I don't see that he mentioned it so I will..

it will start cold if you spray a little starting fluid in it. It will also start if you wedge the tps tab open (leaving to closed)

It may start up rough but better than not at all, at least it gives us a direction to look which has been making me thinking enough fuel..

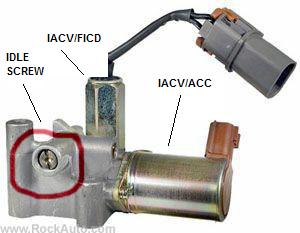

I'm not confident that was conclusive, I need to retry on a colder day. It didn't start on the first try every time either methods. Colder it is the more attempts it takes so I need to try those on a colder night/morning to really know. I have an IACV and AaC inbound so I'll be able to rule those out this weekend. Then I'll focus on fuel, but if injector resistance is good, not leaking and pump holds/delivers correct pressure, what am I looking at? (an ecu is good)

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top