cut this off the b15 pedal

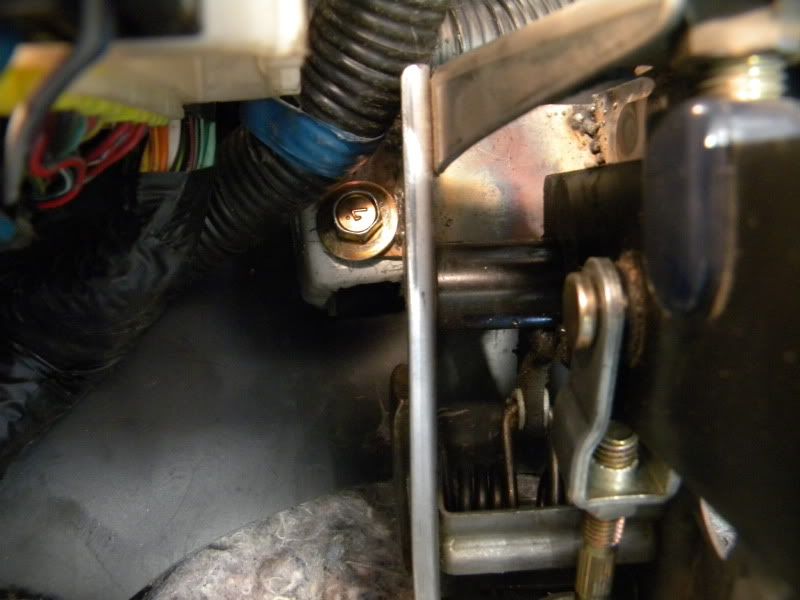

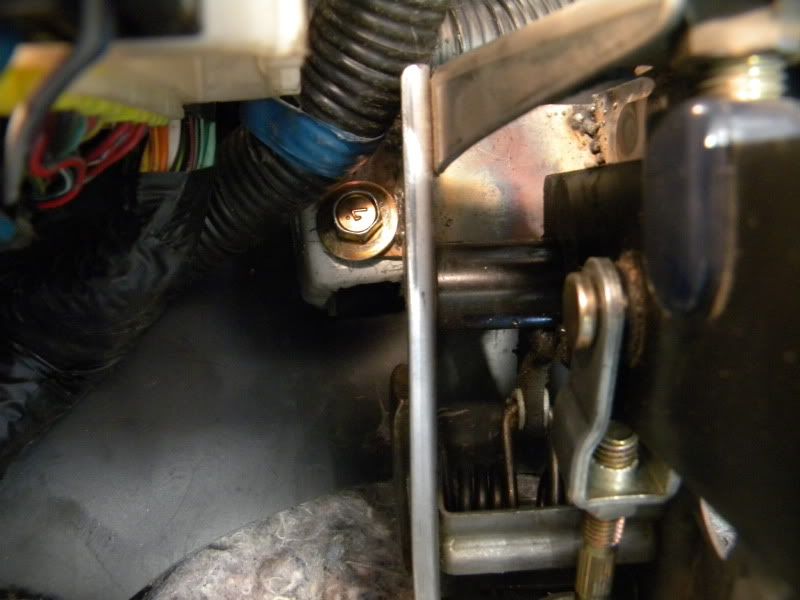

here is how it sat mounted up. You have to drill new holes for the clutch master cylinder to go through to sit the pedal in the right position and line the welded plate up with the upper hole. This will position the pedal right or close.

Here you can see the welded on upper plate which is 1/8" flat steel 2" wide by 3" long

The new holes have to be drilled approximately 30 deg rotated clockwise. You can use the pedal assembly to mark the holes by lining it up where it needs to be and sit correctly and then mark with a sharpie on the firewall. You have to remove the tack welded spacer that sits behind the b13 pedal assembly. You have to cut the left-side spacer off the b15 pedal assembly thats welded onto the surface mating against the firewall. Leave the right-side one as it will allow the pedal to sit straight and not twist when tightening the upper bolt and two nuts down. Make sure to position the opening for the master cylinder to come through correctly as well. If you make it crooked or too high or too low it wont sit straight and bind. Its really not that hard of a job to do. I have very little fab skills and I did the welding and measuring and crap myself. lol.

