Gen 2 D2's now, those click when u turn the adjusters vs Gen 1's that didn't

Originally Posted by

aszilagyi

D2 update

I ran a set of D2 struts for Jason Lee.

That are new and improved over the older set I worked on for MicaCeli.

The good news:

There was an adjuster design change. And it is completely functional.

And the range of adjustment (mostly rebound) is large. (a good thing)

Also they added a detent system. Making it easy to count out the adjuster clicks.

The not so good:

The force curves are still craze stiff in compression.

And the seal force is still too high. And has a weird effect seen in the low speed area of the shock plots.

The body cap and bearing has been changed. So I need to make new tools to disassemble the strut. So this slows the repair slightly.

But overall the design changes are positive!

Originally Posted by

aszilagyi

D2 update

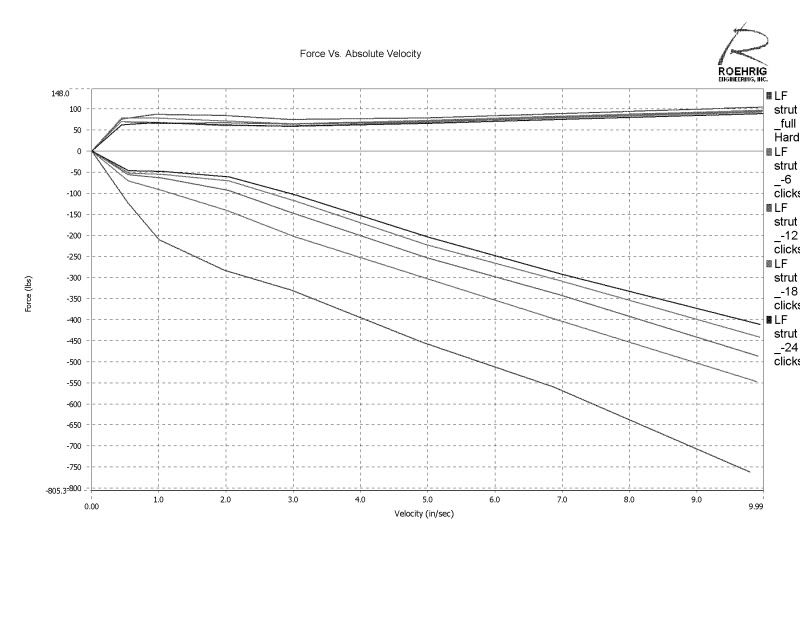

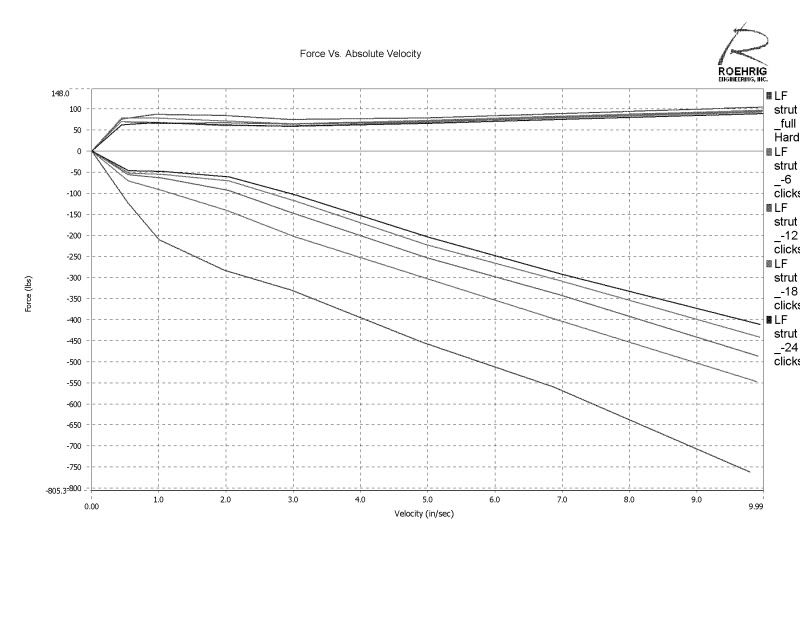

Jason Lee’s LF D2 struts

Shown are runs as delivered from D2

With the adjuster set @:

