THE ULTIMATE 6 SPEED SWAP THREAD/HOW TO

OVERVIEW

We all know the weakness of the b13/b14/b15/p10/p11 transmissions. While the b13/b14 transmission is known for its smooth feel and shifting it is plagued with brittle weak gears and a brittle weak case that tends to crack under even slight wheel hop or hard launches. 3rd and 4th gear like to break with anything more than about 350whp or so and hard use. While you can do things to prolong the life of the transmission like cryro treating the gears and case and using a heavy weight gear oil as I like to do, such as 85w140 Valvoline Conventional and Durablend, which I've had great results with extending the life of the gearbox 4-5X than without at roughly 460-550whp ranges.

The p11 and B15 transmissions while they have a stronger case and slightly stronger gears due to added size and tooth profiles and benefit from changes such as having bearings on both the input and mainshaft at the back half of the case to help keep the gears from spreading causing sheering of the teeth are still known to still break in the 400+whp range with hard use. They are also not as smooth as the earlier transmissions due to the changes in how the shift rod, actuating, and forks are mounted and controlled. They tend to want to lock you out under quick shifts and especially no lift shifts usually into 2nd and 3rd gear.

The Ultimate solution to all of our transmission problems is the use of the P12/02-06 Spec V/ 02-06 Maxima transmissions/gearsets. These transmissions are known for their much larger diameter and thicker gears along with a much deeper tooth profile. I have yet to see one of these break in fwd application. The gearset is the same gearset used in the Evo 8/9 MR 6 speed and the Evo guys are known to break 4th gear at 500+awhp and hard use. You also have to take into account the street tires, awd, and 3000+ lb weight of the Evo. The fwd application will put much less stress on the gears. Coheed ran his at 450+whp daily and over 500+ on occasions with zero issues. So far mine has held up between 600-716whp both on the street and multiple drag passes with no issues. You benefit also from the added 6th gear which in the 03+spec V transmissions will result in roughly 950-1000 rpm less at highway cruising speeds vs a b13 transmission which should greatly help pick up some MPG's.

This thread will go over all the parts you can use to complete the swap, price ranges both new and used for the parts, details on installation, and results for different setups.

PARTS REQUIRED FOR THE SWAP ALSO FOR DIFFERENT POWER RANGES AND APPLICATIONS

TRANSMISSION CHOICES

First thing in the swap is choosing which transmission/gearset is right for your application. If you need help finding what year the transmission is, well its a good thing all these transmissions come with a VIN plate attached on the gearbox. 10th character of the vin will give you the year. Or just plug it into something like carfax or autocheck and it will give you the year and model it came from. You can even pull a history report and see what mileage was on it and what happened if you so desired. I did it with mine as I had an extra carfax report I wasn't going to use. Turns out mine was very low mileage and car was in a rear end collision. Good stuff.

The p12 gearbox while would be the easiest and cheapest route with a price range used from $800-$1200 depending on mileage and it already has the correct bellhousing on it. No need to tear it apart to swap internals into the p12 housing. Downfall of it is that the P12 gearbox does not have HLSD that the Spec V and Maxima gearboxes come with. The HLSD is a huge benefit over the old VLSD of the older boxes. This box has short gearing that is great for N/A applications

Second option is the 02-06 Nissan Sentra SE-R Spec V 6 speed gearbox. All of these boxes have the HLSD Differential. The 02 box has slightly shorter gearing than the 03-06 boxes do. The FD was changed from a 4.4 to 4.1 in 03. (See information below) The 03 is close to the same gearing as the 04+ box with a slightly shorter 6th gear. Also there was some revisions to syncro issues in 03+ boxes that the 02 boxes had. Your best bet is to get the 04+ box which is what I currently use. The 04+ boxes have longer 6th gear which will be good for turbo applications and get the best mileage.. This requires you to swap the internals over to a P12 bellhousing to mate to the SR20 Block. These transmissions can be purchased used from a price range of $300-$500 on average depending on mileage and are very readily available.

02 Spec V gear ratios

3.417

1.944

1.258

.947

.773

.630

R-3.252

Final Drive : 4.429

Gear Ratios 2003 6 Spd Spec V

1st 3.153

2nd 1.944

3rd 1.392

4th 1.055

5th 0.809

6th 0.673

Reverse 3.002

FD: 4.133

04 B15 RS6F51H

1: 3.153

2: 1.944

3: 1.392

4: 1.055

5: 0.809

6: 0.630

R: 3.002

Final: 4.133

Third option is the 02-06 Maxima 6 speed gearbox. All of these boxes have HLSD Differential. It uses the same gears but the 02-03 6 speed benefits from the longest final drive which is a 3.81 vs the normal 4.133 seen in the 03.5+ maxima boxes and the 04+ Spec V boxes.. Estimating about a 1200 rpm drop vs what you would see in 5th gear on a b13 transmission. Again this requires you to to swap internals over to a P12 bellhousing. See below for the actual guide on the parts. There is a split in the years of what transmissions came with what parts. Early 03 came with the 3.8 FD, 03.5 so to say came with a 4.1 FD. All the gears are the same ratios just changes to the final drive.

06/01-12/02 PN 32010-5Y774

Use's Gears

1st 3.153

2nd 1.944

3rd 1.392

4th 1.055

5th .809

6th .630

Rev. 3.002

F/D: 3.81

01/03-08/05

PN's 32010-7Y076 01/03-02/20/04 and 32010-7Y476 02/21/04-08/05

All use the same gears

1: 3.153

2: 1.944

3: 1.392

4: 1.055

5: 0.809

6: 0.630

R: 3.002

Final: 4.133

So as you can see, if you wanted to give yourself the absolute longest gears, use the 02-03 Maxima gearstacks and FD into the P12 bellhousing as well as use the HLSD This would give you a nice long cruising gear.

DISCLAIMER: Mazworx offers engine to transmission adapter plates to bolt the Spec V gearbox onto the SR20 engine but requires you to have the bell housing machined down the width of the adapter plate to fit properly. I dont know anyone who has gone this route yet as its easier to just get the P12 bellhousing which can be purchased from either Mazworx or from Greg at Gspec Performance. Both are vendors on this forum and can be contacted on here or through their sites. Links below:

OEM P12 Transmission Bellhousing - Drivetrain - Mazworx

G Spec Performance

Cost of the bare bellhousing is between $300-$350 brand new.

CLUTCH/FLYWHEEL SETUPS FOR DIFFERENT APPLICATIONS AND POWER GOALS

This section will go over the different clutch/flywheel setups starting from cheapest to most expensive.

1. Cheapest route would be to find a P12 OEM dual mass flywheel and clutch assembly used. While rare you can pick a setup up for $200-$300 or so used. The setup would be fine for those wanting a basic setup for N/A application. However, the dual mass flywheel is for one heavy and two is plagued with noise issues when they are older and worn due to its design. This is a bolt on application and requires no grinding or any modification to fit. You must use the p12 flywheel bolts as they are significantly longer. So make sure to get all the parts necessary. I would guestimate power wise this setup would be good to about 200whp or more. Vadim is currently in the process of taking measurements to make sure the p12 and DOHC 240sx/Altima 225mm clutch is the same and can be used as a replacement clutch for this setup. Stay tuned for updates with measurements and pictures.

2. Gspec Performance 6 speed swap flywheel: Aluminum Flywheel 2.0, Sentra B13,B14,B15 2.0 6 speed swap vvl

Straight from the site, at a cost of $550, this flywheel weighs only 11.9 lbs and uses a 225mm 240sx KA24DE clutch kit which you can get clutches to support pretty much any power range up to about 600-650whp or so using clutches like ACT or Clutch Master units. I believe all clearance issues have been taken care of with the most current line of flywheels. I know Coheed got one of the originals and it required some machining to clear the bellhousing. This is a bolt on application.

3. JWT 6 speed swap flywheel. This flywheel is currently under revision due to clearance issues with the originals that required extensive grinding to clear the bellhousing. The flywheel can use a 240mm and 250mm clutch from a 350z or S15 The clutch clearance also required some grinding as well. Priced at $425 new this also gives you an option for some serious holding capability on the clutches with a very streetable feel due to the large surface area. Clutches that size can hold upwards of 700+whp with a strong enough setup. Contact JWT for more information on the setup.

