uh.... thank you mods/admin.......

As MartinS alluded too... "infotainment" - I'll be discovering what I can with an SR20DE highport cylinder head.

As I alluded too in my introduction....

First... correction, MartinS was owner to OST-008

I've been porting, massaging cylinder head castings for about 5 years. Often times I record these porting jobs.

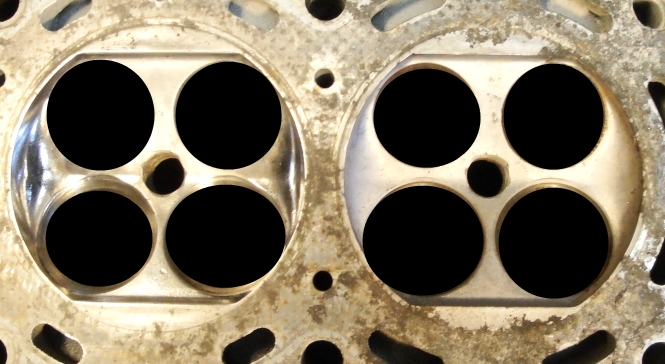

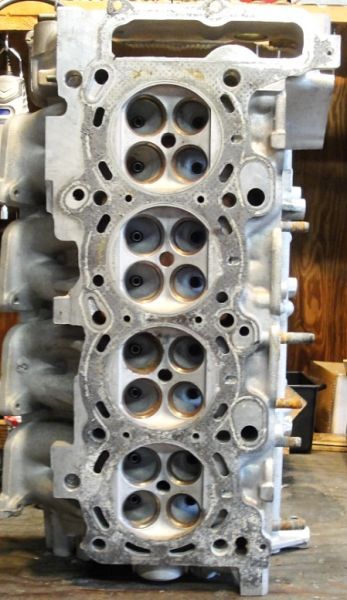

This is my first chance @ an SR20DE head... a highport model This is the condition that I got it in....

NOT a good looking head... and as can easily be seen, this head has spent a fair amount of time wet, and not the good kind either... look at the rust all around

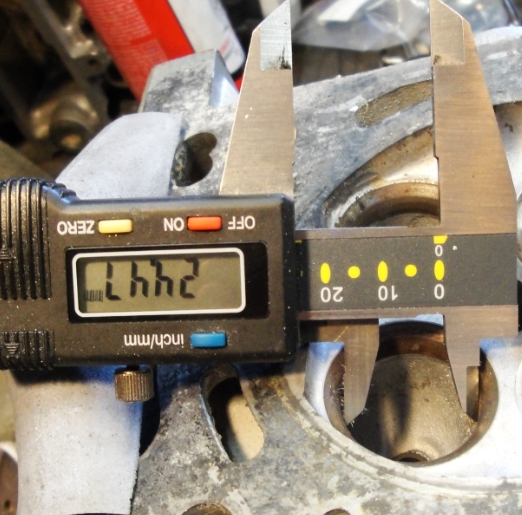

#3 intake bowls/seats....

but a "bath" goes a looong way sometimes...

and sometimes the bath reveals more extensive issues... as in this head, look at the

#1 and

#5 exhaust cam journals. The "rust" you see is embedded into the aluminum, to clean this area up and make it proper again would be a pricey endeavor... so, instead of fixing, lets do a bit of discovery instead...

Initial impressions.... the casting itself is a bit rough, more deburring could be done to the castings, especially the top of the head which holds the cams and valvetrain. The chambers on the other hand appear to be well placed, with very little evidence of edges that would promote detonation (ping). The intake paths are bow legged shaped to allow for the HLA, the intake seat/bowl could use blending to better take advantage of the angled port, and mild short radius. The exhaust bowl/seat is far worse, significantly too small, the port provides little or no room for an adequate short radius, while the splitter, port roof, and narrowing walls are far too intrusive, and appear to truly restrict airflow.

Too begin with... this head is one for discovery.... and as such I'll be performing different porting on 2 of the 4 cylinders, leaving 1 cylinder to use as a control. What do I mean when I say "control", I'll be using my flowbench to monitor any gains, or losses do to my porting work. I'll be leaving

#2 cylinder and its ports completely untouched. I'm leaving

#4 untouched for the time being, but may use it to "assemble" the knowledge I learn from porting

#1 - within the lines, and

#3 - outside the lines.

