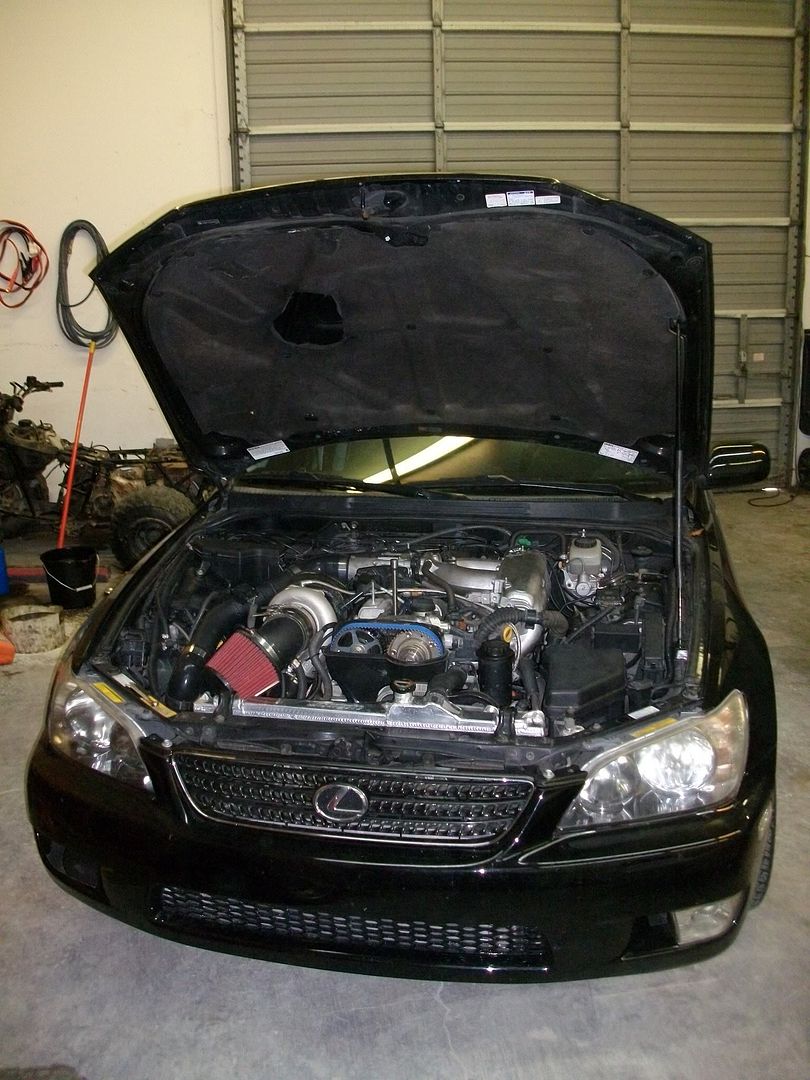

Can you tell what it is now ?

