Originally Posted by

MartinS  Dan - I disagree on the the part between 3k - 4.5k. In my opinion it is an ECU thing.

Dan - I disagree on the the part between 3k - 4.5k. In my opinion it is an ECU thing.

I did a few pulls and got the same result all the time! As I was in a hurry, I could not log ignition and AFR together.

The AFR values for them self explain my thesis quite well...

btw. the engine on this one is BONE stock! no exhaust, intake, etc!

Actually, it also happens @ 5500, and the torque falls like a stone! I can therefore assume that the standard ECU isn't going to be used? The head may also be part of the problem as air speed changes as the rpms climb.

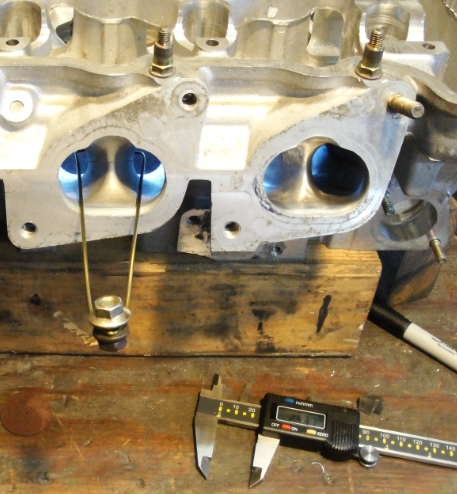

I ALWAYS begin @ the seats and bowls.... ALWAYS. Other porters may, or may not begin this way, I've found that beginning at the seats and bowls will determine the rest of the porting on that cylinder. To begin @ the seats and bowls... one must begin at the valve.... The SR20DE has a 34.25mm intake valve

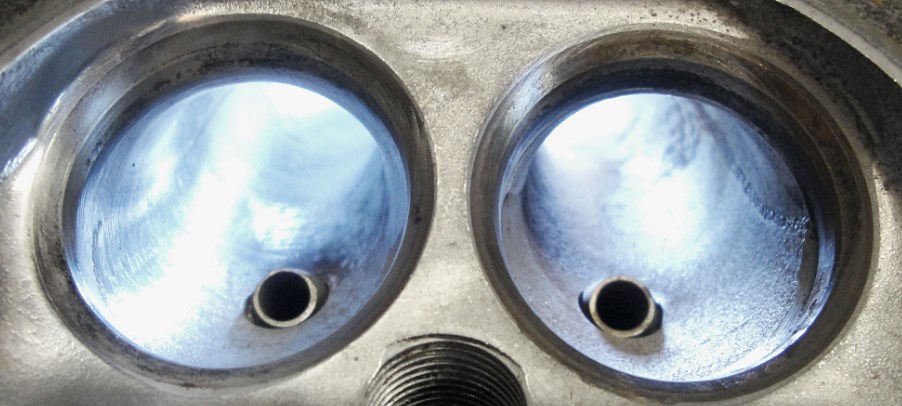

Our valve seat ID measures...

doing the math... the seat bore is almost 86% of the valves diameter. This percentage is very good for a stock set up, typically I try to get the bowl to 85%-90% of the valves diameter to equal the seats bore. So since the seat is in the range, only minimal work will be performed on the seat.

