, but obviously forced induction is a different story.

How does blow-by lower your octane? Blow-by gasses with any amount of oil in them will lower the effective octane rating of your fuel because the vaporized oil will ignite at lower energy levels than 87 octane (R+M/2) gasoline. The more of it you allow to enter the cylinder, the more you will have to worry about detonation. This is usually not a big worry for naturally aspirated engines, but obviously forced induction is a different story.

These three things conspire to make ventilating the crankcase of a turbocharged (or supercharged) engine more difficult and more important than on a naturally aspirated engine. Most people don't even bother messing with the crankcase ventilation system on naturally aspirated engines and only wait until they turbocharge the engine to get serious about the system, because now the ante has been raised.

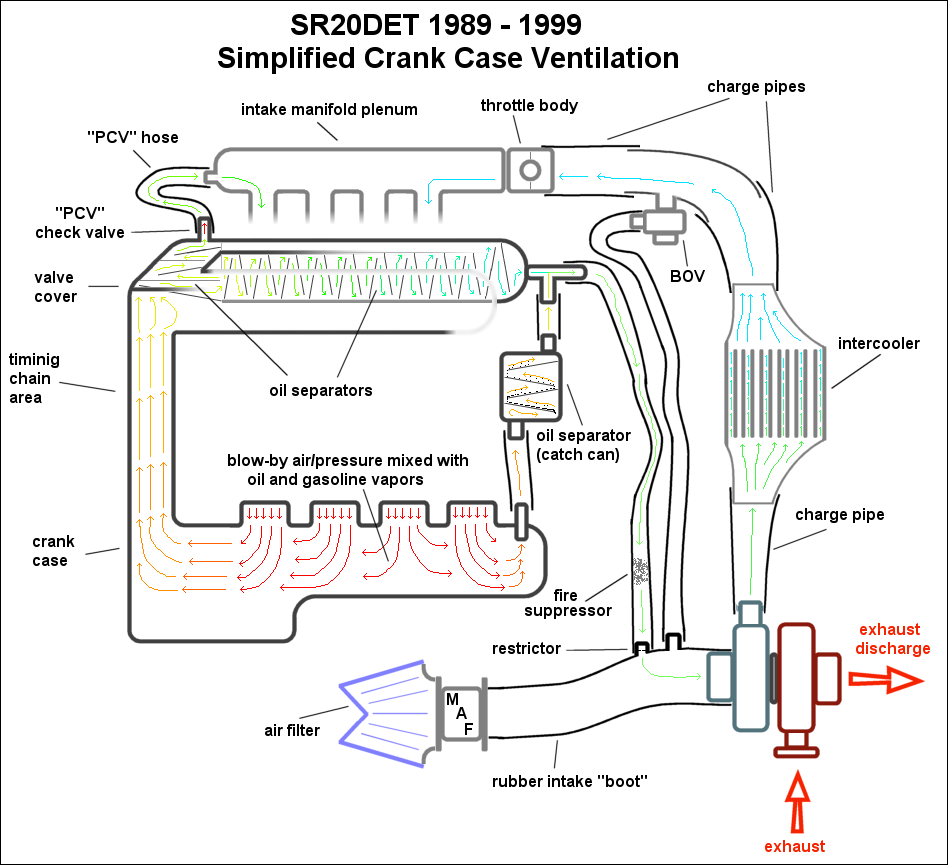

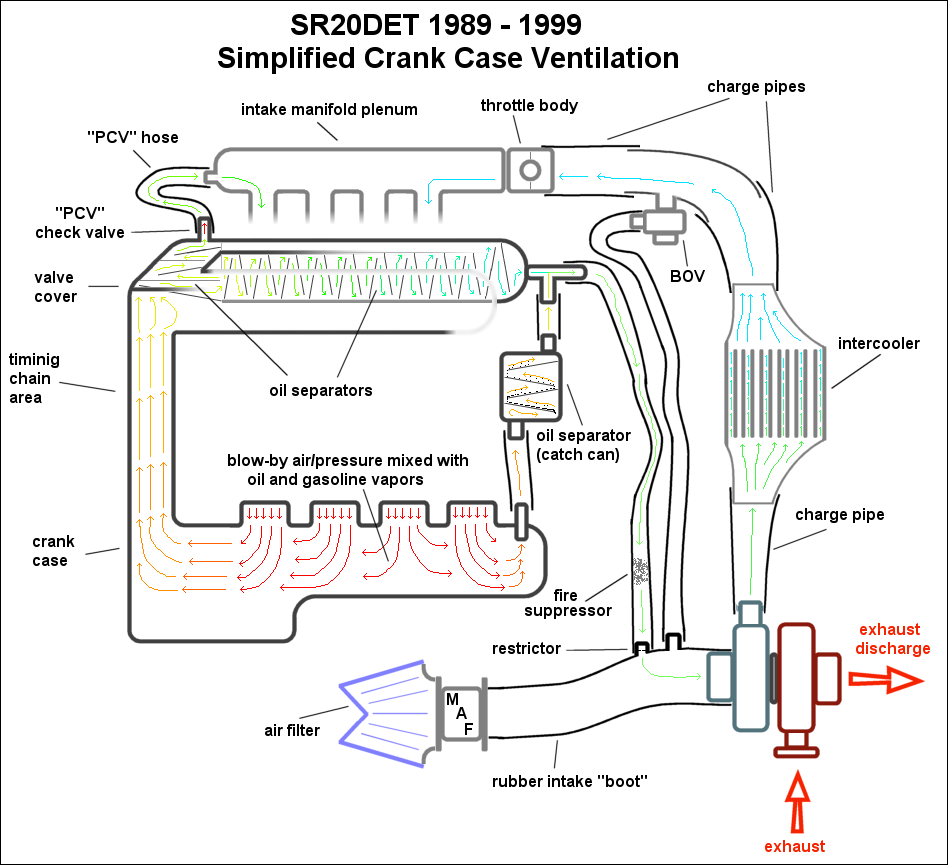

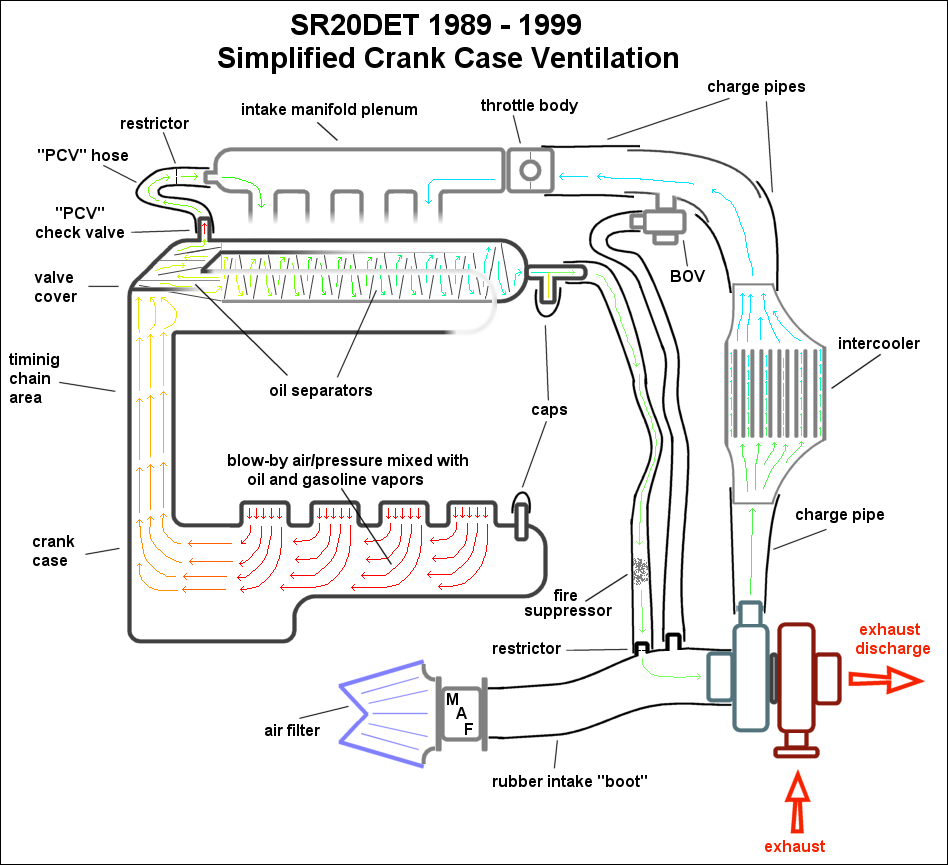

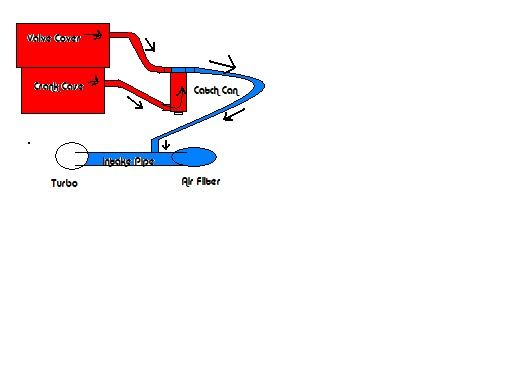

We should start off with a diagram of the factory positive crankcase ventilation system as seen on most common SR20DET engines.

You should first notice one key difference between this setup and that of the naturally aspirated engines. In this setup, the ventilation pathway for the engine blow-by during WOT conditions no longer connects to the intake tract right before the throttle body. The connection is now made before (upstream) of the turbocharger but ahead (downstream) of the MAF. If you think about it for a moment, it makes a lot of sense because the old connection point would just pump pressurized intake charge air into the crank case when the engine is "in boost" which is a really