Jim Wolf Technology website

4. The s15 flywheel/clutch setup is another option. As test fitted by tswii, the measurements come out to the same as the p12 flywheels setup. The clutch to use is either a rwd sr20det clutch which can be found online most places and through pretty much every aftermarket clutch company. The clutch is a 240mm clutch setup. The issue with this setup is that the pressure plate and outer edge of the mating surface hits the starter area on the bellhousing. You would need to grind away approximately 4-5mm or have the pp and flywheel machined down. With this setup you can also use the 89-94 Nissan Maxima Clutch setup which turns out to be the same, only issue with this clutch is that the pressure plate sticks out off the edge of the flywheel requiring more area to be ground down from the bellhousing or to be machined down. Whichever way you choose. Details of the setup can be seen here with the Maxima clutch setup.

http://www.sr20-forum.com/866832-post49.html

I believe if you get a RWD DET clutch setup the pressure plate wont protrude out past the edge of the flywheel so it might be the way to go.

5. The last option is one that I worked directly with Dan at Competition Clutch to design and make a Twin Disk Clutch setup for the swap. Thanks to Andreas Miko for providing the p12 flywheel for measurements. This twin disk flywheel/clutch setup uses a two piece design on the flywheel that extends the mating surface of the clutch out approximately .500" to bring the clutch out where needed. The disks are your normal 240sx twin disk 24 spline 1" input. The setup bolted on with zero issues and a new TOB is provided with the kit. Price is $1250 for the entire setup brand new from Competition Clutch. Link Below: This setup will handle pretty much anything power wise you can throw at it and is meant for drag applications but is also pretty streetable once you get used to it. It is what Im currently running on my car and its proved itself over and over. Very very nice clutch setup. It is a fully balanced setup and ive personally taken the setup to 10K+ RPM revs with no issues. If your looking for the ultimate holding solution and overall one of the cheaper solutions, look no further than this setup.

Products

Pics of the setup below:

For your normal single plate clutch setups your looking at anywhere from $300-$500 new depending on what brand and Stage you go with. Pick your clutch dependant on your power goals.

For the Throwout bearing you would use the p12 or Spec V bearing. I wanna say the 240sx one is similar if not the same as the Spec V. Don't quote me. Others can chime in on which ones they used. For my twin disk setup it came with a new bearing that gets pressed into the Spec V bearing housing. You knock out the old one and press in the new one. It can be done without an actual press. It comes out and goes in pretty easy.

MOTOR MOUNT KITS

The only mount kits I know readily available are the Mazworx mount kits. This is a bolt on application for the b13/b14/p10/b15. The p11 requires modification on the transmission mount in order to do the swap. The kit includes the transmission side mount that bolts to the frame in replacement of the original mount brackets for the 5 speed, the new rear mount bracket, an axle carrier bracket (you must specify DE/VE or DET as they are different) and all the new hardware to mate the p12 transmission to the SR20 as the bolt lengths are different. Link below: Kit is priced at $399

Mazworx QR 6 speed conversion mount kit - Drivetrain - Mazworx

A second option if your lucky enough is to find the p12 transmission mount and it has proved to be a bolt on application as well. You could use either the Mazworx rear mount or make your own and use the Mazworx carrier or if you have a DE/VE use the p12 axle carrier if your lucky enough to find one.

Pic below of the p12 transmission mount bolted in place on a b13

[/QUOTE]

[/QUOTE]

HYDRAULIC CLUTCH CONVERSION FOR B13/B14/P10

For those of us without a P11 or B15 we are required to convert the clutch to hydraulic as the p12/SpecV transmissions use hydraulically actuated clutch forks.

There are a couple ways to go about this procedure. There is the use of the b15 clutch and pedal setup. This requires modification to the pedal and firewall to get the pedal to sit properly. All the install of the b15 pedal and clutch master cylinder can be seen here:

http://www.sr20-forum.com/turbo/23692-converted-clutch-b15-hydro-setup.html

I have done 3 conversions this way using the b15 pedal assembly and all are working perfectly. Its difficult to get the pedal to line up in the old clutch pedal position but if you take your time it can be close enough that you won't be able to tell.

The next way and so far the easiest and simplest way is using a 4th gen (94-99) Maxima clutch pedal and master cylinder assembly. On a b13 its a bolt in affair, no cutting, no redrilling, and no modifying for the upper securing bolt. On a b14 it requires modification to weld a new tab for the upper mounting bolt. Pretty simple. It bolts in and aligns the pedal perfectly to the old position. Just mark where the new tab needs to go and then weld one on and done. You have to notch the ridge on the firewall where the master cylinder reservoir will hit to allow clearance. Here is Manny's install of his Maxima pedal. Thanks again for the information.

http://www.sr20-forum.com/862864-post253.html

For the p10 guys I believe it applies the same as the b14 guys. Ive also heard through the grape vine that a p11 clutch pedal assembly might work just as well. Again haven't had anyone confirm and I will update as more information comes in.

Price wise, you should be able to pick up the pedal, clutch master cylinder, and line to the slave cylinder for under $200. You can use any year b15 pedal assembly, doesnt matter if its the Spec V or the 1.8L. Its all the same. Same with the 4th gen maxima setup. If you look around you can find deals on these parts. I usually get mine between $75-$100 for the whole setup.

As for the second half of the conversion, the slave cylinder. So far only two slave cylinders are known to work. The p12 and GTIR. Both are at times hard to find but Greg V and Mazworx are the known suppliers for them.

OEM P12 Slave Cylinder - Drivetrain - Mazworx

Slave cylinder is priced at $40

SHIFTER AND CABLE ASSEMBLY

Part of the conversion requires ditching the old school shifter assembly that uses a arm and stabalizer that attaches to the shift rod on the transmission. The 6 speed uses a cable actuated shift mechanism. The shifter is a solid box mounted inside of the vehicle (preferably) and cables that go to the transmission and secure to the shift actuator assembly on top of the trans. The cables are held onto the trans via a bracket with U-Clips. Make sure to get the transmission side bracket with the transmission along with the clips. You can use the p12/Spec V/5 speed manual QR25 Altima/6 speed Maxima bracket. It all mounts the same.

Couple different shifter/cable assemblies you can use.

First one is the Spec V shifter assembly which Manny is currently using. It is a bit more low profile of the other choices and works well. Here is Mannys install of it.

http://www.sr20-forum.com/members-rides/53664-manny-s-b14-same-book-different-chapter-update-4-14-2013-a-6.html#post862422

The second option is using a 5 speed QR25 Altima shifter assembly and cables. The difference is its not quite as low profile as the spec v but you can cut the excess off (mounting points for the Altima console) and make it pretty low profile. Good thing about this assembly is that the rear bolts line up perfectly where the shifter bushing bolted to by removing the stud plates. Then redrill front holes and done. It fits cleanly and perfectly. Another difference is the rubber plate on the Altima mounts on the inside of the vehicle. Pics of the Altima shifter assembly mounted below:

Last option is to use the Maxima shifter assembly. It might require more trimming but should fit the same but it is slightly more bulky. Your best bet is to use the Spec V or Altima setup.

Price for shifter assembly with cables used should be $50-$150 I would say depending on the yard. I got my Altima setup for $40 but again I give the yard a lot of business and he knows me so he hooks me up.

AXLES/HUBS/BRAKES

Moving onto the axles, hub, and brake options with this swap. Another added benefit from this swap is the much larger axles including the larger hubs and outer cv joints. These axles are beefy compared to the older axles and should withstand a ton of power and abuse. The axles use a 36mm nut vs the 32mm on the b13/b14. The p10/p11/already have the larger splined hubs and axles so there is no need to swap anything. This is strictly for the b13/b14/b15 guys.

You have a couple options here starting with the cheapest first and something that I worked directly with DriveShaftShop (DSS) to develop and produce with the help of Josh @unijabnx2000 for taking in his hubs and axles.

1. The first option which is by far the cheapest and easiest is to send a set (preferably new) b13/b14 hubs to DSS where they will drill and respline them to the larger spine of the Spec V axles. The cost on this is $100 if you send in BNIB hubs and $150 for used hubs because they require cleaning before machining can be done. This allows you to keep all your current brake and knuckle assembly and is a done deal. You can get a hold of Tad or Frank at DSS at the following link. Just tell them you want the procedure done for the hub to be resplined to the Spec V axles. Simple as that, its a couple day turnaround as well. For you drag guys this allows you to keep your B13 SE-R or NX brakes so you can also run a 13" drag wheel with no issues. A 13" drag wheel will in no way shape or form clear the stock B15 brakes. So this is by far the simplest and easiest option. There should be no reliability issues with this setup and the size of the new splines is comparable to DSS's 5.9 Series Honda axles with the exception of not having Chromoly outer joints. Either way it should handle whatever you can throw at it.