My flowbench... checking a Toyota 7MGTE head

Originally Posted by

oldeskewltoy

Initial impressions....

1) the casting itself is a bit rough, more deburring could be done to the castings, especially the top of the head which holds the cams and valvetrain.

2) The chambers on the other hand appear to be well placed, with very little evidence of edges that would promote detonation (ping).

3) The intake paths are bow legged shaped to allow for the HLA, the intake seat/bowl could use blending to better take advantage of the angled port, and mild short radius.

4) The exhaust bowl/seat is far worse, significantly too small, the port provides little or no room for an adequate short radius, while the splitter, port roof, and narrowing walls are far too intrusive, and appear to truly restrict airflow.

1 - as I mentioned, the casting is a bit rough leaving many areas containing sharp edges. From my experience, often times poor casting areas lead to sludge build up because the oil and debris sits in these areas "cooking" into place as the miles go by. Making these areas less prone to holding the oil and debris, helps keep the engine cleaner, and easier to shed oil back into the oil pan. A second, and purely selfish purpose is with me constantly changing its position on my porting bench, the roughness really hurts my hands.....

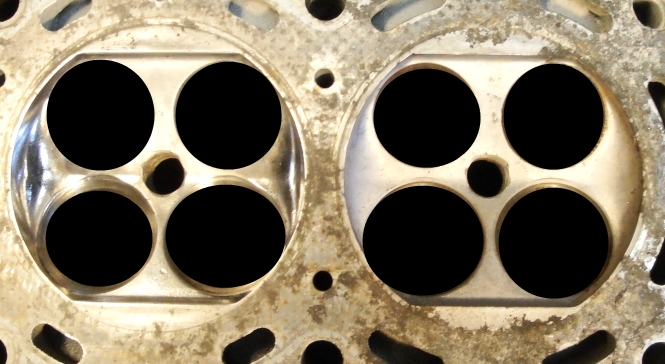

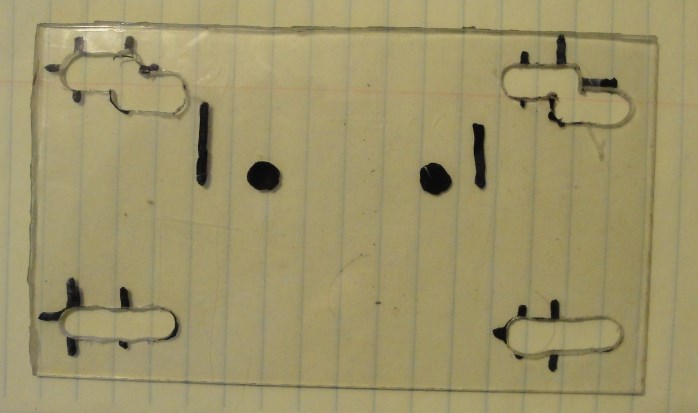

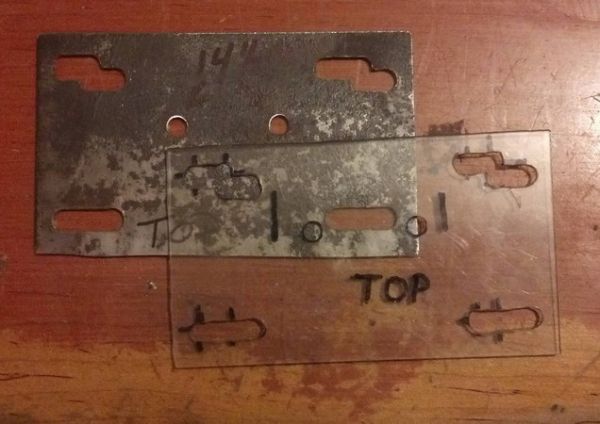

2 - below is a view of the Chambers

#3 and

#4 , I've blacked out the valve openings to avoid distraction....

As you can note, other then doing a tiny bit of blending around the seats, putting a ~.020" radius on both "squish" pads, and polishing the chambers I've had to do very little.

As a comparison here is a small gif showing a 4AGE combustion chamber as it goes from stock, to finished

More to come.....

Be the first to like this post.

Be the first to like this post. .

.

of cylinder head porting :shades:

of cylinder head porting :shades:

Back to top

Back to top