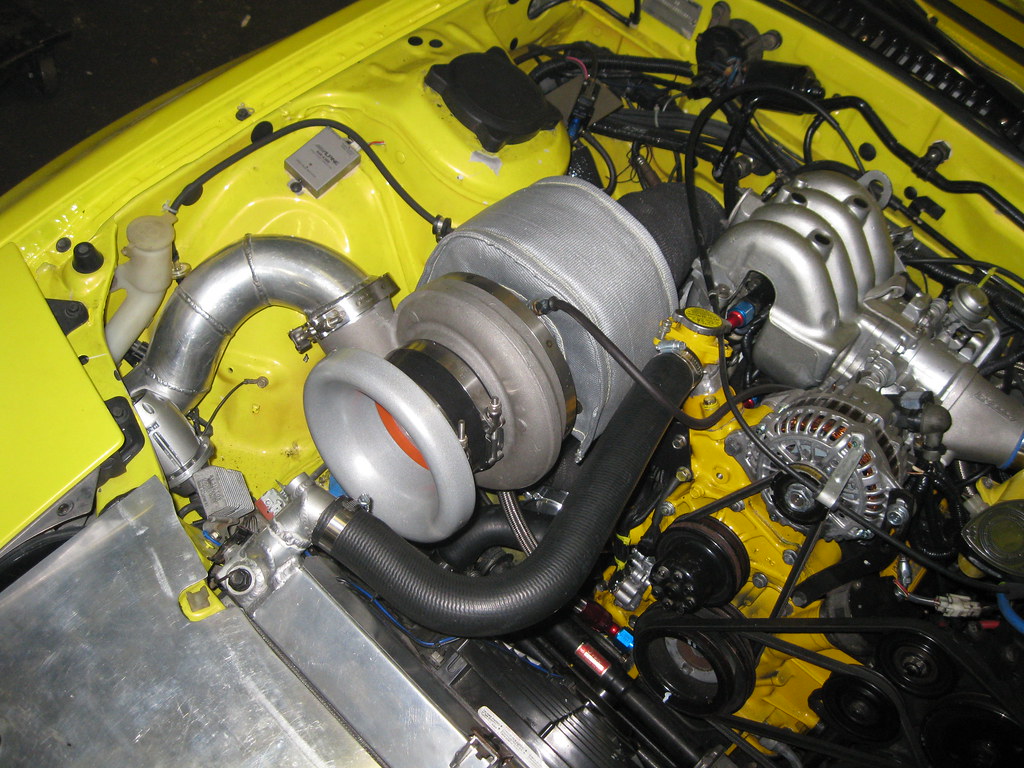

When it was all done

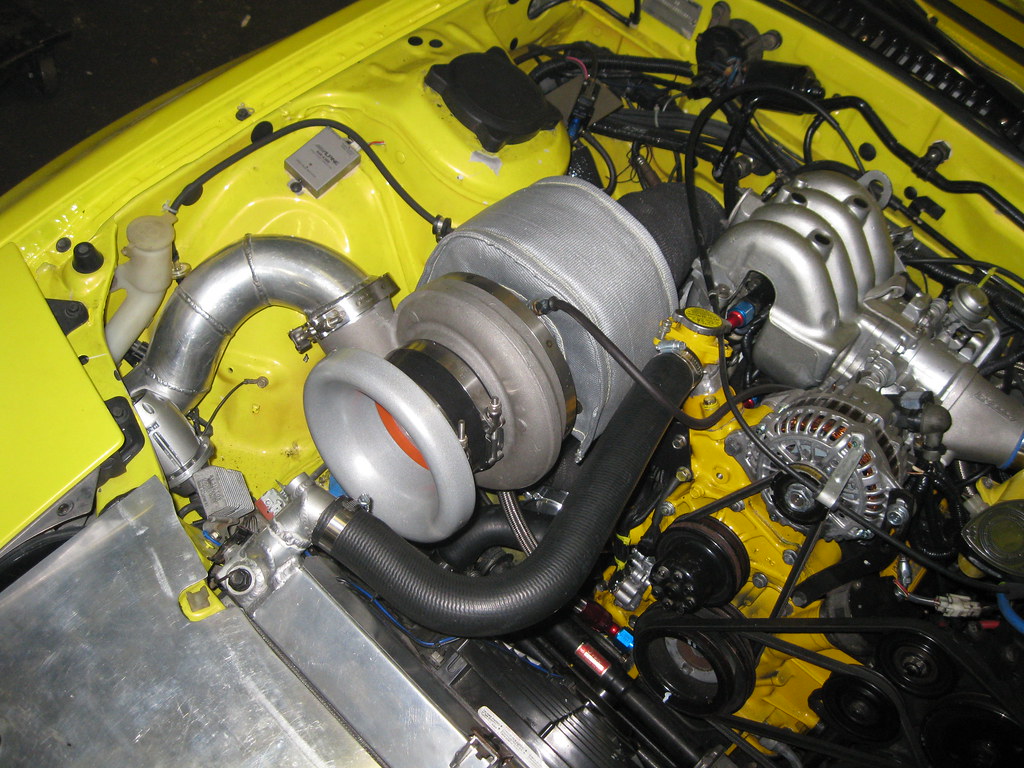

How the S475 sat in the car, wrapped and braced to motor. Pie cut some aluminum, added 3.5" AL vband, did a flare at end of 3.0" pipe to mate up to Vband.

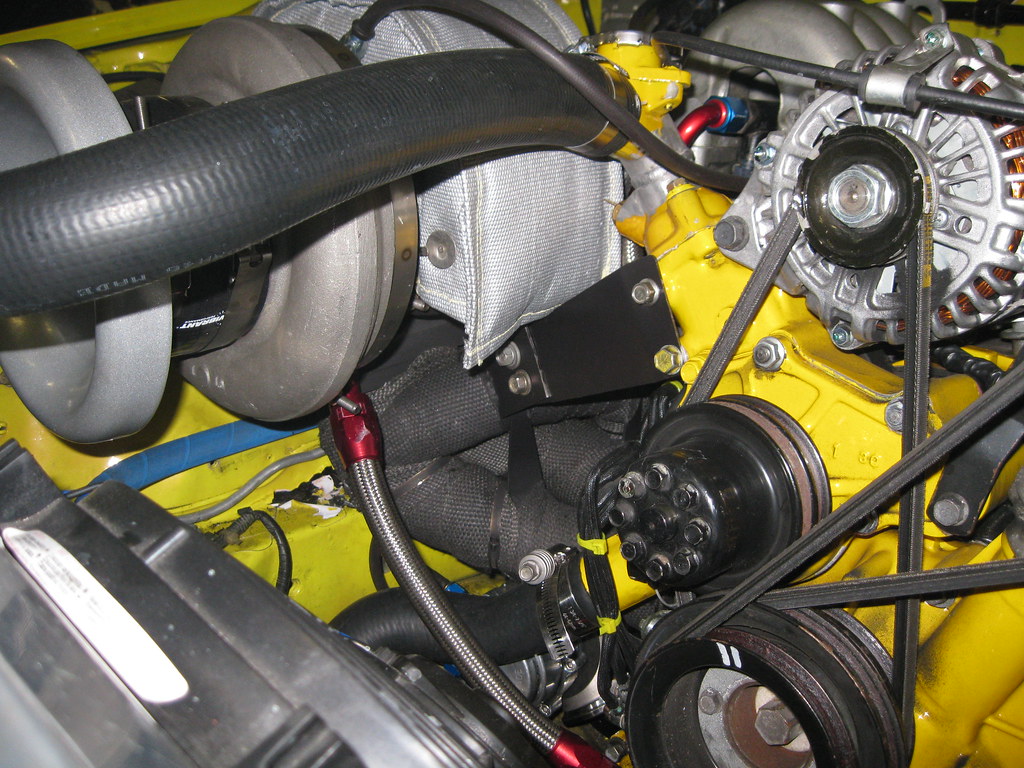

Downpipe, internal welding to smooth transition

Get some perception on how deep the the transition was

When it was all done

How the S475 sat in the car, wrapped and braced to motor. Pie cut some aluminum, added 3.5" AL vband, did a flare at end of 3.0" pipe to mate up to Vband.

Downpipe, internal welding to smooth transition

Get some perception on how deep the the transition was

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top