The Driveshaft Shop | Home page

DISCLAIMER: There is one member on here who did the swap and had issues with the driver side axle being too long causing binding of the CV joints which under high hp (above 600whp) they would snap at the midshaft. Happened twice. Although his car is very low as well taking up any compression the axle might have due to it being low. So far neither I nor Coheed have had this issue but our cars are only slightly lowered. A fix for this is to swap the b13 midshaft onto the Spec V inner and outer joint. They use the same spline size. Just swap the 3 roller joint for the inner and then install into the outer joint and done. This will shorten the axle and give that extra compression and should solve any issue.

The next option is to just swap to B15 Spec V (YOU CAN'T USE THE 1.8L or 2.0 B15 HUBS AS THEY ARE DIFFERENT SIZE SPLINES) B15 hub, knuckle, and brake assembly setup. Keep in mind the hubs are 4X114.3 vs the 4X100 so you can either redrill the hubs to 4X100 or get new wheels if you dont have dual bolt pattern wheels. The knuckles are direct bolt in to our cars but you may consider getting an alignment done after completed as Coheed found out the steering alignment will change with the new knuckles. Coheed used the opportunity to swap out his entire setup for a Brembo Spec V setup front and Rear. The b14's can benefit from the B15's superior beam and rear setup vs the B14's as well as so he could use the 4X114.3 bolt pattern all around. The entire procedure can be found here:

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

This is the more expensive and costly way to go. Your probably looking at about $150-$300 for just the regular Spec V B15 brake setup, knuckles, and hubs. If you go with the brembo ones your probably looking at $600-$1000 depending. For the rear beam and brake setup from a B15 your probably looking at $200-$400 depending.

If you decide to go with just the front setup and convert the hubs to 4X100 your probably looking at $50-$75 for a machine shop to redrill the hubs and then the cost of new studs at about $30 for oem or $80 for ARP extended.

As for axles you can use p12 or 02-06 Spec V axles. These are the only ones that will work. You can pick them up used for about $125-$175 for both as well as aftermarket new for a bit more. I found mine low mileage OEM red axles used for $130 shipped for both on Ebay. As most of you know I was successful in doing a hybrid swap with my axles but Im putting this out there now, don't try to follow what I did. I got lucky with the right year and model axle that allowed me to use the B13 outer joint on the passenger axle. Coheed and several others were not soo lucky and wasted a lot of time trying. Thats why I had DSS do this conversion so its straight forward and simple for those not wanting to deal with B15 hub/knuckle swaps.

DETAILED INSTALLATIONS

TRANSMISSION INSTALL/GEARSTACK SWAP

First up is the swapping of the gearstacks to the new/used p12 bellhousing. Its a pretty detailed and lengthy procedure. Coheed has the most intricate write up of anyone so we will be using his. Make sure that when you get your trans to get the new connectors for the reverse and neutral safety switch as they are different. Your reverse switch is the one located on the top of the transmission (blue sensor) the other is the neutral (black sensor)

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

On the transmission installation, if you are making your own custom motor mounts and not using the Mazworx kit, you will need pretty much all new bolts. The starter bolts need to be significantly shorter and the trans to engine bolts need to be significantly longer. The ones provided in the mazworx kit use a 19mm head for the trans to engine bolts and 17mm for the smaller M10 bolts. Thanks to Tswii for doing some measurements. Here is a layout of the bolts needed.

Chrome Bolts, Stainless Steel Bolts, Metric Bolts, Socket Head Cap Screws, Grade 8 Bolts, F911 Bolts for about $15.00 shipped, and they are all grade 12.9 cap head bolts.

[/QUOTE]

[/QUOTE]

On my car I didnt swap the subframes so the b13/b14 subframe required notching to clear the much larger differential housing of the transmission. You will see where you need to notch. All you need to cut is the lip portion of the K-member/subframe. You dont need to cut all the way into it like I ended up doing. Cut just enough needed that way you wont have to weld up a filler piece like I had to. The clutch install goes without saying as its pretty straight forward just like any other. Make sure the clutch fork is properly secured to the pivot and TOB before installing the trans. Once up, check to make sure you have proper play in the TOB and that its not tight up against the Pressure Plate. There are two different size pivots, the p12 one and the Spec V one. Dependent on which clutch and clutch fork setup you go with will decide what one you use. I used the longer one with my twin disk setup.

Again here is Coheeds install:

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

And you can follow manny's install as well:

http://www.sr20-forum.com/members-rides/53664-mannys-b14-same-book-different-chapter-update-12-1-2012-a-15.html

And here is mine, starting with this page and goes for about 2 more pages until its in the car.

http://www.sr20-forum.com/members-rides/29127-9-second-b13-sentra-se-r-build-update-2-26-11-highway-pulls-slicks-26.html

Also with your transmission make sure to use the p12 or Spec V transmission mount bracket that bolts to the transmission. I tried to use the 5 speed Altima one and its a different height. Even though it bolts on, the mount bolt location is higher up which causes the trans to sit significantly lower which wont allow you to bolt up the crossmember. MAKE SURE TO USE THE SPEC V/P12 BRACKET

For you B14 and OBDII P10 guys, the p12 bellhousing has the provision for the crank sensor. It does require you to drill out the provision and tap a hole for the securing bolt. Take your time and everything should work properly with no CEL. The flywheels out I believe all have the 108 tooth profile so again to not trigger a CEL.

[/QUOTE]

[/QUOTE]

SHIFTER ASSEMBLY/CENTER CONSOLE

The shifter install is fairly straight forward. Whether your using the Altima shifter or Spec V shifter the install is fairly the same. The shifter assembly fits directly in place of the opening of the old shifter. You can mount it inside the cabin as designed and is the preferred way or you can mount it like I did the first time around and make custom brackets to mount it in the tunnel.

The difference between the two is if you mount it inside you dont have many options out for the console other than custom. You can fit the main part of the center console but the bottom tray and shifter surround will not fit. If you mount it in the tunnel as I did your whole center console will fit with no issues at all. However the shifter will sit very low. I could have mounted mine approximately 1"-2" higher with some trimming to the shifter opening in the tunnel to allow clearance of the shift cable levers. With a custom heat shield you could still run an exhaust in the tunnel as well with no issues if you get it up as high as you can. I had no issues with mine set up like that and it made the interior look stock. The p10/p11/b15 guys dont have this issue as there is plenty of clearance on the console side of things when you mount it inside.

If you go the mounting inside and want to keep it clean, make sure to get the rubber boot that seals the bottom of the shifter assembly and make sure to use the cable passthrough seal and bracket that bolts to the underside or top side if you use the Altima cables of the tunnel to make it nice and clean and sealed. On our cars you will see exactly where the cables need to pass through as there is a plate on the tunnel that you can cut out that would normally be for automatic vehicles where the cable passes through to the outside of the vehicle. You can see several installs here.

My in the tunnel install (B13:

http://www.sr20-forum.com/512687-post475.html

Manny's inside (B14):

http://www.sr20-forum.com/862422-post223.html

http://www.sr20-forum.com/862558-post225.html

My install inside the cabin (B13):

As you can see the rear bolts of the Altima shifter assembly lined up perfectly with the old holes for the mounting studs for the old shifter bushing. Drilled new front holes and installed new bolts.

You want to route the cables up between the subframe/k-member and the firewall directly in the center or if you still have the weight blocks on the b13 to the passenger side of the weight block.

Mount the cables on the trans bracket and secure with the U-Clips as seen here.

Coheed's Shifter install (B14):

http://www.sr20-forum.com/597287-post8.html

You can see the b14 has alot of extra room for the console. Looks like you could easily do a custom boot that would fill in all the gap and look clean.

MOUNT KIT INSTALLATION

The mount kit is pretty straight forward using the Mazworx kit. The new transmission mount bolts directly to the b13/b14/P10 frame using the supplied hardware. For the B15/P11 guys you need to modify it a bit and drill new holes or make a custom tranmission side mount that has the rubber mount on the trans side of things on the frame rail that way you can use the stock mount bracket on the frame. Pics of it mounted onto my B13 below:

The new rear mount bolts to the trans with two 17mm bolts vs 14mm bolts plus using one of the 17mm bolts through the block into the trans. I haven't experienced any issues with mine so far.

