ashtonsser

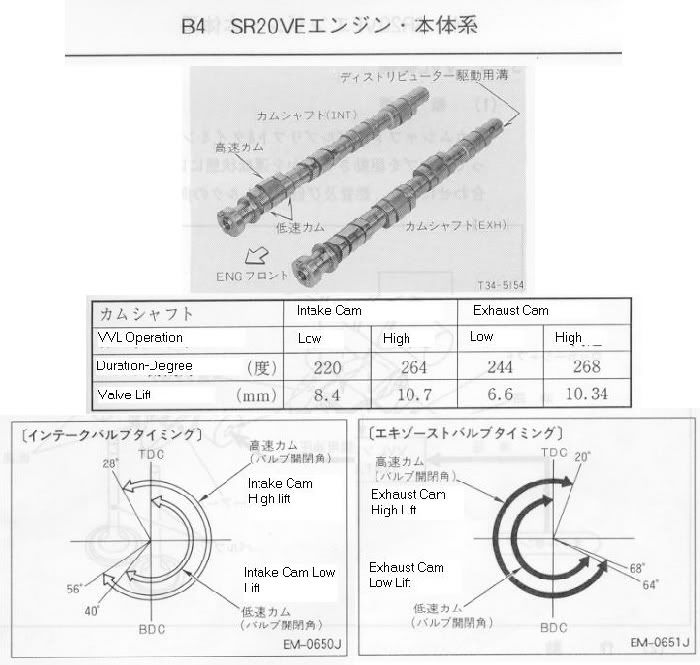

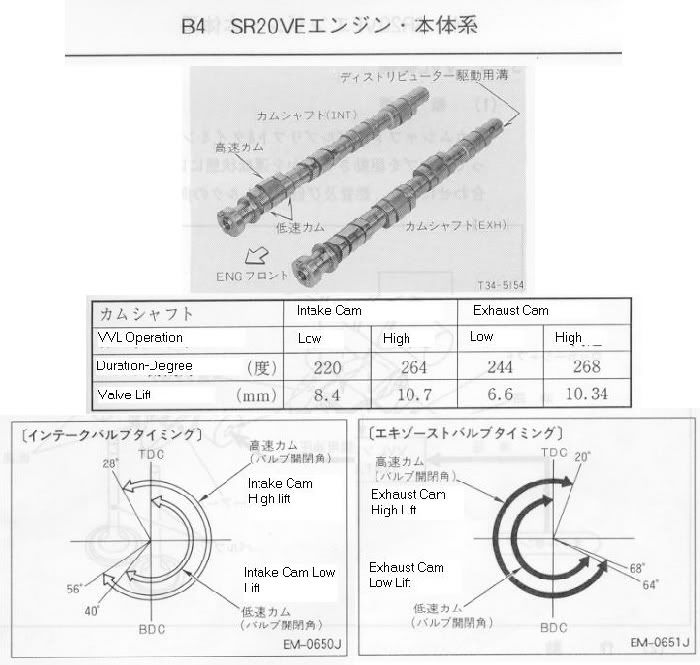

here is the degree card for the standard cams

now if you feel safe running on high ex cam at idle you can basically have the high ex on all the time and take out 20 deg of overlap, leaving you with 28 deg which is a nice amount of overlap on a turbo set up. It also means the log will be more efficient and since your goals are quite low, the response of the log manifold could be beneficial to you. There is also the cost benefit since you already have the log

i have not tried this, so i am not talking form first hand experience, but i dont think you would run into oil pressure problems down low with the high ex cam engaged all the time, but if you are worried maybe a gtir oil pump could be used

p11 - 77mm diameter / 11.9mm thick

gtir - 80mm diameter / 14.3mm thick

however maybe mrslappy could shed light here to whether you will run into problems?

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top