From

excellent thread by Resolute on my350z.com Please note this is entirely his work and I take no credit whatsoever for all the time and effort he's put in documenting this info

Strongly encourage people to check out the entire post by Resolute, here's his great overview on UOA and Oil in general:

How do I read the attached UOA Comparison Charts?

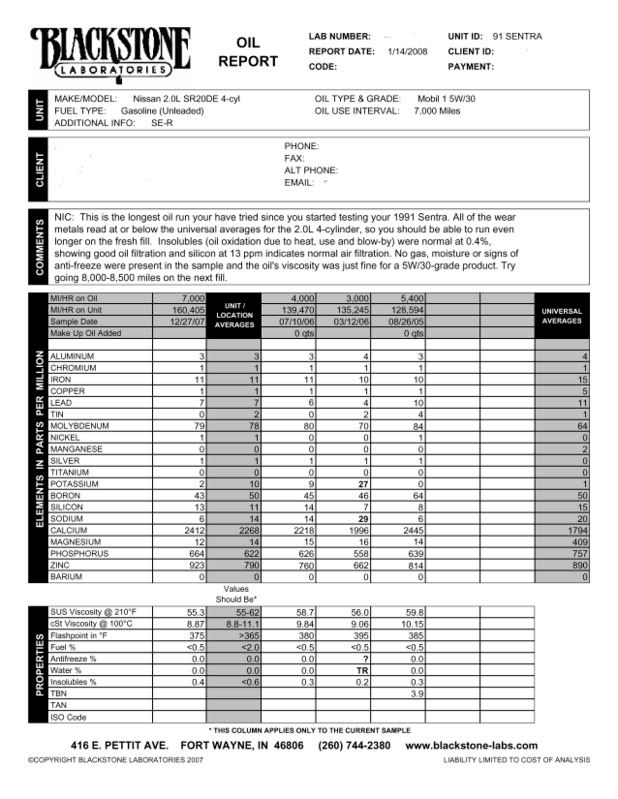

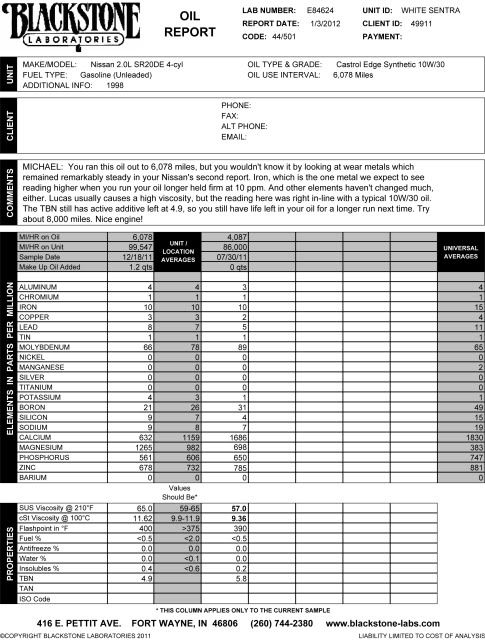

The name and weight of each oil tested is at the top of the comparison charts. The column below it shows the average mileage on that particular oil, followed by any amount of make-up oil added during the average oil change interval. This is important to look at when comparing oils, as an oil that has just 1,000 miles on it when tested will obviously fare better than an oil that has 9,000 miles on it when tested, even if it is not really a better performing oil. The next part (The Grey Section) of the column contains the elements found in the used oil, measured in parts per million (ppm). This reflects the type and amount of metals that were worn off of engine parts. Lower levels of metals are better. The bottom of the column (The Red Section) shows the oil viscosity and TBN of the oil after use.

Where exactly do the traces of metals come from, and how do they indicate engine wear?

The most common metals in your used oil and where they come from are listed below. These metals come off of different parts of your engine during operation. Your oil protects the surfaces of your engine from wear, but some oils do a better job of others. Oils that have low numbers of these metals did a good job of protecting the engine’s surfaces from wearing down with use. So look for an oil that shows low numbers of these elements:

Iron: Comes from cylinder liner, camshaft, oil pump, and timing chain wear

Chromium: Comes from piston ring wear

Copper: Comes from bearings, valve guides, and bushings wear

Lead: Comes from bearing wear

Aluminum: Comes from piston and piston thrust bearing wear

Silver & Tin: Comes from bearing wear

Which metals are the most important to have low numbers?