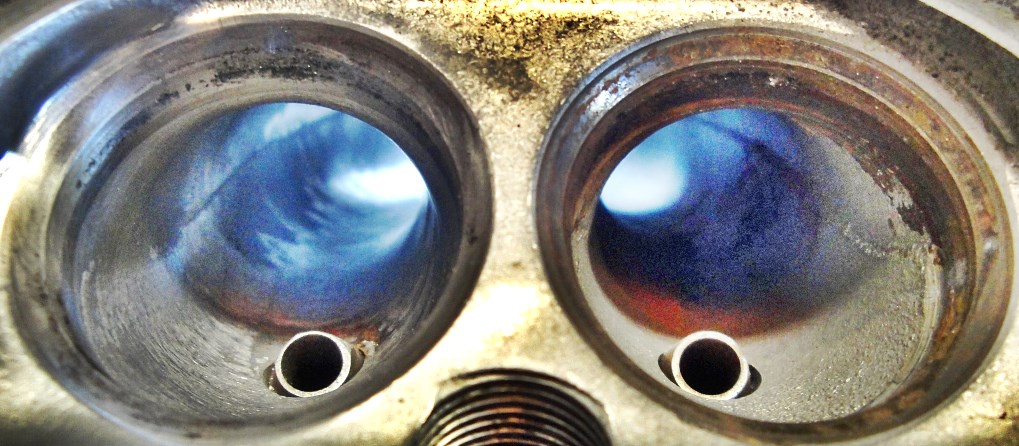

As I begin to work cyl #1(staying within the lines). The very first things I look at is the seat and bowl alignment. This SR20 is far better than a few of the 4AG heads I've worked, SOOOO the focus on the SR20 intake seat/bowl is the short radius....

Originally Posted by

MartinS

A few quotes from his(oldeskewltoy's) side:

Intake:

- Short Radius - the short radius is the only place to easily increase the overall valves draw on the port. A un corrected short radius that interferes can have little or no air flow at lower lift points. This will hurt overall filling of the cylinder, and lower power

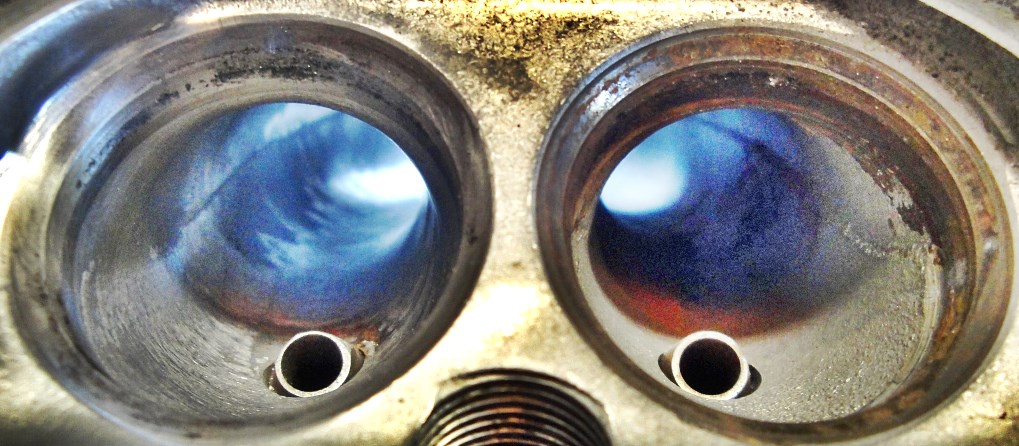

#1 cylinder - Note the protrusion on the bowl on the right(#1 valve), it doesn't have to be a lot, that protrusion you see makes the low lift airflow stagnant because at the valve the air/fuel charge has to navigate a sharp angle. The #2 seat/bowl shows the initial reshaping of the short radius.

