Here are some pics of the conversion of my clutch to hydraulic that way its all set for my P11 trans going in and clutchmasters twin disk. This is my second time doing this conversion. I did one on my buddies 200sx se-r when we put his b15 trans in. The entire hydro clutch setup cost me $60 from mexico pulled from a very low milage 1.8 manual b15.

Removing the old clutch pedal is a sinch. two nuts on the engine bay side and one bolt for the upper support on the pedal, undo the clutch safety switch connector and out it comes.

Next step was i compare the sizes of the pedal assembly to see where the modification needs to be made to best make it fit. The b15 clutch pedal is taller at the top rear part of the pedal assembly and the bolt position for the upper securing bolt is in a different location.

To accomidate i placed the pedals side by side and flush at the faces and saw what i needed to remove from the B15 clutch pedal. Here is the pic of what i had to remove.

Then i took a piece of 1/8" flat steel and cut a piece 2"X3" to weld on the top of where i just cut that piece off. This will be for your upper mounting bolt/upper pedal support. You weld the piece on with the 2" wide running across the upper part of the pedal starting at the rear edge of the pedal where it was cut. The 3" long part runns perpendicular and sticks over the left-side edge of the pedal approx 3/4" or so. This will allow you to line up the pedal and mark where your upper support hole needs to be drilled.

First of all we need to mount the pedal and to do this properly and allow the pedal to sit in the proper postion without bending the pedal or anything like that you will have to drill two new holes in the firewall approximately 30 degrees clockwise rotated from the original bolt hole positons.

But before we can do that we need to get the pedal prepped. There are two circular tabs/spacers that are welded to the face of the b15 pedal that mate against the firewall that need to be removed. You also need to remove the circular guide holes/spacers that are on the firewall of the car. This takes some finessing to get them off. I bent them until broken and then flattened out the part that is tack welded to the firewall. Once you have that done you can drill the holes. Best thing to do would be to place the pedal up into position where it lines up with both the firewall and the upper mounting bolt and where the pedal looks like its in the position you want it. Mark the holes then drill them. This takes some patience as its tough to reach up there on your back and do this while holding the pedal assembly still. haha Very fustrating.

Next after you have drilled the holes you can put the clutch master cylinder through the firewall and then place your clutch pedal assembly up in place and see where the upper support bolt hole needs to be drilled. Its gonna be more towards the front part of the welded piece but kinda eyeball it as best you can.

