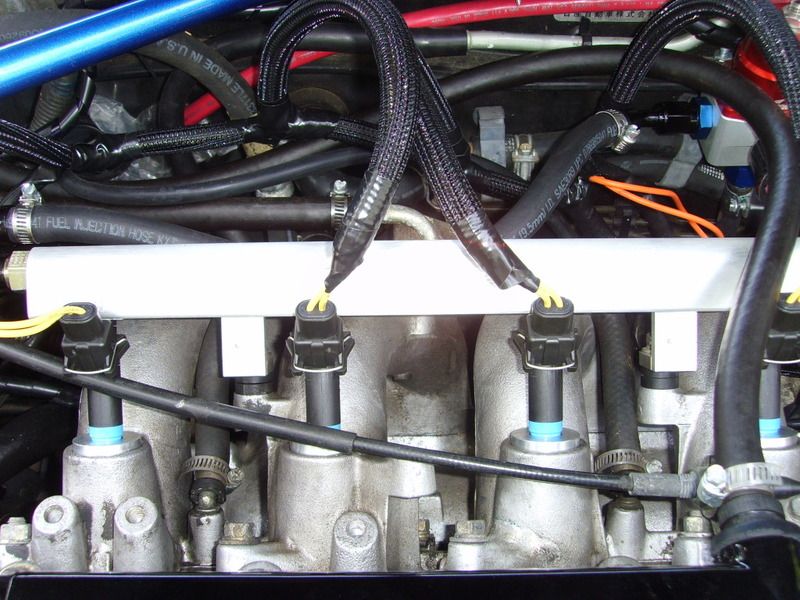

I had a shop make an aluminum slug to fit where the stock rubber was

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. lynchfourtwenty likes this post.

lynchfourtwenty likes this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. unijabnx2000 likes this post.

unijabnx2000 likes this post.