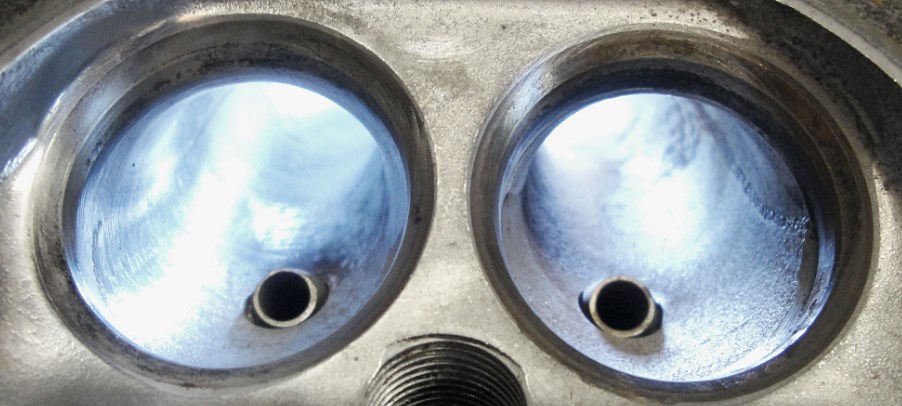

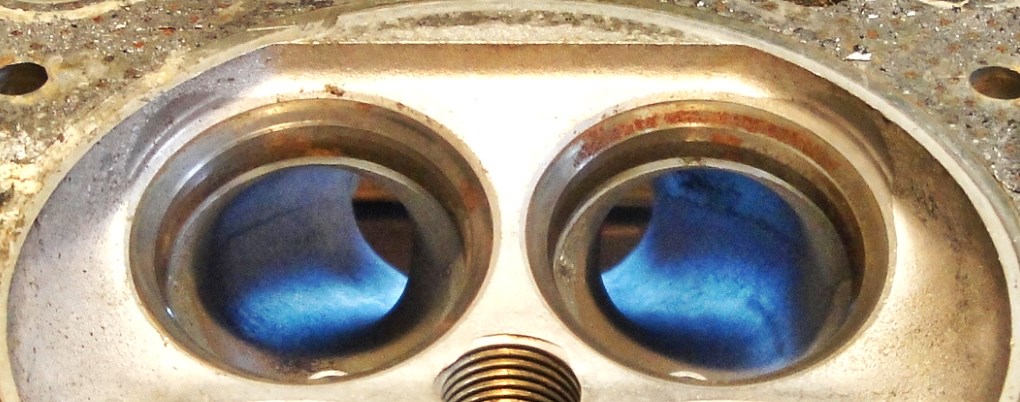

A bit more work in this view, the #2 bowl is showing mild re-shaping to allow more volume. I'm careful to port areas that will "straighten" the angles, or in this case do my best to minimize the bow legged effect. With that in mind note I worked the outside of #2 bowl(far left of bowl on left). This minimizes the angle, that the air/fuel charge has to navigate. A similar, yet not quite as significant amount of material was removed from the inside(right) of the bowl on the left.

A slightly different perspective... showing the overall shape of the bowl and seat transition - the key areas to note in this view are the 3 and 9 positions inside each bowl

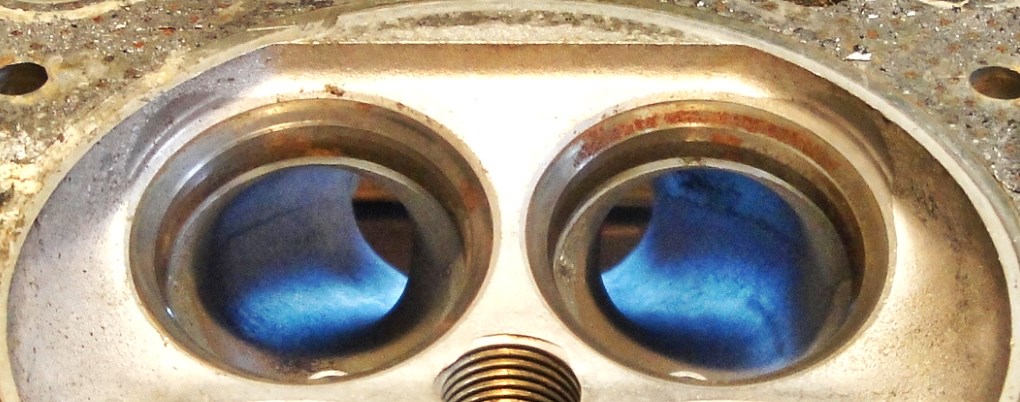

Lets get back to our control... #2 intake bowls, and seats

So what I've done is increased the area around the bowl for the opening valve to draw upon.

More to come........

Be the first to like this post.

Be the first to like this post.

DaveM likes this post.

DaveM likes this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.