bad idea. The designers had to find a new place to vent the crank case and yet maintain emissions compliance. Venting the crankcase to the intake tract before the turbo is basically identical to venting it to the intake on the naturally aspirated engines. There isn't really much vacuum there during WOT or ever, but there is a slight vacuum and the blow-by gasses get consumed by the engine and the EPA is happy.

Also mentioned before and extremely important to understand is the fact that the ventilation of the crankcase dumps into the intake tract upstream (after) the MAF sensor. This is to prevent any oily blow-by gasses from quickly contaminating and/or ruining the MAF sensor. I'm not going to get into the pros and cons of moving the MAF sensor to the pressure side of the intake tract right now, but suffice it to say, you need to avoid recirculating blow-by emissions coming into contact with the MAF element. (Cars equipped with a MAP sensor as the primary air metering device can ignore this warning.)

It should be said that the factory setup is a very good solution. It is pretty difficult to improve on it, and it is EXTREMELY easy to make it worse. Keep that in mind when considering "upgrades".

Okay. On to the different methods of improving, or completely messing up the factory crank case ventilation system. These methods will cover a huge mix of things I've seen done on people's cars, or that I thought up in my head. Some will be great ideas, some will be good ideas, some will be bad ideas, and some will be awful ideas. I'm going to keep things simple by rating each method on the important points so you can just give it a quick look and see immediately if it's a good idea or not.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top