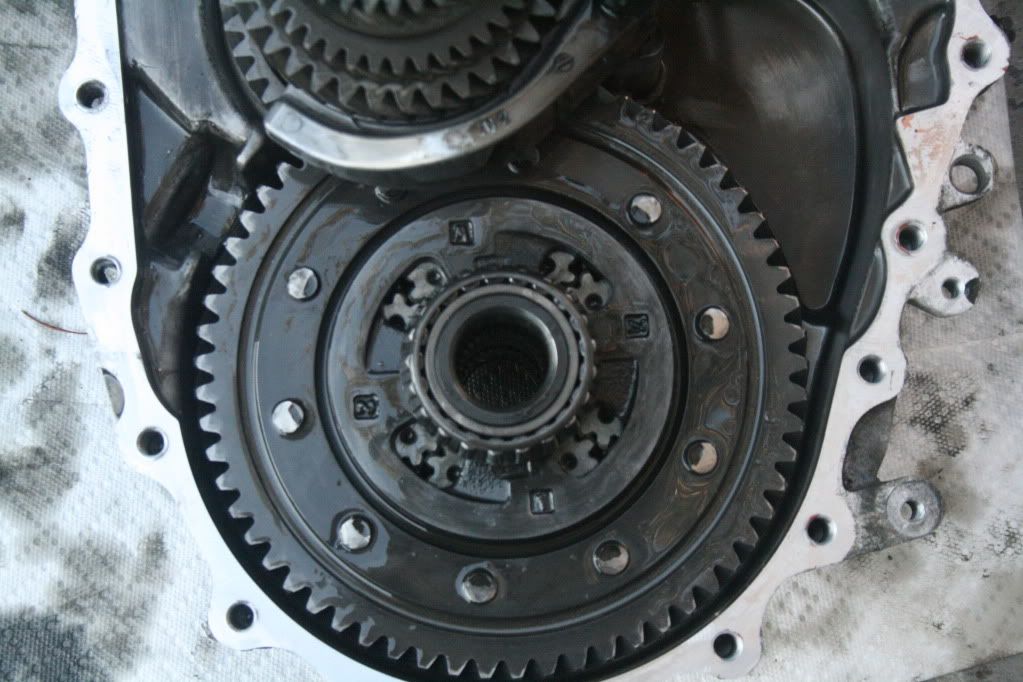

As an Engineer, I'm amazed so much stress would end up on that particular part of the case, I'm guessing the Differential is pushing outward on that one spot.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.