Yeah, Injector phasing being off 1 tooth is not going to hurt anything. Hell you could have it 180 deg out or 12 teeth out and it will still run just wont have a good idle because the fuel will be spraying way too early.

1 tooth off will be fine, 8-9 is close enough and is what mine was set to.

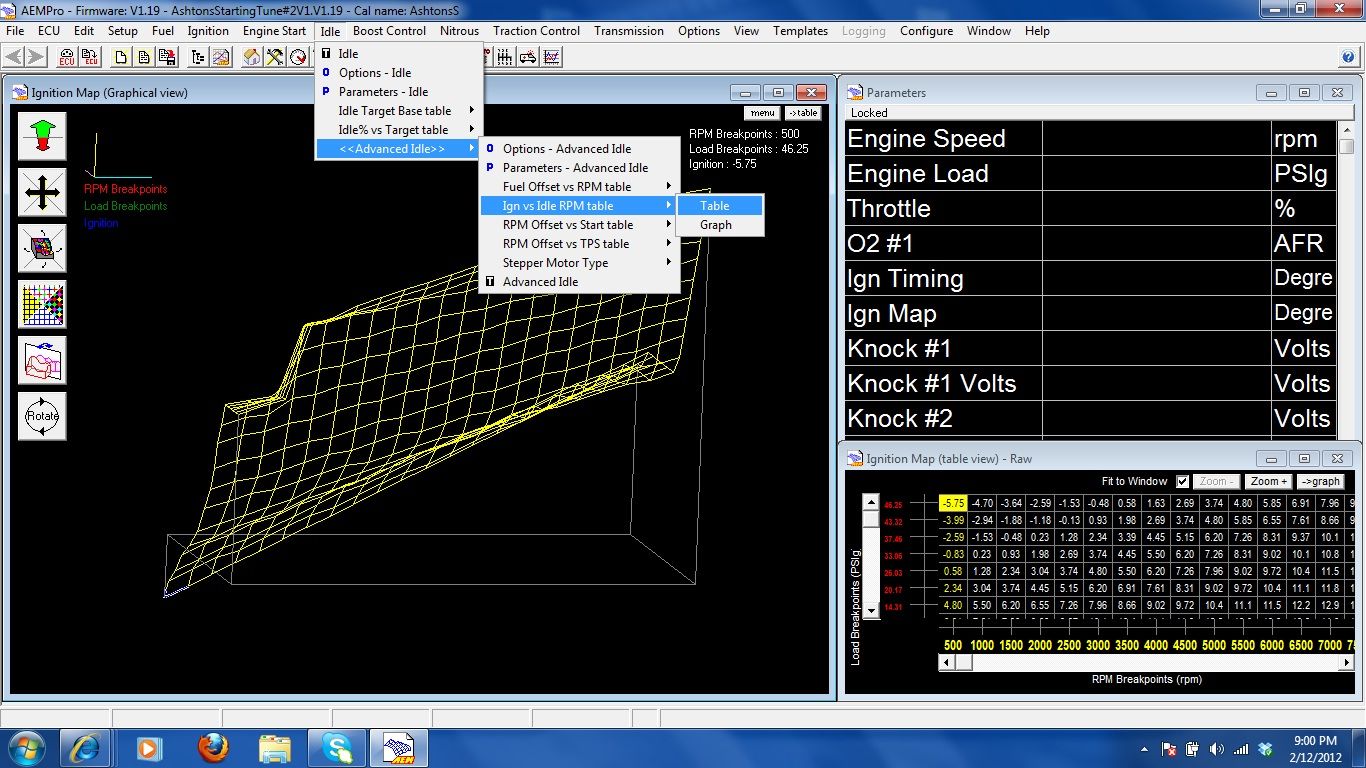

Here is a print screen of the table you need to 0 out. I really dont know why they have this table on there. It makes for a very shitty unstable Idle. I find its much better to have it 0'd so the idle stays where the ignition map is and just set your ignition based on that.

I'll look at the ign vs. rpm table next chance I get to mess with it.

We have the tooth count set to two teeth per Ben's advice. That's what his is set to and his setup is running fine.

I do want to play around with another map I received and check the values.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top