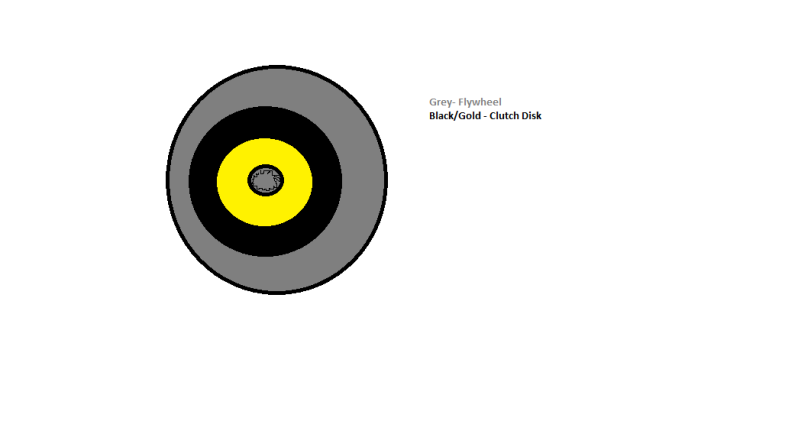

If you havent noticed, the holes in the trans are larger than the bolt, the trans has probably a good 2-3mm movement in each direction without the dowel pins that you could still get all the trans bolts in and it would look like its on just fine but probably sagging a little or a little twisted clockwise or counterclockwise. In other words, the input shaft wont be centered on the clutch and this will put tremendous pressure on the disk itself. Once engaged, if the clutch isnt sitting perfectly center on the flywheel and pressure plate you will have a very very heavy vibration on the clutch disk and input shaft due to spinning in a not so perfect circle. Basicly while at one part it sits nice and even with the input shaft while at the opposite end it pushes outward or pulls inward on the shaft and the disk gives before the input shaft. Plain and simple. If you still dont understand it, I will draw you a picture.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top