I look for the lowest possible numbers of Lead, Copper, and Chromium in the oil sample to indicate better protection of critical areas. The bearings and piston rings are not just critical areas because of their function, they are critical to protect because they comprise a much smaller amount of the total engine mass than Iron and Aluminum parts. 5ppm wear of Lead off a relatively tiny bearing is a much higher percentage of wear than 5ppm of Iron would be from all the Iron found in the crankshaft, camshafts, timing chain, etc... The same principle applies to the piston rings, where 2ppm of Chromium is considered high wear for such a small part.

Where do the other elements come from, and do they indicate engine wear?

The only other element to look for in low numbers, in addition to the wear metals listed above, is silicon. High silicon could mean a bad air or oil filter is not trapping dirt. The other trace elements are usually part of an additive package that oils use, and are not from engine wear. Looking at the numbers of these other elements can be useful in determining if a manufacturer has changed their formula, or to see what type of additives they use. The most common other elements found in an oil sample and what they commonly indicate are:

Silicon: dirt ingestion, sometimes used as an anti-foamant

Molybdenum: anti-wear additive and friction reducer

Boron: anti-wear additive and friction reducer

Calcium: common additive with many functions, primarily a detergent

Magnesium: common additive with many functions

Phosphorous: anti-wear additive and friction reducer, shear stabilizer

Zinc: anti-wear additive and friction reducer, shear stabilizer

What do the viscosity numbers mean, and how do I read them?

The viscosity numbers are from a specific test to determine the viscosity of an oil at a given temperature, as measured in cSt (centistokes). A higher number means a thicker oil at operating temperature, and a lower number means a thinner oil at operating temperature. A higher or lower number is neither good or bad in and of itself, it is merely a measure of the oil’s viscosity. Some oils thinned out, or sheared, from use and became thinner than their original grade. For example, a used 30wt oil might have viscosity numbers which correlate with a 20wt oil, indicating it is prone to shearing in the VQ.

Are higher or lower TBN numbers better, and why don’t all the oil results have a TBN number?

All engine oils break down with use and time. The result is an accumulation of acids in the oil. These acids are what form sludge. The oil’s base stock and the additives in the oil work together to help prevent sludge from forming. The Total Base Number (TBN) is a measure of how well the formulation is working to fight sludge and acid build-up. A high TBN means there is more base than acid in the used oil. A lower TBN number means more acids formed over time than in an oil with a higher TBN. The TBN of a used oil is a good indication of how robust the oil is for extended oil change intervals, with higher TBN numbers indicating an oil is good for longer oil change intervals. It usually costs extra to get a TBN test done, so not all of the samples have a TBN value.

Won’t residual oil from a previous oil change affect the UOA results?

Won’t residual oil from a previous oil change affect the UOA results?

Not usually. The amount of oil remaining in the engine after draining the crankcase is less than half a quart on average. Several members have posted their UOA’s with a particular oil, and then switched to one of the better performing oils. Their next UOA result was always consistent with the collected UOA results of that same oil, and demonstrated the higher performing oil to reduce engine wear compared to the previous oil despite any residual from the previous oil. Old oil left in the crankcase might affect the life span of the new oil, however, should their be a large enough quantity of remnant oil to lower the TBN of the new oil.

Won’t oil filters affect the number of wear metals that show up in a UOA?

No. A Used Oil Analysis only measures particles 5 microns and smaller, which is smaller than what oil filters can filter. Oil filters are actually measured by their ability to filter out particles 10 microns and larger. It is possible, that a very poor oil filter might allow very large particles to circulate through the system, rather than filtering them, which could cause extra wear. Use a quality filter and there shouldn’t be a problem.

Which oil filter should I use?

There are several good filters out there, and this site:

http://motorcycleinfo.calsci.com/FilterStudy.html covers the same filter as used on the VQ35 with all the information you need to pick a good one. The only thing I will add is that for extended oil drains, a synthetic media filter has been shown to maintain filtering efficiency longer than other filters. So, if you plan on going longer than 7k miles on an oil change, I recommend a good synthetic filter like Mobil1, K&N, or Amsoil. For further explanation of filtering efficiency and beta ratios, here is an article by Jeremy Wright at Noria:

http://www.machinerylubrication.com/article_detail.asp?articleid=1289&relatedbookgroup=Lubrication

What does the oil weight actually mean?

