Originally Posted by

HJBarker  My lord, forum resources are just astounding nowadays. This is fantastic!

My lord, forum resources are just astounding nowadays. This is fantastic!

hope this isn't sarcastic... so thank you?? :???:

So why have I not as of yet gotten back with new numbers?? Further development

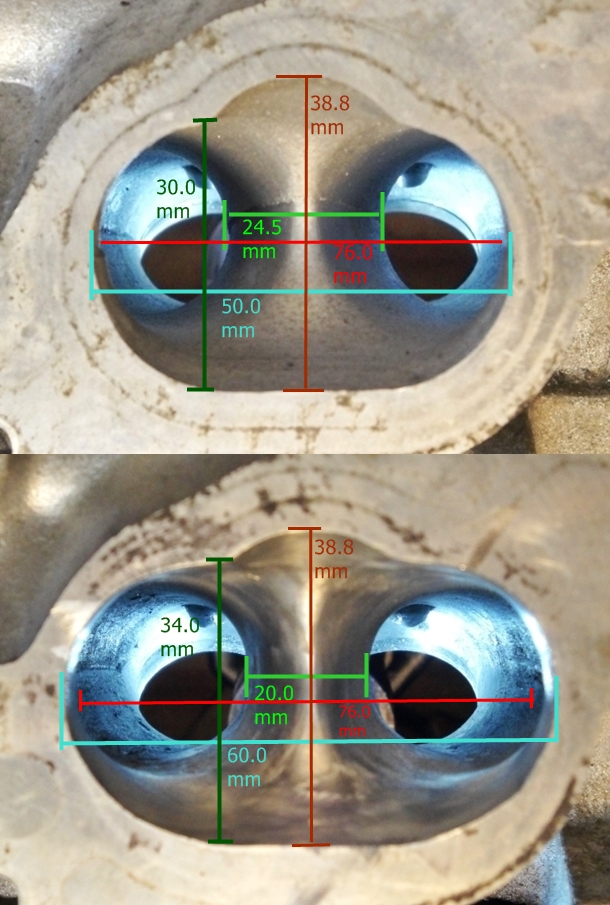

Sometimes perspective helps a lot...... so lets rotate the view we have been looking @ by 90 degrees...

so now with a change of perspective we can better see the problem....

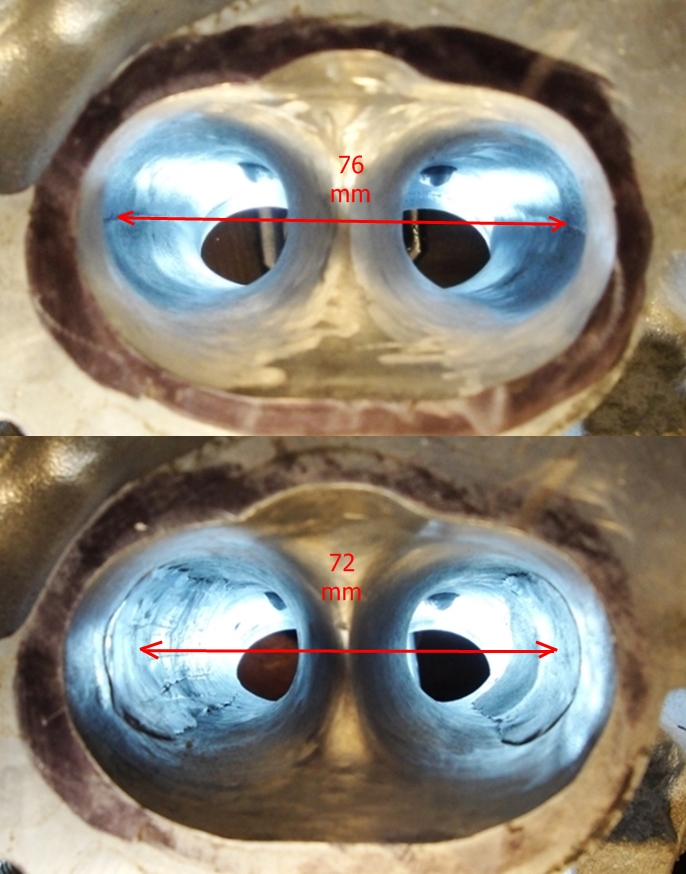

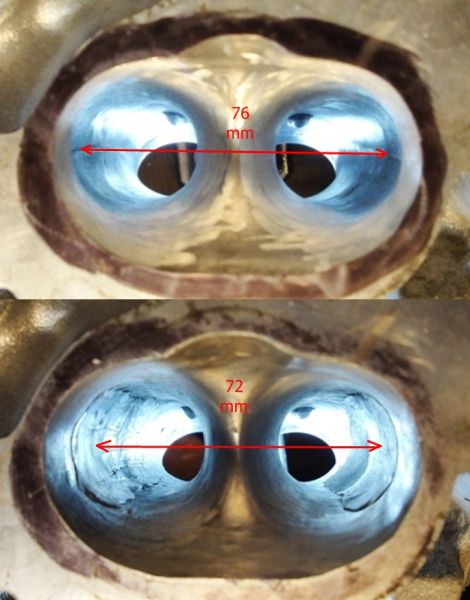

Remember how this thread began????

Well the SR20 head is coming back to where this thread began....

I've decided a more reliable mold, of the width of the port, can be done with the mold making compound, then the clay I used above....

So I mix up some RTV for making molds... and fill #3's outer wall. I'm using a section of rubber to help with making the inner shape.

and the finished piece....

and how it looks installed....

Now that I have the trailing port wall formed, I have to make one for the leading port........

More to come....

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

1fastser likes this post.

1fastser likes this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post.