I'm replacing the lower ball joint on my G20, which is a pain in itself because it's essentially a double wishbone front.

I've loosened the crown nut as much as possible to get the spindle off of the lower control arm. It will not budge!! The spindle is very much stuck onto that bolt. Now, in every setup I've replaced the lower ball joint. You just take that nut off, the spindle lifts off the ball joint, then you can proceed to remove the ball joint.

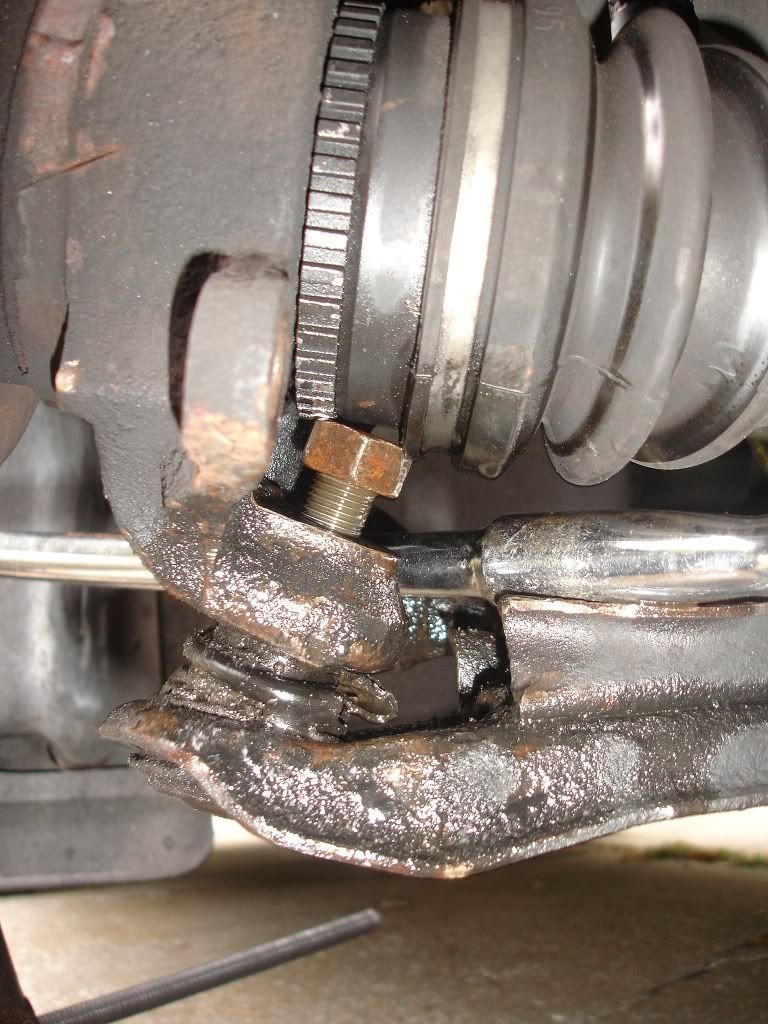

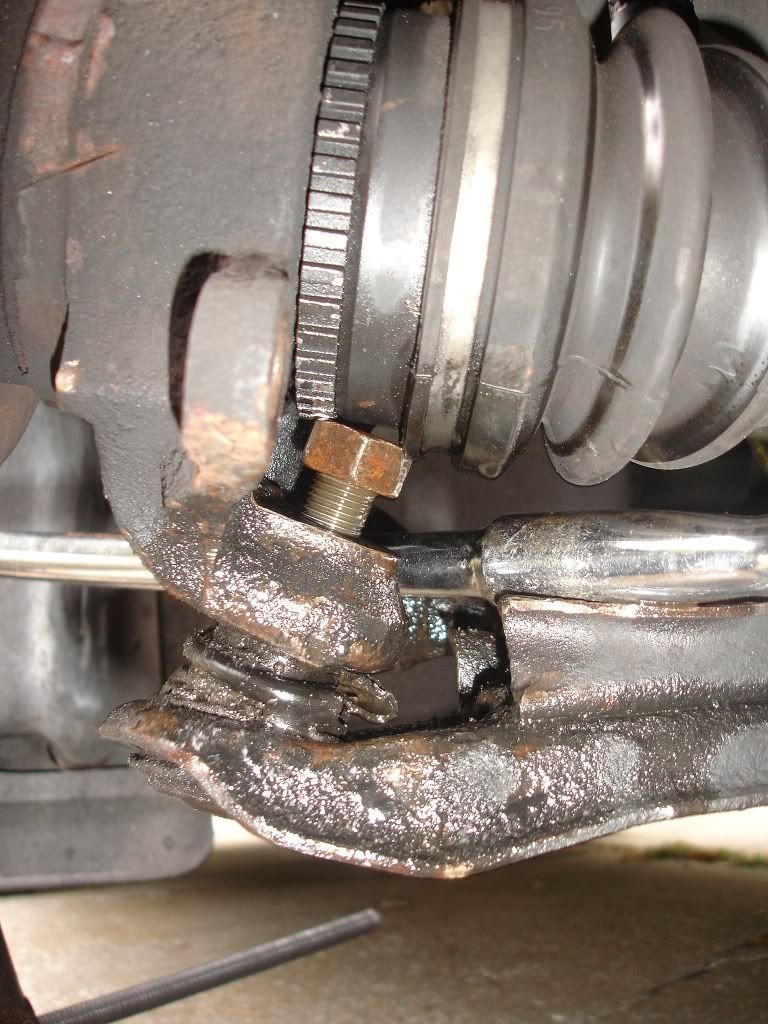

In the picture, you can see the breaker bar in the middle. I'm basically using the weight of the car to separate the 2, but they are not coming apart. I've sprayed liquid wrenck all over the area, even let it sit over night.

I've loosened the crown nut as much as possible to get the spindle off of the lower control arm. It will not budge!! The spindle is very much stuck onto that bolt. Now, in every setup I've replaced the lower ball joint. You just take that nut off, the spindle lifts off the ball joint, then you can proceed to remove the ball joint.

In the picture, you can see the breaker bar in the middle. I'm basically using the weight of the car to separate the 2, but they are not coming apart. I've sprayed liquid wrenck all over the area, even let it sit over night.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top