Rear mount pictures:

The mazworx axle carrier bracket is a very nice piece although its a two piece design. Coheed had an issue with the bolts that hold the two pieces together coming loose after extended mileage causing major vibration and noise from the axle. Be sure to either remove and loctite the bolts or have the two piece brackets welded together which is what I highly recommend to do. Should look like this when done:

For the trans mount be sure to use the aluminum spacers that come with the kit, one on each side of the mount. You might have to spread the bracket open a bit to get them in but make sure to use them or you might have issues with the mount trying to be pushed through by the bracket. I haven't had any issues with mine but Coheed's car did because none of the spacers were being used.

SPEEDOMETER

For you 93+ guys you can use the electric speedo that comes with the spec V or p12 trans with no issues. For us 92 and below models that use cable speedometers you can swap the speedometer cable drive/speed sensor over to the 6 speed. You need to cut off the tab for the securing bolt as the sensor needs to be rotated clockwise more from its normal location to seat right in the trans. Be careful when installing, one all the way down rotate it until you feel it hit up against something and that should be good. I used the normal bolt with a wide washer to secure mine and had no issues and the speedometer worked like a charm.

GEAR OIL RECOMMENDATION

Just like the B13/B14/B15/P10/P11 transmissions, the manufacturer calls for a 75w90 gear oil. I believe they call for GL-4 oil as well. For those putting heavy use or above 500whp on their cars I highly recommend using Valvoline 85w140 Conventional or Durablend in the trans except for winters in cold areas. Stick to a 75w90 Synthetic. The thicker gear oil is great in this trans. When warmed up it shifts buttery smooth and it will help prolong the life of the gears and bearings and allow it to take more abuse just like it worked in the B13 trans I ran before. I will leave your choice of oil up to you. That is just my recommendation. Coheed first used it as well and liked it but when it started to cool down some it made startups and the first few blocks annoying as its very very thick. Also didn't like the feel of the shifts when the oil was cold so he went with a 75w90 oil for the cold months and no issues.

COST OF THE 6 SPEED SWAP

SIMPLE SETUP

With a simple basic setup either getting a p12 trans or even cheaper getting a Spec V trans and doing the work yourself to swap the parts over to a p12 bellhousing your looking at a median price of around $2,000 to do the conversion. Using the OEM P12 clutch and flywheel as well as keeping your b13 hubs and having DSS punch them out. This is doing everything yourself.

BETTER SETUP

If your looking into using the aftermarket flywheel and clutch setup but still using B13 hubs having DSS punch them out you will be looking more in the range of $2500-$2800 for the swap.

EXTRAVAGANT SETUP

Example of this would be Coheed and going all out with the Brembo Brakes, B15 rear subframe and brakes and so on. Your looking at a price range of about $3000-$3700

The key is to pick what you want the first time around. I priced these out using a Median Price of the prices listed. You can possibly do it for significantly cheaper if you wait for deals on parts and find the best possible deals, such as people selling used or new parts for cheaper than what you would pay for them new from the manufacturer and having a hookup at a salvage yard. If anyone has any more key information for this thread please feel free to chime in with pics and what was done and Ill add it to the necessary section. I believe I covered pretty much everything needed for the swap and should answer any questions someone has. If you know of any other parts out there for the conversion that work or may work better please feel free to post.

RESULTS

MILES AND NUMBERS

In closing, the numbers don't like. There hasn't been a Spec V guy or anyone that has done the swap yet that has broken one of these 6 speed transmissions gear wise. Like I said, the early 02-03 Spec V transmissions were known to have syncro problems when abused hard. The later models were revised. Power wise, these transmissions should hold 500+whp on a daily basis on street tires with no issues whatsoever for a very long time. Coheed put thousands upon thousands of miles on his at 470whp or so daily and 500+ whp on occasions with no problems. Mine took anywhere from 600+ whp and about 9 drag passes, then 716whp dyno pulls and some street pulls all the way 3rd to almost 9200 rpm in 5th with and three 10 second passes one right at 150mph trap with no issues even no lift shifting on a couple of them. Tried out the no lift shift via AEM on the street on radials with no issues. Several others on here have had no issues with their swaps as well taking 600+ whp on the dyno and thousands of miles on the street. If you all know Coheed, he drives his car hard. His 5 broken p11 transmission gearstacks prove that and he has yet to break anything on this 6 speed.

This is by far one of the best things available for our cars. The more people that take advantage of it and do the swap the more parts will become available making it cheaper and easier to do. This is what we want and that's how things work.

Again feel free to comment and add anything you think would be of value to the writeup.

Ill leave you with this:

[/QUOTE]

[/QUOTE]

OVERVIEW

We all know the weakness of the b13/b14/b15/p10/p11 transmissions. While the b13/b14 transmission is known for its smooth feel and shifting it is plagued with brittle weak gears and a brittle weak case that tends to crack under even slight wheel hop or hard launches. 3rd and 4th gear like to break with anything more than about 350whp or so and hard use. While you can do things to prolong the life of the transmission like cryro treating the gears and case and using a heavy weight gear oil as I like to do, such as 85w140 Valvoline Conventional and Durablend, which I've had great results with extending the life of the gearbox 4-5X than without at roughly 460-550whp ranges.

The p11 and B15 transmissions while they have a stronger case and slightly stronger gears due to added size and tooth profiles and benefit from changes such as having bearings on both the input and mainshaft at the back half of the case to help keep the gears from spreading causing sheering of the teeth are still known to still break in the 400+whp range with hard use. They are also not as smooth as the earlier transmissions due to the changes in how the shift rod, actuating, and forks are mounted and controlled. They tend to want to lock you out under quick shifts and especially no lift shifts usually into 2nd and 3rd gear.

The Ultimate solution to all of our transmission problems is the use of the P12/02-06 Spec V/ 02-06 Maxima transmissions/gearsets. These transmissions are known for their much larger diameter and thicker gears along with a much deeper tooth profile. I have yet to see one of these break in fwd application. The gearset is the same gearset used in the Evo 8/9 MR 6 speed and the Evo guys are known to break 4th gear at 500+awhp and hard use. You also have to take into account the street tires, awd, and 3000+ lb weight of the Evo. The fwd application will put much less stress on the gears. Coheed ran his at 450+whp daily and over 500+ on occasions with zero issues. So far mine has held up between 600-716whp both on the street and multiple drag passes with no issues. You benefit also from the added 6th gear which in the 03+spec V transmissions will result in roughly 950-1000 rpm less at highway cruising speeds vs a b13 transmission which should greatly help pick up some MPG's.

This thread will go over all the parts you can use to complete the swap, price ranges both new and used for the parts, details on installation, and results for different setups.

PARTS REQUIRED FOR THE SWAP ALSO FOR DIFFERENT POWER RANGES AND APPLICATIONS

TRANSMISSION CHOICES

First thing in the swap is choosing which transmission/gearset is right for your application. If you need help finding what year the transmission is, well its a good thing all these transmissions come with a VIN plate attached on the gearbox. 10th character of the vin will give you the year. Or just plug it into something like carfax or autocheck and it will give you the year and model it came from. You can even pull a history report and see what mileage was on it and what happened if you so desired. I did it with mine as I had an extra carfax report I wasn't going to use. Turns out mine was very low mileage and car was in a rear end collision. Good stuff.

The p12 gearbox while would be the easiest and cheapest route with a price range used from $800-$1200 depending on mileage and it already has the correct bellhousing on it. No need to tear it apart to swap internals into the p12 housing. Downfall of it is that the P12 gearbox does not have HLSD that the Spec V and Maxima gearboxes come with. The HLSD is a huge benefit over the old VLSD of the older boxes. This box has short gearing that is great for N/A applications

Second option is the 02-06 Nissan Sentra SE-R Spec V 6 speed gearbox. All of these boxes have the HLSD Differential. The 02 box has slightly shorter gearing than the 03-06 boxes do. The FD was changed from a 4.4 to 4.1 in 03. (See information below) The 03 is close to the same gearing as the 04+ box with a slightly shorter 6th gear. Also there was some revisions to syncro issues in 03+ boxes that the 02 boxes had. Your best bet is to get the 04+ box which is what I currently use. The 04+ boxes have longer 6th gear which will be good for turbo applications and get the best mileage.. This requires you to swap the internals over to a P12 bellhousing to mate to the SR20 Block. These transmissions can be purchased used from a price range of $300-$500 on average depending on mileage and are very readily available.