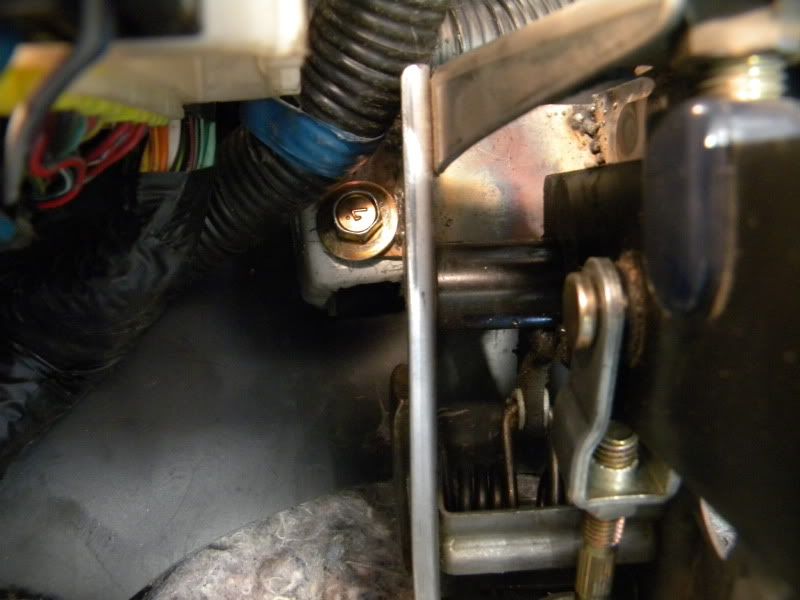

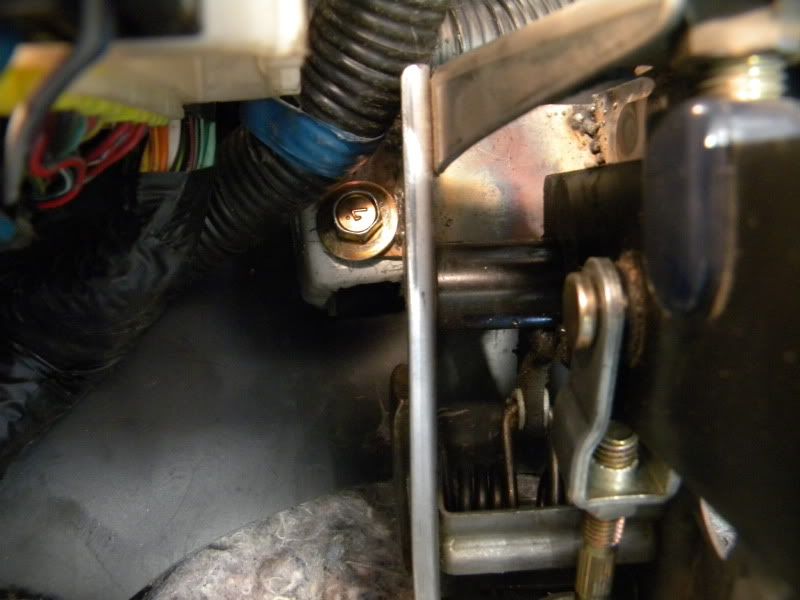

Here is the trick to putting it up, You will need to put about 3/8" of washers on the right side master cylinder stud to go between the firewall and pedal face as the firewalls are at a bit different of an angle. Trust me i fought for 2 hours trying to figure out why my pedal assembly was twisting not allowing the master cylinder to push in without hanging up. Put the pedal assembly up in place and have someone hold the master cylinder on the other side and put the master cylinder push rod clip onto the pedal into positon and secure with the pin to keep it from moving. Then get your upper securing bolt started and do not tighten all the way down, then put the nuts on the pedal to secure it to the firewall and tighten all the way and then lastly tighten the upper bolt down good and then install the clip into the master cylinder rod securing pin.

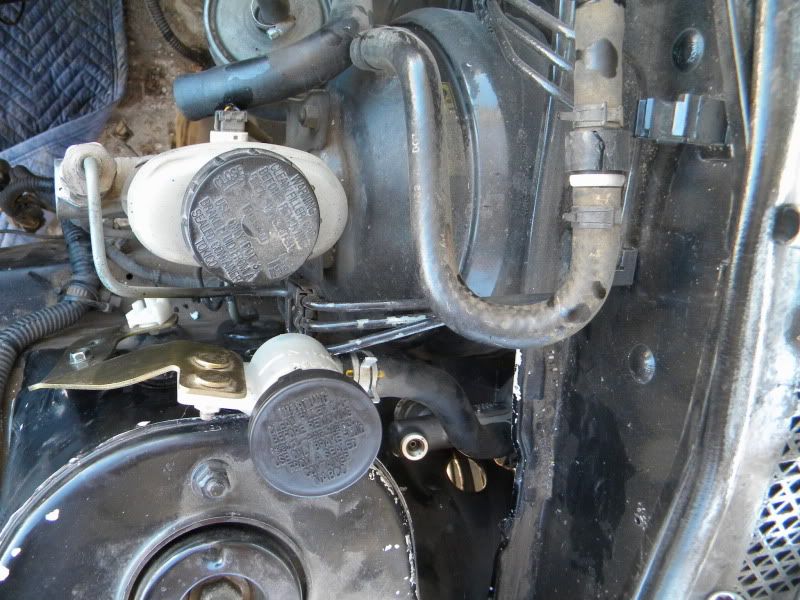

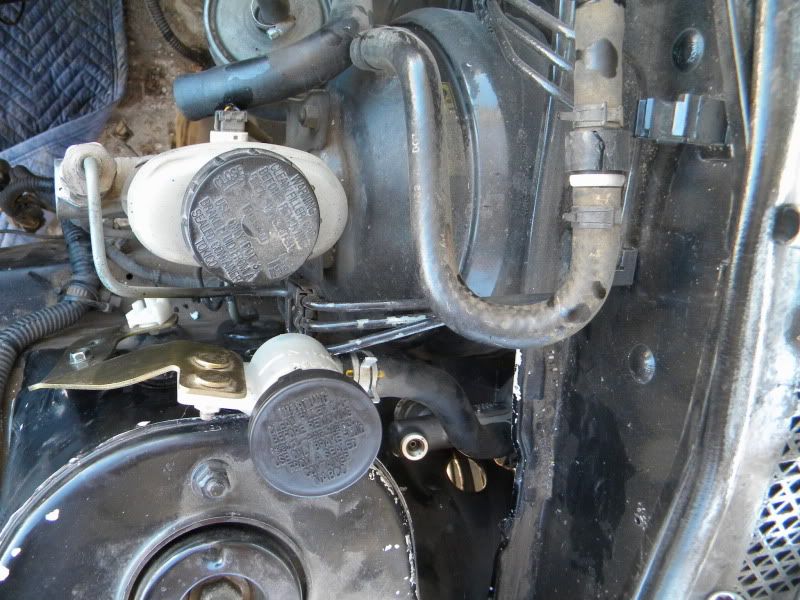

Check the operation of the pedal to make sure its nice and smooth without hanging up. If it does you will need to make adjustments to either your upper securing bolt hole location or your holes on your firewall until it comes out nice and square and allows proper operation. All in all it took me about 3 hours total to do it. Its a lot of back and forth, try this and try that to do it. Then you can mount the fluid reservoir bracket on the strut tower where a black fill plug is located, just remove it and use one of the 10mm bolts with the pedal.