Full hard

-6 clicks

-12

-18

-24

Originally Posted by

aszilagyi

FYI D2 update

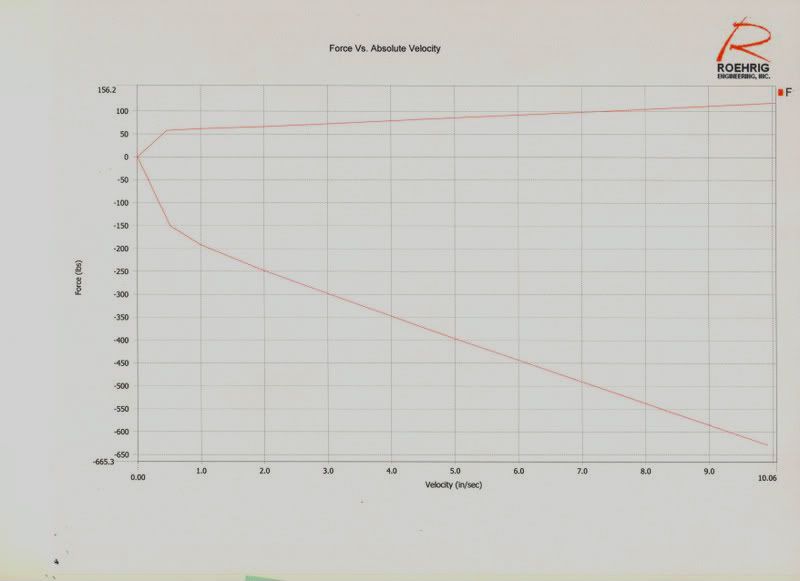

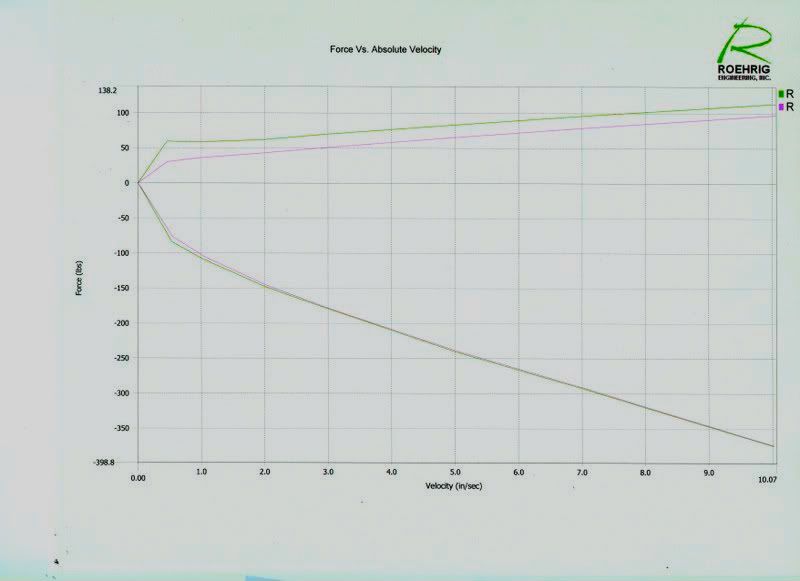

Sadly I am disappointed in the changes made by D2.

After working on a newer set for MRSUPERTWO.

The revisions made to this newer version corrected the non-working adjuster from the earlier version. But for some reason they changed the shaft seal and bearing.

This new shaft seal may add to the durability?

But it also exhibits’ a low speed stick-tion problem. That can not be corrected with out a design change.

I did my best to fix the other problems and re-valve them for Mr. Lee (MRSUPERTWO). And elected not to send him a bill. I feel they will perform better than as delivered new. But I am not happy with the results.

And after a few calls to D2 USA.

I have little confidence they care enough to help fix or even understand the problem.

Its quite sad, they are not interested in using coustomer feedback or support. To better there products.

Link to the OG thread

MR2 Owners Club Message Board

You need to be a member to even see it so I quoted the good stuff from the thread.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.