02 Spec V gear ratios

3.417

1.944

1.258

.947

.773

.630

R-3.252

Final Drive : 4.429

Gear Ratios 2003 6 Spd Spec V

1st 3.153

2nd 1.944

3rd 1.392

4th 1.055

5th 0.809

6th 0.673

Reverse 3.002

FD: 4.133

04 B15 RS6F51H

1: 3.153

2: 1.944

3: 1.392

4: 1.055

5: 0.809

6: 0.630

R: 3.002

Final: 4.133

Third option is the 02-06 Maxima 6 speed gearbox. All of these boxes have HLSD Differential. It uses the same gears but the 02-03 6 speed benefits from the longest final drive which is a 3.81 vs the normal 4.133 seen in the 03.5+ maxima boxes and the 04+ Spec V boxes.. Estimating about a 1200 rpm drop vs what you would see in 5th gear on a b13 transmission. Again this requires you to to swap internals over to a P12 bellhousing. See below for the actual guide on the parts. There is a split in the years of what transmissions came with what parts. Early 03 came with the 3.8 FD, 03.5 so to say came with a 4.1 FD. All the gears are the same ratios just changes to the final drive.

06/01-12/02 PN 32010-5Y774

Use's Gears

1st 3.153

2nd 1.944

3rd 1.392

4th 1.055

5th .809

6th .630

Rev. 3.002

F/D: 3.81

01/03-08/05

PN's 32010-7Y076 01/03-02/20/04 and 32010-7Y476 02/21/04-08/05

All use the same gears

1: 3.153

2: 1.944

3: 1.392

4: 1.055

5: 0.809

6: 0.630

R: 3.002

Final: 4.133

So as you can see, if you wanted to give yourself the absolute longest gears, use the 02-03 Maxima gearstacks and FD into the P12 bellhousing as well as use the HLSD This would give you a nice long cruising gear.

DISCLAIMER: Mazworx offers engine to transmission adapter plates to bolt the Spec V gearbox onto the SR20 engine but requires you to have the bell housing machined down the width of the adapter plate to fit properly. I dont know anyone who has gone this route yet as its easier to just get the P12 bellhousing which can be purchased from either Mazworx or from Greg at Gspec Performance. Both are vendors on this forum and can be contacted on here or through their sites. Links below:

OEM P12 Transmission Bellhousing - Drivetrain - Mazworx

G Spec Performance

Cost of the bare bellhousing is between $300-$350 brand new.

CLUTCH/FLYWHEEL SETUPS FOR DIFFERENT APPLICATIONS AND POWER GOALS

This section will go over the different clutch/flywheel setups starting from cheapest to most expensive.

1. Cheapest route would be to find a P12 OEM dual mass flywheel and clutch assembly used. While rare you can pick a setup up for $200-$300 or so used. The setup would be fine for those wanting a basic setup for N/A application. However, the dual mass flywheel is for one heavy and two is plagued with noise issues when they are older and worn due to its design. This is a bolt on application and requires no grinding or any modification to fit. You must use the p12 flywheel bolts as they are significantly longer. So make sure to get all the parts necessary. I would guestimate power wise this setup would be good to about 200whp or more. Vadim is currently in the process of taking measurements to make sure the p12 and DOHC 240sx/Altima 225mm clutch is the same and can be used as a replacement clutch for this setup. Stay tuned for updates with measurements and pictures.

2. Gspec Performance 6 speed swap flywheel: Aluminum Flywheel 2.0, Sentra B13,B14,B15 2.0 6 speed swap vvl

Straight from the site, at a cost of $550, this flywheel weighs only 11.9 lbs and uses a 225mm 240sx KA24DE clutch kit which you can get clutches to support pretty much any power range up to about 600-650whp or so using clutches like ACT or Clutch Master units. I believe all clearance issues have been taken care of with the most current line of flywheels. I know Coheed got one of the originals and it required some machining to clear the bellhousing. This is a bolt on application.

3. JWT 6 speed swap flywheel. This flywheel is currently under revision due to clearance issues with the originals that required extensive grinding to clear the bellhousing. The flywheel can use a 240mm and 250mm clutch from a 350z or S15 The clutch clearance also required some grinding as well. Priced at $425 new this also gives you an option for some serious holding capability on the clutches with a very streetable feel due to the large surface area. Clutches that size can hold upwards of 700+whp with a strong enough setup. Contact JWT for more information on the setup.

Jim Wolf Technology website

4. The s15 flywheel/clutch setup is another option. As test fitted by tswii, the measurements come out to the same as the p12 flywheels setup. The clutch to use is either a rwd sr20det clutch which can be found online most places and through pretty much every aftermarket clutch company. The clutch is a 240mm clutch setup. The issue with this setup is that the pressure plate and outer edge of the mating surface hits the starter area on the bellhousing. You would need to grind away approximately 4-5mm or have the pp and flywheel machined down. With this setup you can also use the 89-94 Nissan Maxima Clutch setup which turns out to be the same, only issue with this clutch is that the pressure plate sticks out off the edge of the flywheel requiring more area to be ground down from the bellhousing or to be machined down. Whichever way you choose. Details of the setup can be seen here with the Maxima clutch setup.

http://www.sr20-forum.com/866832-post49.html

I believe if you get a RWD DET clutch setup the pressure plate wont protrude out past the edge of the flywheel so it might be the way to go.

5. The last option is one that I worked directly with Dan at Competition Clutch to design and make a Twin Disk Clutch setup for the swap. Thanks to Andreas Miko for providing the p12 flywheel for measurements. This twin disk flywheel/clutch setup uses a two piece design on the flywheel that extends the mating surface of the clutch out approximately .500" to bring the clutch out where needed. The disks are your normal 240sx twin disk 24 spline 1" input. The setup bolted on with zero issues and a new TOB is provided with the kit. Price is $1250 for the entire setup brand new from Competition Clutch. Link Below: This setup will handle pretty much anything power wise you can throw at it and is meant for drag applications but is also pretty streetable once you get used to it. It is what Im currently running on my car and its proved itself over and over. Very very nice clutch setup. It is a fully balanced setup and ive personally taken the setup to 10K+ RPM revs with no issues. If your looking for the ultimate holding solution and overall one of the cheaper solutions, look no further than this setup.

Products

Pics of the setup below:

For your normal single plate clutch setups your looking at anywhere from $300-$500 new depending on what brand and Stage you go with. Pick your clutch dependant on your power goals.

For the Throwout bearing you would use the p12 or Spec V bearing. I wanna say the 240sx one is similar if not the same as the Spec V. Don't quote me. Others can chime in on which ones they used. For my twin disk setup it came with a new bearing that gets pressed into the Spec V bearing housing. You knock out the old one and press in the new one. It can be done without an actual press. It comes out and goes in pretty easy.

MOTOR MOUNT KITS

The only mount kits I know readily available are the Mazworx mount kits. This is a bolt on application for the b13/b14/p10/b15. The p11 requires modification on the transmission mount in order to do the swap. The kit includes the transmission side mount that bolts to the frame in replacement of the original mount brackets for the 5 speed, the new rear mount bracket, an axle carrier bracket (you must specify DE/VE or DET as they are different) and all the new hardware to mate the p12 transmission to the SR20 as the bolt lengths are different. Link below: Kit is priced at $399

Mazworx QR 6 speed conversion mount kit - Drivetrain - Mazworx

A second option if your lucky enough is to find the p12 transmission mount and it has proved to be a bolt on application as well. You could use either the Mazworx rear mount or make your own and use the Mazworx carrier or if you have a DE/VE use the p12 axle carrier if your lucky enough to find one.

Pic below of the p12 transmission mount bolted in place on a b13

[/QUOTE]

[/QUOTE]HYDRAULIC CLUTCH CONVERSION FOR B13/B14/P10

For those of us without a P11 or B15 we are required to convert the clutch to hydraulic as the p12/SpecV transmissions use hydraulically actuated clutch forks.

There are a couple ways to go about this procedure. There is the use of the b15 clutch and pedal setup. This requires modification to the pedal and firewall to get the pedal to sit properly. All the install of the b15 pedal and clutch master cylinder can be seen here:

http://www.sr20-forum.com/turbo/23692-converted-clutch-b15-hydro-setup.html

I have done 3 conversions this way using the b15 pedal assembly and all are working perfectly. Its difficult to get the pedal to line up in the old clutch pedal position but if you take your time it can be close enough that you won't be able to tell.