Here are the pics of the outcome and you can kinda see the welded bracket and how it mates against the firewall and where the pedal sits. I lined mine up to where its a little farther away from the brake pedal and for those of you that do road racing this is a good thing to keep you from taping the brakes instead of the clutch or with the clutch. I like it and it came out good and pedal height is perfect.

Thats about all. Its really not that hard and to me its better to do it this way than convert your tranny to cable. You never have to worry about breaking a clutch cable and you can use a heavy clutch and you will never know it.

Removing the old clutch pedal is a sinch. two nuts on the engine bay side and one bolt for the upper support on the pedal, undo the clutch safety switch connector and out it comes.

Next step was i compare the sizes of the pedal assembly to see where the modification needs to be made to best make it fit. The b15 clutch pedal is taller at the top rear part of the pedal assembly and the bolt position for the upper securing bolt is in a different location.

To accomidate i placed the pedals side by side and flush at the faces and saw what i needed to remove from the B15 clutch pedal. Here is the pic of what i had to remove.

Then i took a piece of 1/8" flat steel and cut a piece 2"X3" to weld on the top of where i just cut that piece off. This will be for your upper mounting bolt/upper pedal support. You weld the piece on with the 2" wide running across the upper part of the pedal starting at the rear edge of the pedal where it was cut. The 3" long part runns perpendicular and sticks over the left-side edge of the pedal approx 3/4" or so. This will allow you to line up the pedal and mark where your upper support hole needs to be drilled.

First of all we need to mount the pedal and to do this properly and allow the pedal to sit in the proper postion without bending the pedal or anything like that you will have to drill two new holes in the firewall approximately 30 degrees clockwise rotated from the original bolt hole positons.

But before we can do that we need to get the pedal prepped. There are two circular tabs/spacers that are welded to the face of the b15 pedal that mate against the firewall that need to be removed. You also need to remove the circular guide holes/spacers that are on the firewall of the car. This takes some finessing to get them off. I bent them until broken and then flattened out the part that is tack welded to the firewall. Once you have that done you can drill the holes. Best thing to do would be to place the pedal up into position where it lines up with both the firewall and the upper mounting bolt and where the pedal looks like its in the position you want it. Mark the holes then drill them. This takes some patience as its tough to reach up there on your back and do this while holding the pedal assembly still. haha Very fustrating.

Next after you have drilled the holes you can put the clutch master cylinder through the firewall and then place your clutch pedal assembly up in place and see where the upper support bolt hole needs to be drilled. Its gonna be more towards the front part of the welded piece but kinda eyeball it as best you can.

Here is the trick to putting it up, You will need to put about 3/8" of washers on the right side master cylinder stud to go between the firewall and pedal face as the firewalls are at a bit different of an angle. Trust me i fought for 2 hours trying to figure out why my pedal assembly was twisting not allowing the master cylinder to push in without hanging up. Put the pedal assembly up in place and have someone hold the master cylinder on the other side and put the master cylinder push rod clip onto the pedal into positon and secure with the pin to keep it from moving. Then get your upper securing bolt started and do not tighten all the way down, then put the nuts on the pedal to secure it to the firewall and tighten all the way and then lastly tighten the upper bolt down good and then install the clip into the master cylinder rod securing pin.

Check the operation of the pedal to make sure its nice and smooth without hanging up. If it does you will need to make adjustments to either your upper securing bolt hole location or your holes on your firewall until it comes out nice and square and allows proper operation. All in all it took me about 3 hours total to do it. Its a lot of back and forth, try this and try that to do it. Then you can mount the fluid reservoir bracket on the strut tower where a black fill plug is located, just remove it and use one of the 10mm bolts with the pedal.

Here are the pics of the outcome and you can kinda see the welded bracket and how it mates against the firewall and where the pedal sits. I lined mine up to where its a little farther away from the brake pedal and for those of you that do road racing this is a good thing to keep you from taping the brakes instead of the clutch or with the clutch. I like it and it came out good and pedal height is perfect.

Thats about all. Its really not that hard and to me its better to do it this way than convert your tranny to cable. You never have to worry about breaking a clutch cable and you can use a heavy clutch and you will never know it.

i need to do this with my car, i´m tired of that hard clutch pedal

i need to do this with my car, i´m tired of that hard clutch pedal

Back to top

Back to top