Being an EMS user, although I don't run a turbo, I'll see if I can take a stab at it.

If you were N/A I'd lean towards a gasket leak, however, to suck in enough air to get to 5,000RPM, the air has to be metered, once again, you're running a MAP, so it adds to the unknowns.

If you had an actual leak in the piping, e.g a gasket leak, I'd imagine, you'd know already because you're boosting. Of course, you should be at a vacuum inside the I.M. since the throttle body is shut.

Anyway, the most likely scenario is too much air is getting past your throttle body or your IACV or your AAC. The AAC valve and IACV are 2 separate units, the AAC is under the I.M, the IACV is usually on the far end of the I.M opposite the throttle body.

Here's what I suggest you do.

First off, take off your throttle body. Clean it, inspect it, make sure it shuts completely, check for cracks or missing screws. Second, remove the IACV and AAC units completely, seal the hole with a gasket and plate.

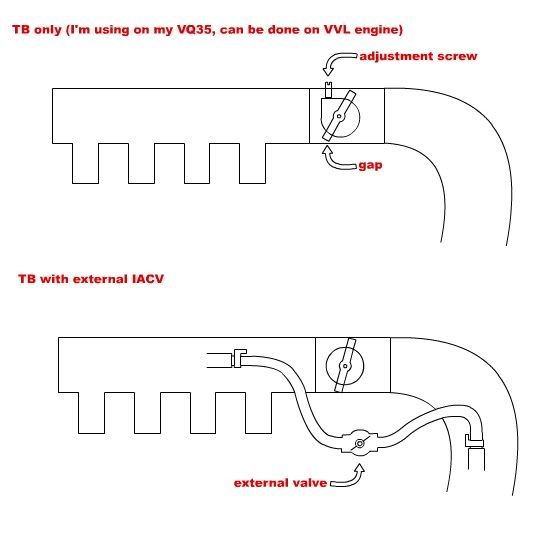

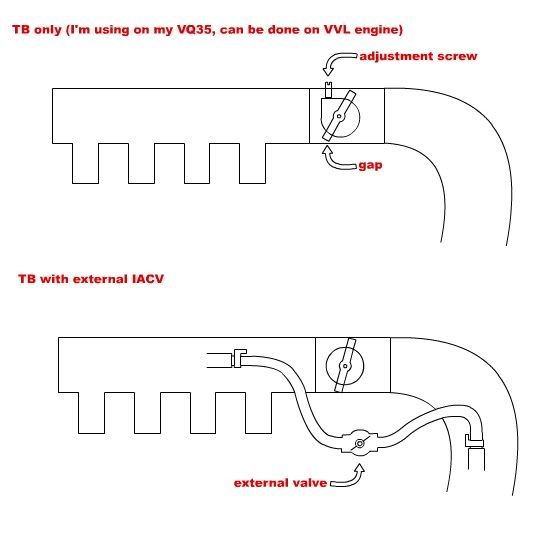

Make your own IACV. Utilize one of the nipples on the I.M, such as the PCV or Brake Booster port. Run a line straight from the boosted side of the throttle body to the vacuum side of the throttle body and literally, put a valve on that line that you can adjust by hand.

My AEM has a very steady idle with no IACV, I just adjust the incoming air and I'm done.

Here's a drawing of my suggestion:

If you were N/A I'd lean towards a gasket leak, however, to suck in enough air to get to 5,000RPM, the air has to be metered, once again, you're running a MAP, so it adds to the unknowns.

If you had an actual leak in the piping, e.g a gasket leak, I'd imagine, you'd know already because you're boosting. Of course, you should be at a vacuum inside the I.M. since the throttle body is shut.

Anyway, the most likely scenario is too much air is getting past your throttle body or your IACV or your AAC. The AAC valve and IACV are 2 separate units, the AAC is under the I.M, the IACV is usually on the far end of the I.M opposite the throttle body.

Here's what I suggest you do.

First off, take off your throttle body. Clean it, inspect it, make sure it shuts completely, check for cracks or missing screws. Second, remove the IACV and AAC units completely, seal the hole with a gasket and plate.

Make your own IACV. Utilize one of the nipples on the I.M, such as the PCV or Brake Booster port. Run a line straight from the boosted side of the throttle body to the vacuum side of the throttle body and literally, put a valve on that line that you can adjust by hand.

My AEM has a very steady idle with no IACV, I just adjust the incoming air and I'm done.

Here's a drawing of my suggestion:

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top