The next way and so far the easiest and simplest way is using a 4th gen (94-99) Maxima clutch pedal and master cylinder assembly. On a b13 its a bolt in affair, no cutting, no redrilling, and no modifying for the upper securing bolt. On a b14 it requires modification to weld a new tab for the upper mounting bolt. Pretty simple. It bolts in and aligns the pedal perfectly to the old position. Just mark where the new tab needs to go and then weld one on and done. You have to notch the ridge on the firewall where the master cylinder reservoir will hit to allow clearance. Here is Manny's install of his Maxima pedal. Thanks again for the information.

http://www.sr20-forum.com/862864-post253.html

For the p10 guys I believe it applies the same as the b14 guys. Ive also heard through the grape vine that a p11 clutch pedal assembly might work just as well. Again haven't had anyone confirm and I will update as more information comes in.

Price wise, you should be able to pick up the pedal, clutch master cylinder, and line to the slave cylinder for under $200. You can use any year b15 pedal assembly, doesnt matter if its the Spec V or the 1.8L. Its all the same. Same with the 4th gen maxima setup. If you look around you can find deals on these parts. I usually get mine between $75-$100 for the whole setup.

As for the second half of the conversion, the slave cylinder. So far only two slave cylinders are known to work. The p12 and GTIR. Both are at times hard to find but Greg V and Mazworx are the known suppliers for them.

OEM P12 Slave Cylinder - Drivetrain - Mazworx

Slave cylinder is priced at $40

SHIFTER AND CABLE ASSEMBLY

Part of the conversion requires ditching the old school shifter assembly that uses a arm and stabalizer that attaches to the shift rod on the transmission. The 6 speed uses a cable actuated shift mechanism. The shifter is a solid box mounted inside of the vehicle (preferably) and cables that go to the transmission and secure to the shift actuator assembly on top of the trans. The cables are held onto the trans via a bracket with U-Clips. Make sure to get the transmission side bracket with the transmission along with the clips. You can use the p12/Spec V/5 speed manual QR25 Altima/6 speed Maxima bracket. It all mounts the same.

Couple different shifter/cable assemblies you can use.

First one is the Spec V shifter assembly which Manny is currently using. It is a bit more low profile of the other choices and works well. Here is Mannys install of it.

http://www.sr20-forum.com/members-rides/53664-manny-s-b14-same-book-different-chapter-update-4-14-2013-a-6.html#post862422

The second option is using a 5 speed QR25 Altima shifter assembly and cables. The difference is its not quite as low profile as the spec v but you can cut the excess off (mounting points for the Altima console) and make it pretty low profile. Good thing about this assembly is that the rear bolts line up perfectly where the shifter bushing bolted to by removing the stud plates. Then redrill front holes and done. It fits cleanly and perfectly. Another difference is the rubber plate on the Altima mounts on the inside of the vehicle. Pics of the Altima shifter assembly mounted below:

Last option is to use the Maxima shifter assembly. It might require more trimming but should fit the same but it is slightly more bulky. Your best bet is to use the Spec V or Altima setup.

Price for shifter assembly with cables used should be $50-$150 I would say depending on the yard. I got my Altima setup for $40 but again I give the yard a lot of business and he knows me so he hooks me up.

AXLES/HUBS/BRAKES

Moving onto the axles, hub, and brake options with this swap. Another added benefit from this swap is the much larger axles including the larger hubs and outer cv joints. These axles are beefy compared to the older axles and should withstand a ton of power and abuse. The axles use a 36mm nut vs the 32mm on the b13/b14. The p10/p11/already have the larger splined hubs and axles so there is no need to swap anything. This is strictly for the b13/b14/b15 guys.

You have a couple options here starting with the cheapest first and something that I worked directly with DriveShaftShop (DSS) to develop and produce with the help of Josh @unijabnx2000 for taking in his hubs and axles.

1. The first option which is by far the cheapest and easiest is to send a set (preferably new) b13/b14 hubs to DSS where they will drill and respline them to the larger spine of the Spec V axles. The cost on this is $100 if you send in BNIB hubs and $150 for used hubs because they require cleaning before machining can be done. This allows you to keep all your current brake and knuckle assembly and is a done deal. You can get a hold of Tad or Frank at DSS at the following link. Just tell them you want the procedure done for the hub to be resplined to the Spec V axles. Simple as that, its a couple day turnaround as well. For you drag guys this allows you to keep your B13 SE-R or NX brakes so you can also run a 13" drag wheel with no issues. A 13" drag wheel will in no way shape or form clear the stock B15 brakes. So this is by far the simplest and easiest option. There should be no reliability issues with this setup and the size of the new splines is comparable to DSS's 5.9 Series Honda axles with the exception of not having Chromoly outer joints. Either way it should handle whatever you can throw at it.

The Driveshaft Shop | Home page

DISCLAIMER: There is one member on here who did the swap and had issues with the driver side axle being too long causing binding of the CV joints which under high hp (above 600whp) they would snap at the midshaft. Happened twice. Although his car is very low as well taking up any compression the axle might have due to it being low. So far neither I nor Coheed have had this issue but our cars are only slightly lowered. A fix for this is to swap the b13 midshaft onto the Spec V inner and outer joint. They use the same spline size. Just swap the 3 roller joint for the inner and then install into the outer joint and done. This will shorten the axle and give that extra compression and should solve any issue.

The next option is to just swap to B15 Spec V (YOU CAN'T USE THE 1.8L or 2.0 B15 HUBS AS THEY ARE DIFFERENT SIZE SPLINES) B15 hub, knuckle, and brake assembly setup. Keep in mind the hubs are 4X114.3 vs the 4X100 so you can either redrill the hubs to 4X100 or get new wheels if you dont have dual bolt pattern wheels. The knuckles are direct bolt in to our cars but you may consider getting an alignment done after completed as Coheed found out the steering alignment will change with the new knuckles. Coheed used the opportunity to swap out his entire setup for a Brembo Spec V setup front and Rear. The b14's can benefit from the B15's superior beam and rear setup vs the B14's as well as so he could use the 4X114.3 bolt pattern all around. The entire procedure can be found here:

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

This is the more expensive and costly way to go. Your probably looking at about $150-$300 for just the regular Spec V B15 brake setup, knuckles, and hubs. If you go with the brembo ones your probably looking at $600-$1000 depending. For the rear beam and brake setup from a B15 your probably looking at $200-$400 depending.

If you decide to go with just the front setup and convert the hubs to 4X100 your probably looking at $50-$75 for a machine shop to redrill the hubs and then the cost of new studs at about $30 for oem or $80 for ARP extended.

As for axles you can use p12 or 02-06 Spec V axles. These are the only ones that will work. You can pick them up used for about $125-$175 for both as well as aftermarket new for a bit more. I found mine low mileage OEM red axles used for $130 shipped for both on Ebay. As most of you know I was successful in doing a hybrid swap with my axles but Im putting this out there now, don't try to follow what I did. I got lucky with the right year and model axle that allowed me to use the B13 outer joint on the passenger axle. Coheed and several others were not soo lucky and wasted a lot of time trying. Thats why I had DSS do this conversion so its straight forward and simple for those not wanting to deal with B15 hub/knuckle swaps.

