Originally Posted by

jagy  What kind of VE springs? Is it direct replacement? Anyone tried that before? Very curious about that.

What kind of VE springs? Is it direct replacement? Anyone tried that before? Very curious about that.

I have never done this before but I have done some research on this in the past as I had once considered everything under the sun for the RR motor.

Using VE dual springs in a RR head

has been done before. If you search the old forum long enough you will find a thread discussing this. I stumbled upon it some time earlier this year or last year. I tried to locate the thread (tonight) but I could not.

Here is what I know/remember from the thread:

The RR valve springs have a

37 mm installed height. The VE springs also have a

37 mm installed height. (Note:

Supertech measures the seat pressure of their VE springs @ 37.3 mm, when installed). The RR are single outer spring/seat while the VE are dual spring/seat. From what I remember from the thread, a little bit of machine work was required for the VE inner spring/seat. I do not recall the specific details.

From a Nissan parts bin perspective, the VE and RR heads use different part numbers for springs, seats, retainers, valves, etc. They only share the same p/n for the collet/keeper. The valve lengths are different and the spring free heights are slightly different as well. There are other minor measured variations as well.

If I stumble across that thread, I will post up a link.

Edit: Just to be clear, the specs given out (the ones I quoted/linked for Roller Rocker) are for USDM Roller Rocker engines. The specs I have posted (for RR engine)

are USDM specifications. I can not confirm that the JDM/UKDM/other Roller Rocker specifications are exactly the same.

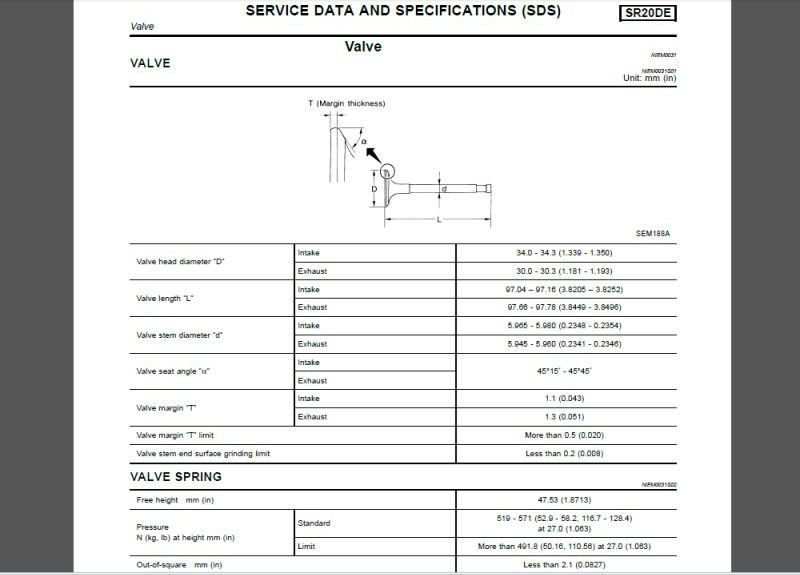

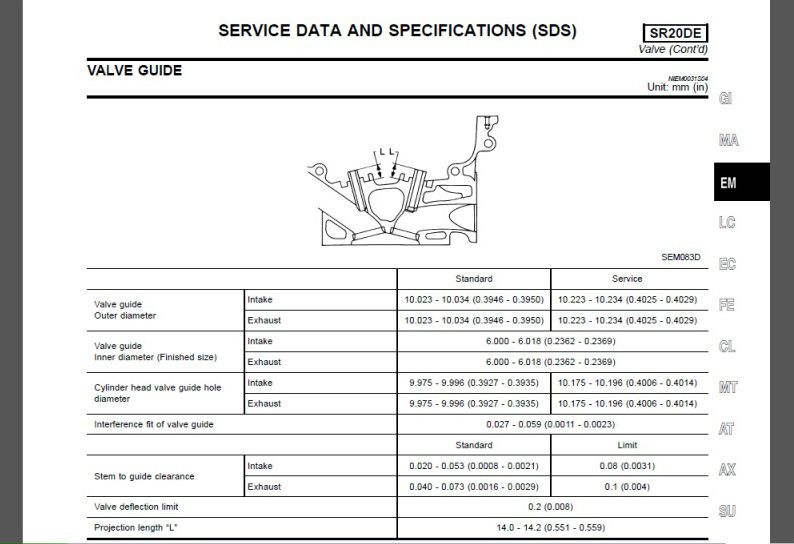

I thought I would add these pictures as a reference tool, just incase somebody was interested.

VE specs (Valves/springs/clearances etc.)

Info obtained from

here.

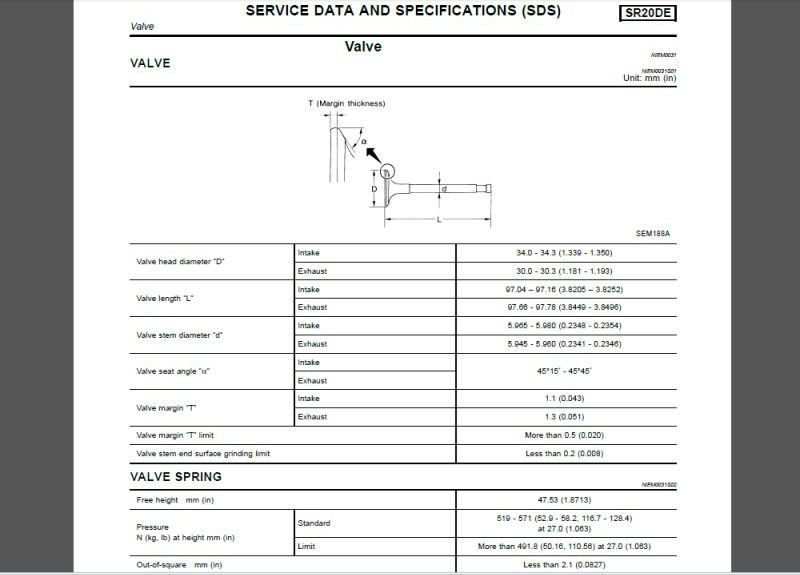

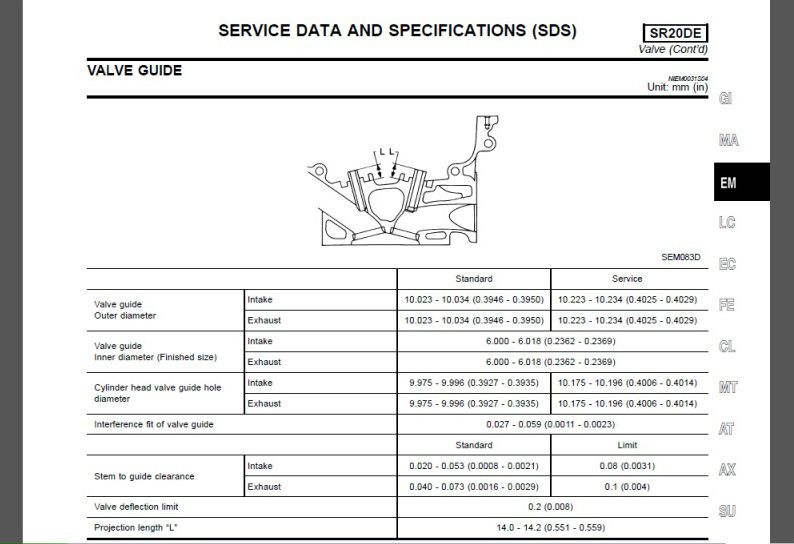

USDM SR20DE RR ('01) (Valves/springs/clearances etc.)

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top