Here you can see how it sits against the firewall and why i should have left my right-side spacer on. I used exhaust washers to space it out between the firewall and pedal assembly again only on the right side. The left side will sit flush agains the firewall. The firewall is a bit different shape from the b13 to the b15 obviously.

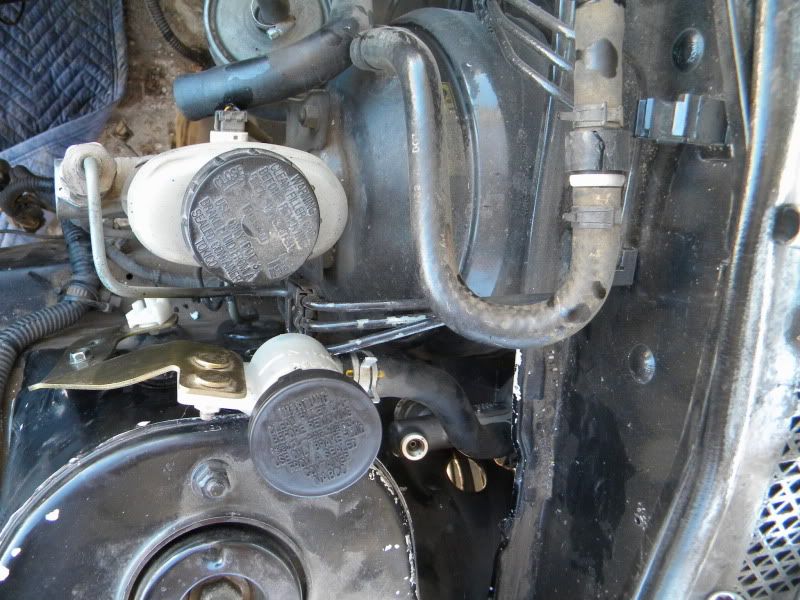

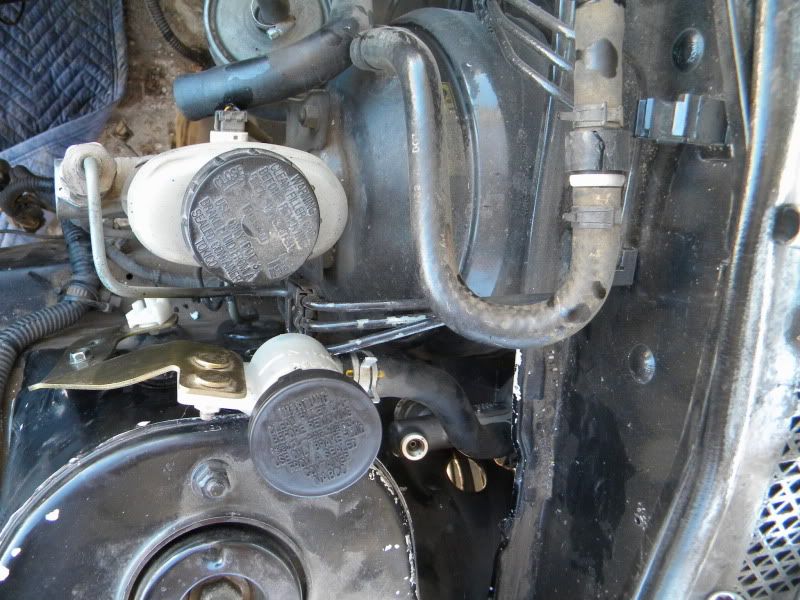

Master cylinder mounted

reservoir mounted

Areal view, lol

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.

Be the first to like this post.

Be the first to like this post. Be the first to like this post.

Be the first to like this post.