DETAILED INSTALLATIONS

TRANSMISSION INSTALL/GEARSTACK SWAP

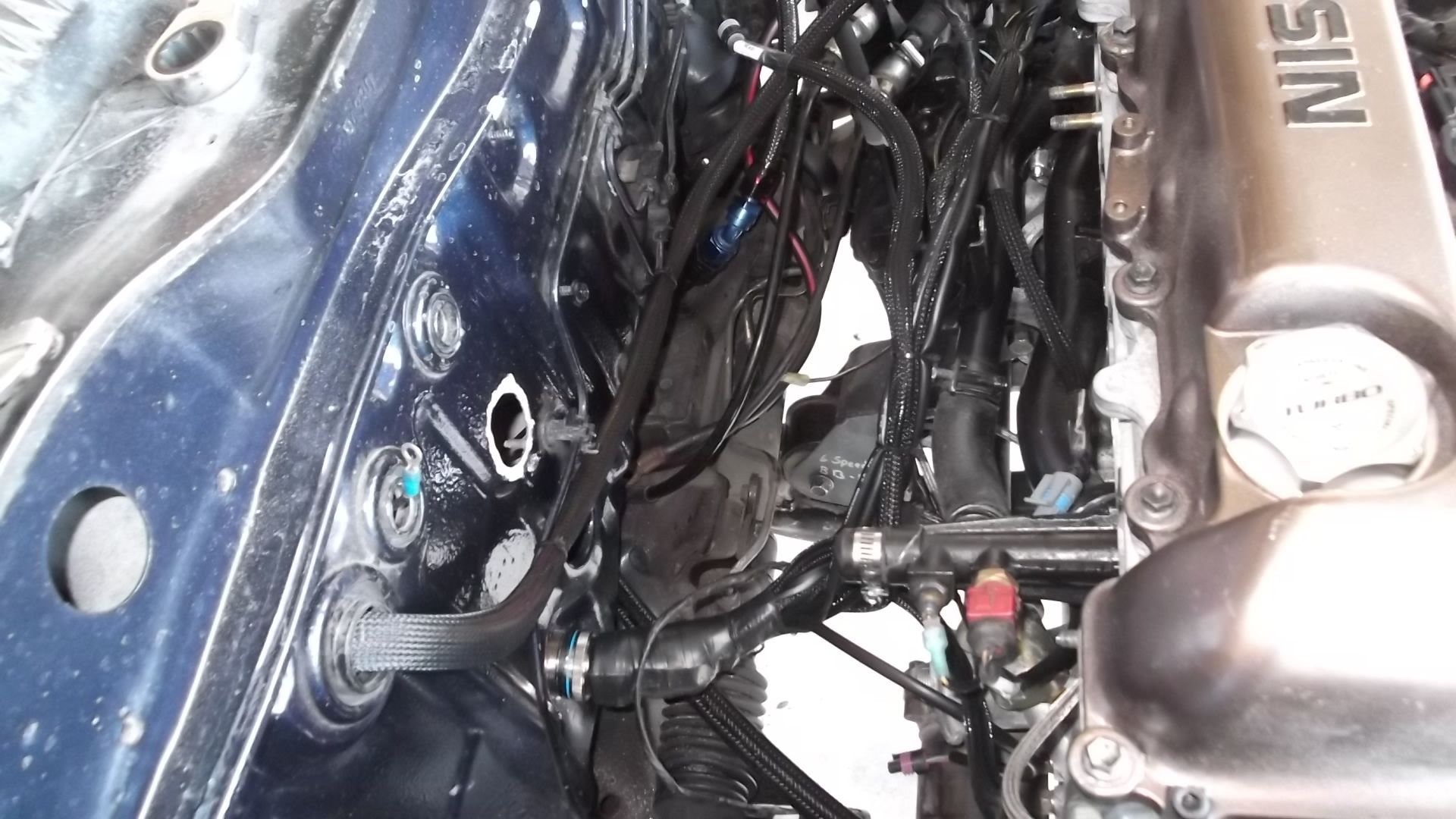

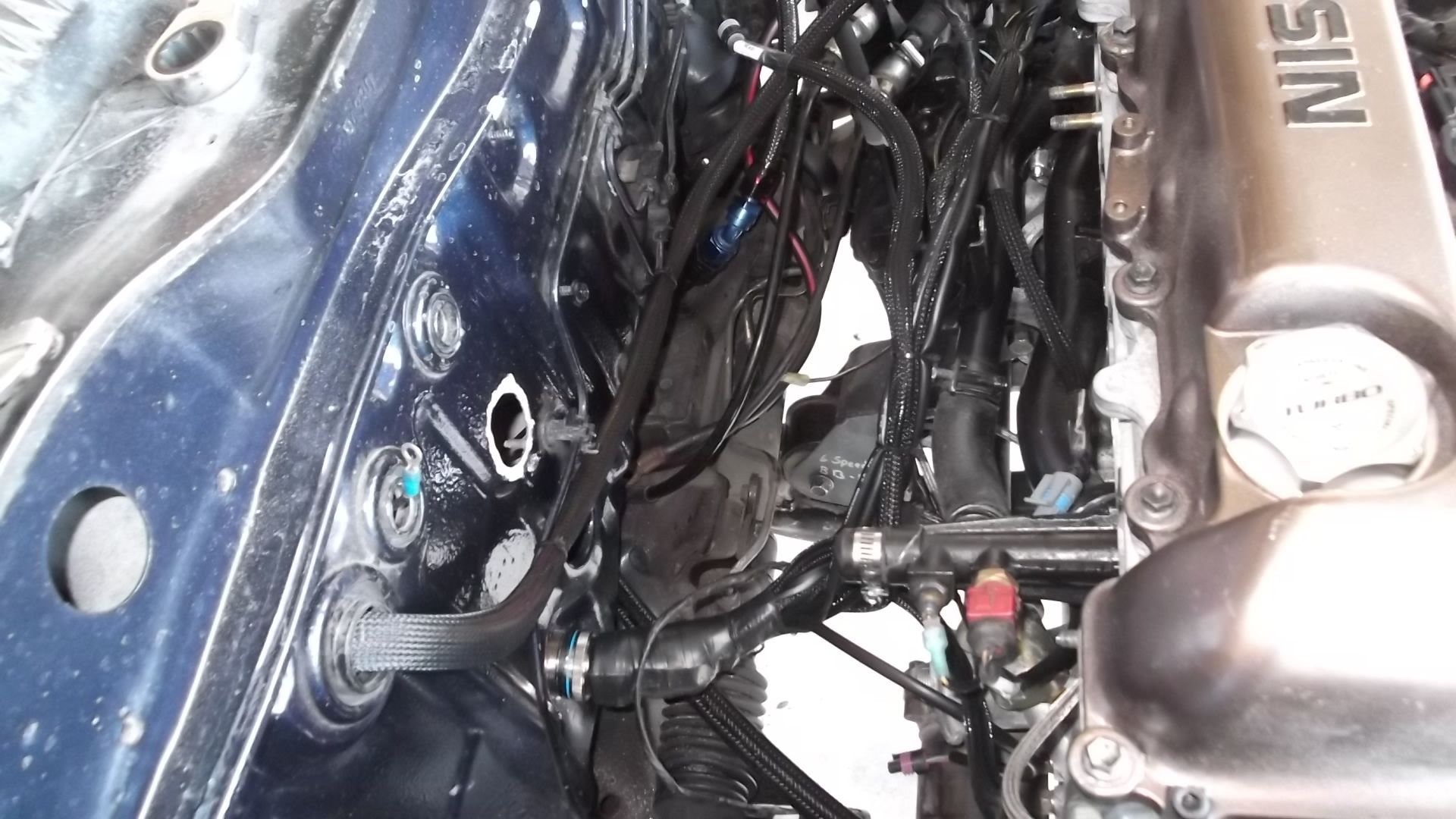

First up is the swapping of the gearstacks to the new/used p12 bellhousing. Its a pretty detailed and lengthy procedure. Coheed has the most intricate write up of anyone so we will be using his. Make sure that when you get your trans to get the new connectors for the reverse and neutral safety switch as they are different. Your reverse switch is the one located on the top of the transmission (blue sensor) the other is the neutral (black sensor)

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

On the transmission installation, if you are making your own custom motor mounts and not using the Mazworx kit, you will need pretty much all new bolts. The starter bolts need to be significantly shorter and the trans to engine bolts need to be significantly longer. The ones provided in the mazworx kit use a 19mm head for the trans to engine bolts and 17mm for the smaller M10 bolts. Thanks to Tswii for doing some measurements. Here is a layout of the bolts needed.

Chrome Bolts, Stainless Steel Bolts, Metric Bolts, Socket Head Cap Screws, Grade 8 Bolts, F911 Bolts for about $15.00 shipped, and they are all grade 12.9 cap head bolts.

[/QUOTE]

[/QUOTE]On my car I didnt swap the subframes so the b13/b14 subframe required notching to clear the much larger differential housing of the transmission. You will see where you need to notch. All you need to cut is the lip portion of the K-member/subframe. You dont need to cut all the way into it like I ended up doing. Cut just enough needed that way you wont have to weld up a filler piece like I had to. The clutch install goes without saying as its pretty straight forward just like any other. Make sure the clutch fork is properly secured to the pivot and TOB before installing the trans. Once up, check to make sure you have proper play in the TOB and that its not tight up against the Pressure Plate. There are two different size pivots, the p12 one and the Spec V one. Dependent on which clutch and clutch fork setup you go with will decide what one you use. I used the longer one with my twin disk setup.