An oil’s weight refers to it’s measured viscosity at a given temperature. The temperature of the oil is important when measuring it’s viscosity because an oil becomes thinner, or less viscous, when it is heated. Conversely, oil becomes thicker, or more viscous, when it is cooled. Because oil viscosity changes with temperature, an oil’s weight is determined by the measured viscosity at a specific temperature (100 deg C). The unit of measure is called a centistroke (cSt). The higher the measure of viscosity at 100 deg C in centistrokes (cSt), the higher the oil’s weight. The following chart shows the viscosity an oil must be at a given temperature for each oil weight.

So how does that translate into the weight I see printed on the bottle, like 10W-30?

So how does that translate into the weight I see printed on the bottle, like 10W-30?

Some oils are straight weight oils, like a straight 30 weight oil. This means the oil is always a 30 weight oil at any given temperature. The oil still thins out with heat, and thickens up as it cools, but at any given temperature it will measure within the specs for a 30 weight oil at that temperature. This is not good for your engine during cold starts or in cold weather, because a 30 weight oil is very thick when it is cold. Thick oils are harder to pump and therefore don’t flow through the engine and lubricate very quickly. The solution is a multi-grade oil. A multi-grade oil is still thicker when it is cold than when hot, but not as thick as a straight weight oil. In the case of a 10W-30, the “10” refers to the oil’s “Winter” weight (hence the “W”). A 10 weight oil is thinner than a 30 weight oil at cold temperatures, and thereby flows easier to properly lubricate the engine upon start-up. As the engine reaches operating temperature, the oil thins out- but does not stay a 10 weight oil. It becomes a heavier weight, and in this case, becomes only as thin as a 30 weight oil at operating temperature. Here is a simple chart, courtesy of Noria, that shows how a 10W-30 compares to straight 10 and 30 weight oils.

What winter weight should I use, a 5W, 10W.. etc?

What winter weight should I use, a 5W, 10W.. etc?

Since the majority of engine wear occurs during start-up, it is important to use oil that will flow well and lubricate the engine quickly during this time. Remembering that oil is thicker when cold, the proper winter weight is one which provides the maximum amount of flow for the given ambient temperatures when the engine is started. The colder the temperature of the oil, the harder it is to pump, so a thinner winter weight is beneficial during start-up. As ambient temperatures increase, the oil will thin out and start to get closer to its operating grade, and at some point, multi-grade oils like 5W-30 and 10W-30 will be close to the same viscosity for a given ambient temperature. This means that there is no harm in using 5W oil even in hot climates. As an example, the start-up viscosity of a 5W-40 and a 15W-40 may well be the same if the ambient temperature is hot enough. This also means that heavier winter weight oil (such as 15W-xx) may be used if the ambient temperatures are warm enough to ensure that it can be pumped quickly enough to properly lubricate the engine during start-up. The importance of selecting an oil with proper start-up viscosity is paramount, and is why auto manufacturers recommend winter weights based on the ambient temperatures with charts similar to this one:

Are 0W-xx oils too thin for my engine?

Are 0W-xx oils too thin for my engine?

As discussed previously, multi-grade oils are designed to behave like two different oil weights at two different temperatures. Since an oil is thicker with colder temperatures, a lower weight oil flows better, and better protects the engine during start-up since it is easier to pump to critical areas. So, a 0W-xx oil is a better oil for start-up, especially in cold temperatures. When the oil heats up and starts to thin out, it becomes a heavier weight oil just like a 5W-xx or 10W-xx oil would. So, a 0W-xx oil is only a “thinner” oil when it’s cold- where it is a benefit. At operating temperatures, a 0W-30 is the same weight as a 5W or 10W-30, just as a 0W-40 is the same weight as a 15W-40, etc... Therefore, 0W-xx oils tend to be better suited for year-round use in any climate, since they flow better in cold temps but become as thick as any other similar grade oil when hot.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top