Again here is Coheeds install:

http://www.sr20-forum.com/howtos/45436-how-rs6-6-speed-swap-guide.html

And you can follow manny's install as well:

http://www.sr20-forum.com/members-rides/53664-mannys-b14-same-book-different-chapter-update-12-1-2012-a-15.html

And here is mine, starting with this page and goes for about 2 more pages until its in the car.

http://www.sr20-forum.com/members-rides/29127-9-second-b13-sentra-se-r-build-update-2-26-11-highway-pulls-slicks-26.html

Also with your transmission make sure to use the p12 or Spec V transmission mount bracket that bolts to the transmission. I tried to use the 5 speed Altima one and its a different height. Even though it bolts on, the mount bolt location is higher up which causes the trans to sit significantly lower which wont allow you to bolt up the crossmember. MAKE SURE TO USE THE SPEC V/P12 BRACKET

For you B14 and OBDII P10 guys, the p12 bellhousing has the provision for the crank sensor. It does require you to drill out the provision and tap a hole for the securing bolt. Take your time and everything should work properly with no CEL. The flywheels out I believe all have the 108 tooth profile so again to not trigger a CEL.

[/QUOTE]

[/QUOTE]SHIFTER ASSEMBLY/CENTER CONSOLE

The shifter install is fairly straight forward. Whether your using the Altima shifter or Spec V shifter the install is fairly the same. The shifter assembly fits directly in place of the opening of the old shifter. You can mount it inside the cabin as designed and is the preferred way or you can mount it like I did the first time around and make custom brackets to mount it in the tunnel.

The difference between the two is if you mount it inside you dont have many options out for the console other than custom. You can fit the main part of the center console but the bottom tray and shifter surround will not fit. If you mount it in the tunnel as I did your whole center console will fit with no issues at all. However the shifter will sit very low. I could have mounted mine approximately 1"-2" higher with some trimming to the shifter opening in the tunnel to allow clearance of the shift cable levers. With a custom heat shield you could still run an exhaust in the tunnel as well with no issues if you get it up as high as you can. I had no issues with mine set up like that and it made the interior look stock. The p10/p11/b15 guys dont have this issue as there is plenty of clearance on the console side of things when you mount it inside.

If you go the mounting inside and want to keep it clean, make sure to get the rubber boot that seals the bottom of the shifter assembly and make sure to use the cable passthrough seal and bracket that bolts to the underside or top side if you use the Altima cables of the tunnel to make it nice and clean and sealed. On our cars you will see exactly where the cables need to pass through as there is a plate on the tunnel that you can cut out that would normally be for automatic vehicles where the cable passes through to the outside of the vehicle. You can see several installs here.

My in the tunnel install (B13:

http://www.sr20-forum.com/512687-post475.html

Manny's inside (B14):

http://www.sr20-forum.com/862422-post223.html

http://www.sr20-forum.com/862558-post225.html

My install inside the cabin (B13):

As you can see the rear bolts of the Altima shifter assembly lined up perfectly with the old holes for the mounting studs for the old shifter bushing. Drilled new front holes and installed new bolts.

You want to route the cables up between the subframe/k-member and the firewall directly in the center or if you still have the weight blocks on the b13 to the passenger side of the weight block.

Mount the cables on the trans bracket and secure with the U-Clips as seen here.

Coheed's Shifter install (B14):

http://www.sr20-forum.com/597287-post8.html

You can see the b14 has alot of extra room for the console. Looks like you could easily do a custom boot that would fill in all the gap and look clean.

MOUNT KIT INSTALLATION

The mount kit is pretty straight forward using the Mazworx kit. The new transmission mount bolts directly to the b13/b14/P10 frame using the supplied hardware. For the B15/P11 guys you need to modify it a bit and drill new holes or make a custom tranmission side mount that has the rubber mount on the trans side of things on the frame rail that way you can use the stock mount bracket on the frame. Pics of it mounted onto my B13 below:

The new rear mount bolts to the trans with two 17mm bolts vs 14mm bolts plus using one of the 17mm bolts through the block into the trans. I haven't experienced any issues with mine so far.

Rear mount pictures:

The mazworx axle carrier bracket is a very nice piece although its a two piece design. Coheed had an issue with the bolts that hold the two pieces together coming loose after extended mileage causing major vibration and noise from the axle. Be sure to either remove and loctite the bolts or have the two piece brackets welded together which is what I highly recommend to do. Should look like this when done:

For the trans mount be sure to use the aluminum spacers that come with the kit, one on each side of the mount. You might have to spread the bracket open a bit to get them in but make sure to use them or you might have issues with the mount trying to be pushed through by the bracket. I haven't had any issues with mine but Coheed's car did because none of the spacers were being used.

SPEEDOMETER

For you 93+ guys you can use the electric speedo that comes with the spec V or p12 trans with no issues. For us 92 and below models that use cable speedometers you can swap the speedometer cable drive/speed sensor over to the 6 speed. You need to cut off the tab for the securing bolt as the sensor needs to be rotated clockwise more from its normal location to seat right in the trans. Be careful when installing, one all the way down rotate it until you feel it hit up against something and that should be good. I used the normal bolt with a wide washer to secure mine and had no issues and the speedometer worked like a charm.

GEAR OIL RECOMMENDATION

Just like the B13/B14/B15/P10/P11 transmissions, the manufacturer calls for a 75w90 gear oil. I believe they call for GL-4 oil as well. For those putting heavy use or above 500whp on their cars I highly recommend using Valvoline 85w140 Conventional or Durablend in the trans except for winters in cold areas. Stick to a 75w90 Synthetic. The thicker gear oil is great in this trans. When warmed up it shifts buttery smooth and it will help prolong the life of the gears and bearings and allow it to take more abuse just like it worked in the B13 trans I ran before. I will leave your choice of oil up to you. That is just my recommendation. Coheed first used it as well and liked it but when it started to cool down some it made startups and the first few blocks annoying as its very very thick. Also didn't like the feel of the shifts when the oil was cold so he went with a 75w90 oil for the cold months and no issues.

COST OF THE 6 SPEED SWAP

SIMPLE SETUP

With a simple basic setup either getting a p12 trans or even cheaper getting a Spec V trans and doing the work yourself to swap the parts over to a p12 bellhousing your looking at a median price of around $2,000 to do the conversion. Using the OEM P12 clutch and flywheel as well as keeping your b13 hubs and having DSS punch them out. This is doing everything yourself.

BETTER SETUP

If your looking into using the aftermarket flywheel and clutch setup but still using B13 hubs having DSS punch them out you will be looking more in the range of $2500-$2800 for the swap.

EXTRAVAGANT SETUP

Example of this would be Coheed and going all out with the Brembo Brakes, B15 rear subframe and brakes and so on. Your looking at a price range of about $3000-$3700

The key is to pick what you want the first time around. I priced these out using a Median Price of the prices listed. You can possibly do it for significantly cheaper if you wait for deals on parts and find the best possible deals, such as people selling used or new parts for cheaper than what you would pay for them new from the manufacturer and having a hookup at a salvage yard. If anyone has any more key information for this thread please feel free to chime in with pics and what was done and Ill add it to the necessary section. I believe I covered pretty much everything needed for the swap and should answer any questions someone has. If you know of any other parts out there for the conversion that work or may work better please feel free to post.

RESULTS

MILES AND NUMBERS

In closing, the numbers don't like. There hasn't been a Spec V guy or anyone that has done the swap yet that has broken one of these 6 speed transmissions gear wise. Like I said, the early 02-03 Spec V transmissions were known to have syncro problems when abused hard. The later models were revised. Power wise, these transmissions should hold 500+whp on a daily basis on street tires with no issues whatsoever for a very long time. Coheed put thousands upon thousands of miles on his at 470whp or so daily and 500+ whp on occasions with no problems. Mine took anywhere from 600+ whp and about 9 drag passes, then 716whp dyno pulls and some street pulls all the way 3rd to almost 9200 rpm in 5th with and three 10 second passes one right at 150mph trap with no issues even no lift shifting on a couple of them. Tried out the no lift shift via AEM on the street on radials with no issues. Several others on here have had no issues with their swaps as well taking 600+ whp on the dyno and thousands of miles on the street. If you all know Coheed, he drives his car hard. His 5 broken p11 transmission gearstacks prove that and he has yet to break anything on this 6 speed.

This is by far one of the best things available for our cars. The more people that take advantage of it and do the swap the more parts will become available making it cheaper and easier to do. This is what we want and that's how things work.

Again feel free to comment and add anything you think would be of value to the writeup.

Ill leave you with this:

[/QUOTE]

[/QUOTE]

Last edited by Vadim

on 2013-04-19

at 05-53-39.

, granted paying $1k for P11 trans is not something I plan on doing either!

, granted paying $1k for P11 trans is not something I plan on doing either!

Back to top

Back to top